Lens regulation module

A technology for adjusting modules and lenses, applied in installation, optics, instruments, etc., can solve problems such as image out-of-focus, failure to meet different needs of projector space planning, large cumulative tolerance, etc., and achieve the effect of reducing cumulative tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

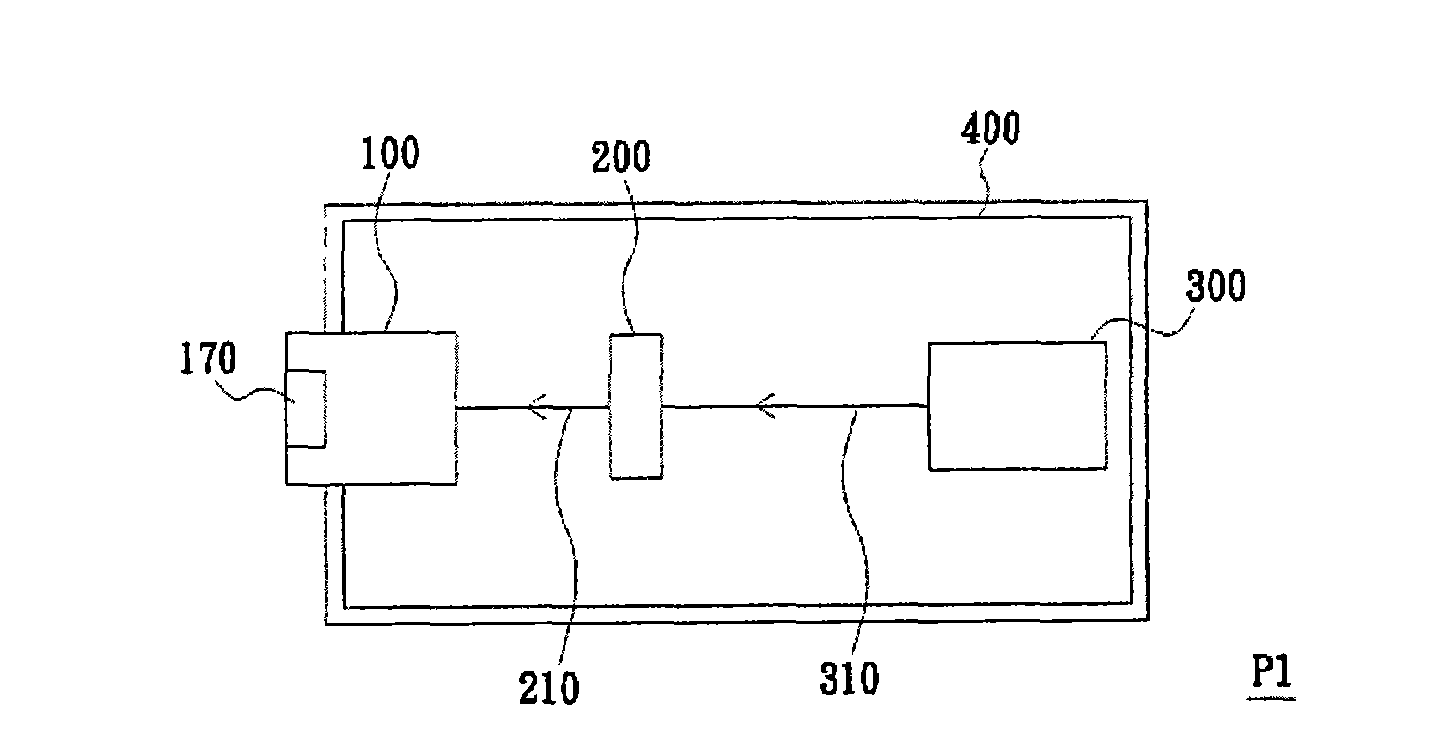

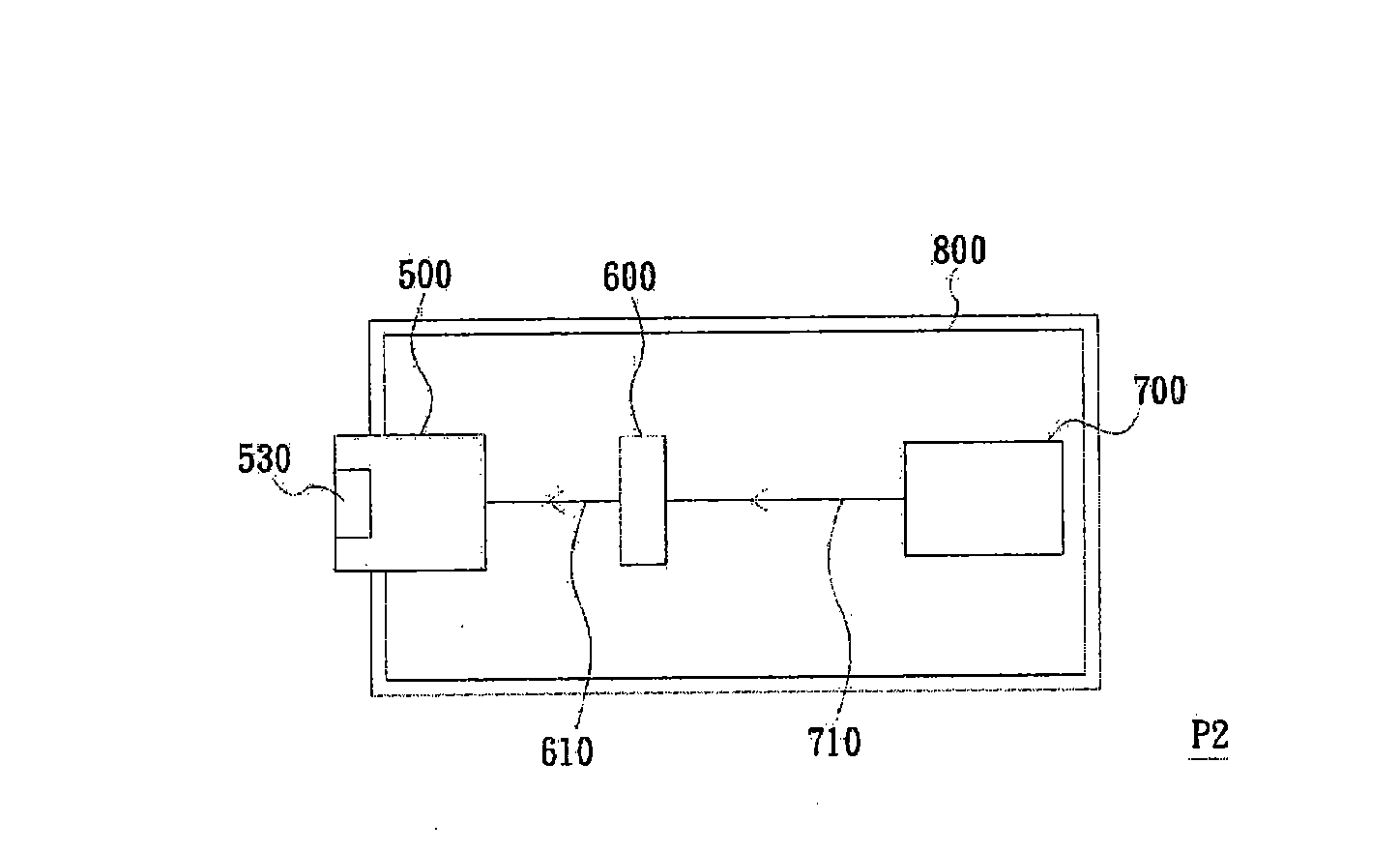

[0077] image 3 A schematic diagram of a projector according to the first embodiment of the present invention is shown. Please refer to image 3 , the projector P2 of this embodiment includes a lens adjustment module 500 , a light valve 600 , an illumination module 700 and a cover 800 . The lighting module 700 disposed in the cover body 800 provides an lighting beam 710 . The light valve 600 is disposed inside the cover body 800 and located on the transmission path of the illumination beam 710 . The light valve 600 converts the illumination beam 710 into an image beam 610 . The lens adjustment module 500 is disposed on the cover body 800 , and a lens 530 of the lens adjustment module 500 is located on the transmission path of the image beam 610 to project the image beam 610 to a screen (not shown).

