Oil scavenger for gas-oil separator of engine

A technology for oil and gas separators and engines, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of backward oil absorption and discount of oil and gas separation effect, and achieve the effect of preventing backward oil absorption, ensuring the effect of oil and gas separation, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

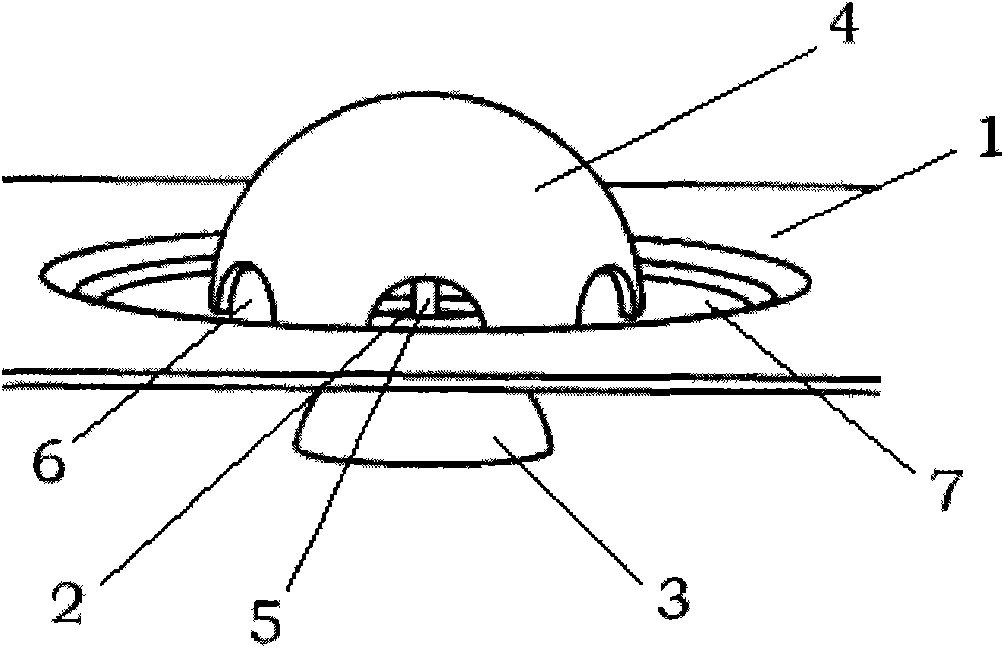

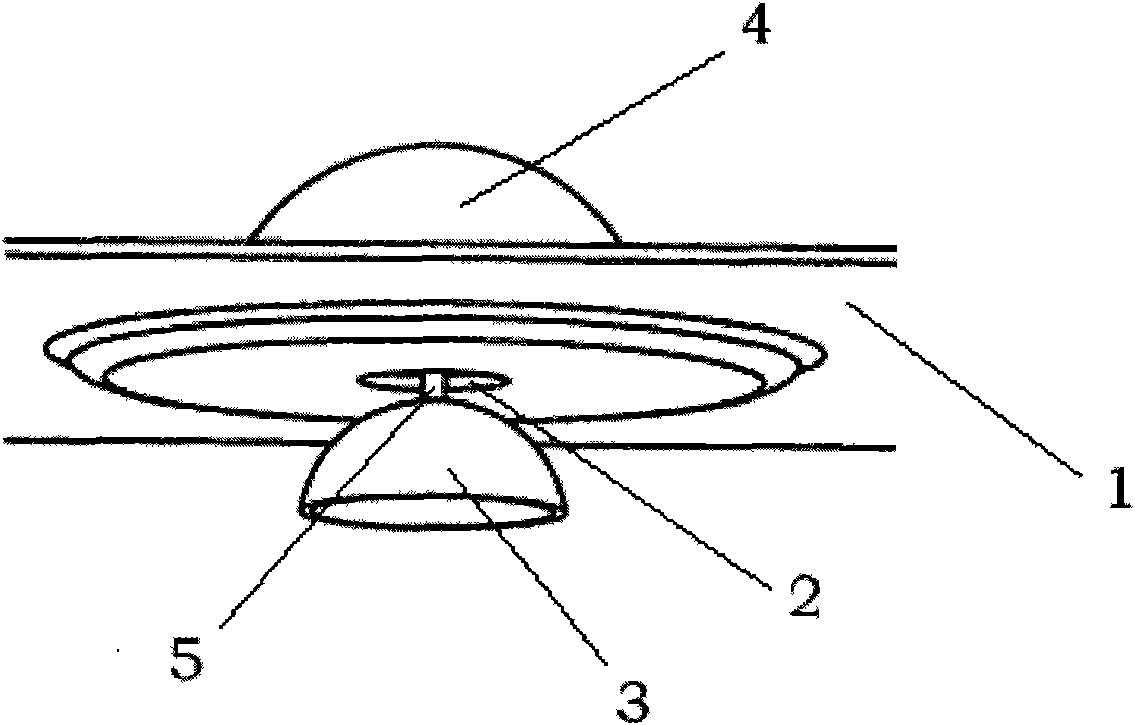

[0017] Such as figure 1 , 2 As shown, the oil return device of the engine oil-gas separator of the present embodiment includes a flat plate 1 for separating the intake manifold and the crankcase, and the flat plate 1 is provided with a circular oil return hole 2, and the oil return The bottom of the hole 2 is provided with a self-closing valve 3 that can automatically block the oil return hole 2 under the action of the upward airflow of the crankcase. The self-closing valve 3 is umbrella-shaped, installed at the bottom of the oil return hole 2 and can Moving up and down along the axis of the oil return hole, the diameter of the oil return hole 2 is smaller than the diameter of the bottom of the self-closing valve 3 . The top of the self-closing valve 3 is fixedly connected with an umbrella-shaped booster component 4 through a threaded rod 5 , the bottom of the booster component 4 has an oil return gap 6 , and the booster component 4 is located above the oil return hole 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com