Solid-liquid separation system for aluminum paste production and application method thereof

A technology of solid-liquid separation and aluminum-silver paste, applied in separation methods, filtration separation, dispersion particle separation, etc., can solve the problems of workshop production environment and atmospheric environment impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

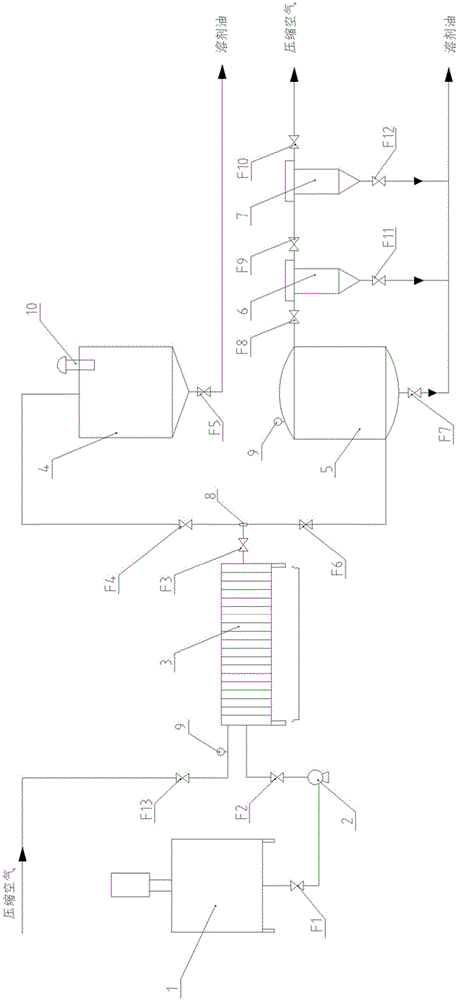

[0026] Such as figure 1 As shown, the present invention discloses a solid-liquid separation system for the production of aluminum-silver paste, which mainly includes an aluminum-silver paste disperser 1, a material delivery pump 2, a filter press 3, an oil storage tank 4, a coalescence separator 5, a second The primary oil-gas separator 6 and the second-stage oil-gas separator 7.

[0027] The aluminum-silver paste disperser 1, the material conveying pump 2 and the filter press 3 communicate with the first valve F1 and the second valve F2 through pipelines, and the filtrate produced in the process of filtering materials by the filter press 3 passes through the pipeline and the third valve F3, the three-way pipe 8, and the fourth valve F4 enter the oil storage tank 4 for collection. The oil storage tank 4 is a closed tank body, the top of which is connected with a breather valve 10, and the bottom is connected with a fifth valve F5 and an oil discharge pipe.

[0028] The mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com