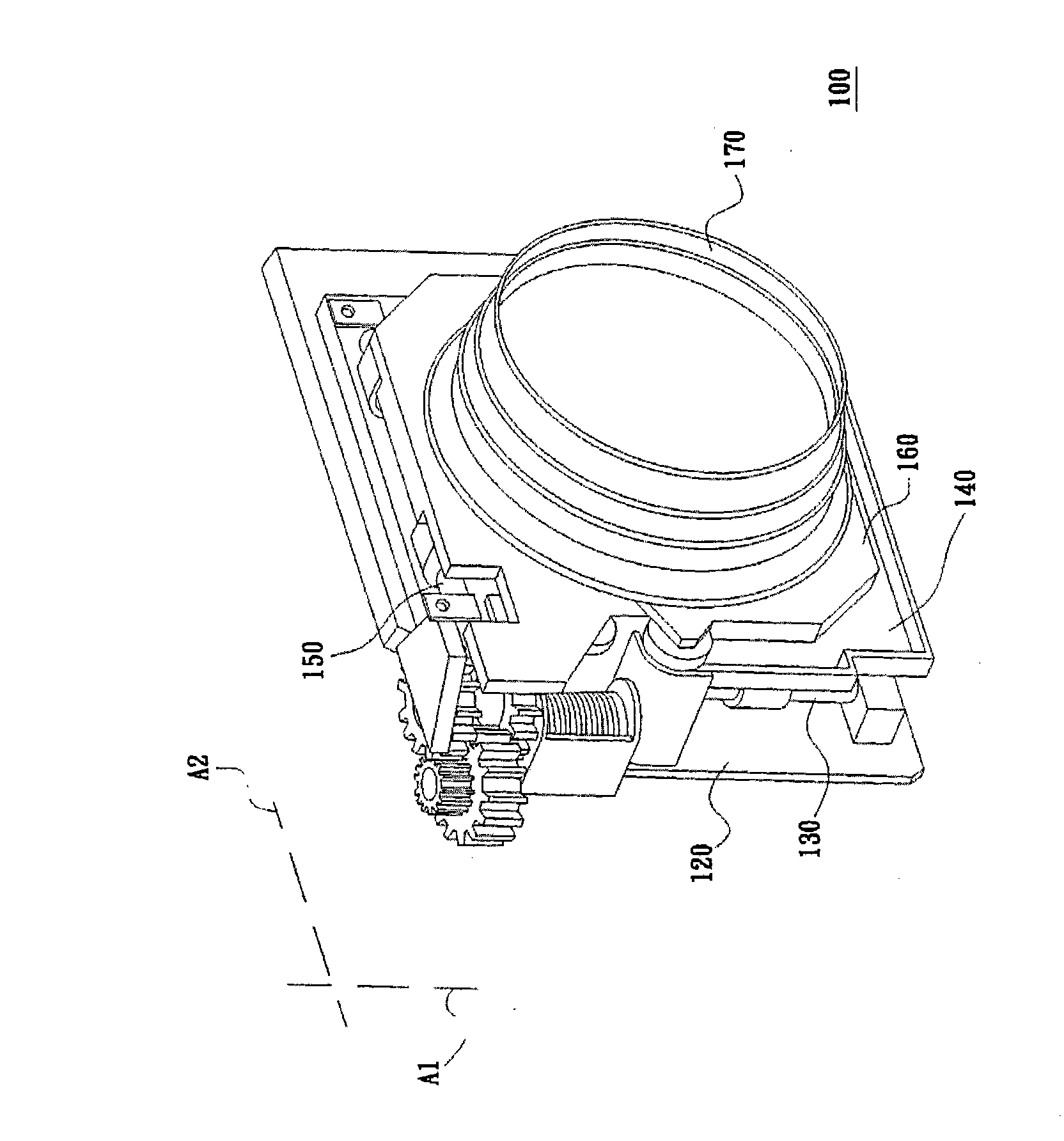

[0078] Figure 4A draw image 3 Combination diagram of the lens adjustment module, Figure 4B draw Figure 4A An exploded schematic of the lens adjustment module. Figure...

no. 2 example

[0092] Figure 9 An exploded view of a lens adjustment module according to a second embodiment of the present invention is shown. Figure 10A draw Figure 9 A detailed exploded schematic of the carrier plate. Figure 10B draw Figure 9 Another detailed exploded schematic diagram of the carrier plate. Figure 11 draw Figure 9 A detailed exploded schematic diagram of the adjustment device. Figure 12 draw Figure 9 A schematic diagram of the connection relationship between the adjustment device and the carrier plate. It is worth noting here that, for the sake of illustration, Figure 12 Only some of these components of the adjustment device 540' are shown schematically. Please refer to Figure 4B , Figure 5 , Figure 6A , Figure 9 , Figure 10A , Figure 10B and Figure 11 The main difference between the lens adjustment module 500' of this embodiment and the lens adjustment module 500 of the first embodiment lies in the appearance and configuration of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com