Methods for producing fermentation products

一种发酵产物、生物体的技术,应用在发酵、生物燃料等方向,能够解决耐受性限制、除去毒素困难、耗时且昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

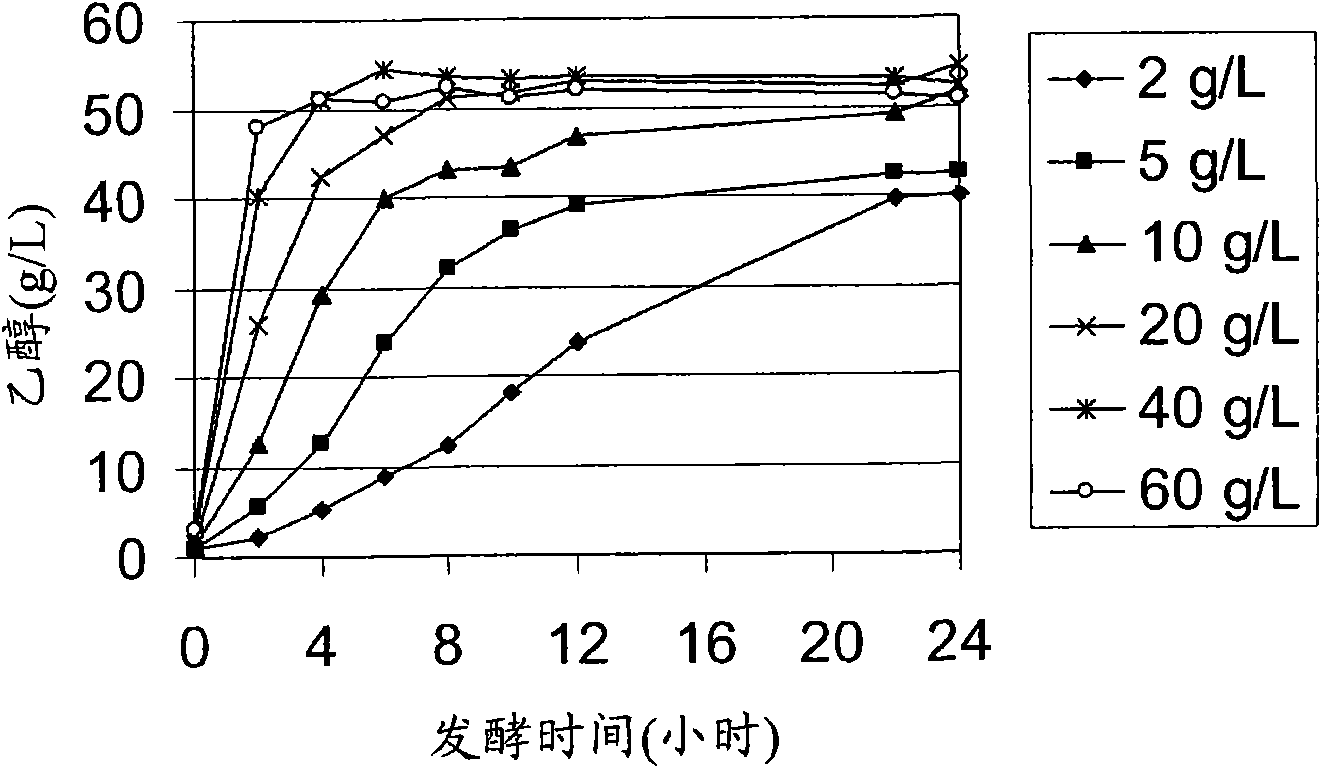

[0374] Ethanol production for high cell counts

[0375] The effect of high yeast pitch (cell count) and cell recirculation on ethanol production was tested by inoculating filtered pretreated corn stover (PCS) enzymatic hydrolyzate at various starting yeast cell concentrations. At 24 and 48 hours after the start of the fermentation, the cells were recirculated by centrifugation, the spent hydrolyzate was removed, and fresh hydrolyzate was added.

[0376] method:

[0377] Unwashed PCS (acid-catalyzed, steam-exploded, The National Renewable Energy Laboratory, Golden , CO) hydrolyzed for 72 hours. After hydrolysis, the slurry was centrifuged at 3000 rpm for 10 minutes and the supernatant was collected by filtration using a 0.45 micron Whatman filter.

[0378] Varying amounts of RED STAR ranging from 1 g stem cells / L to 50 g stem cells / L were added to wells of 24-well cell culture plates (Whatman International Ltd., Florham Park, NJ) TM yeast. Add 4 mL of PCS Enzymatic Hyd...

Embodiment 2

[0383] Ethanol production at low cell counts

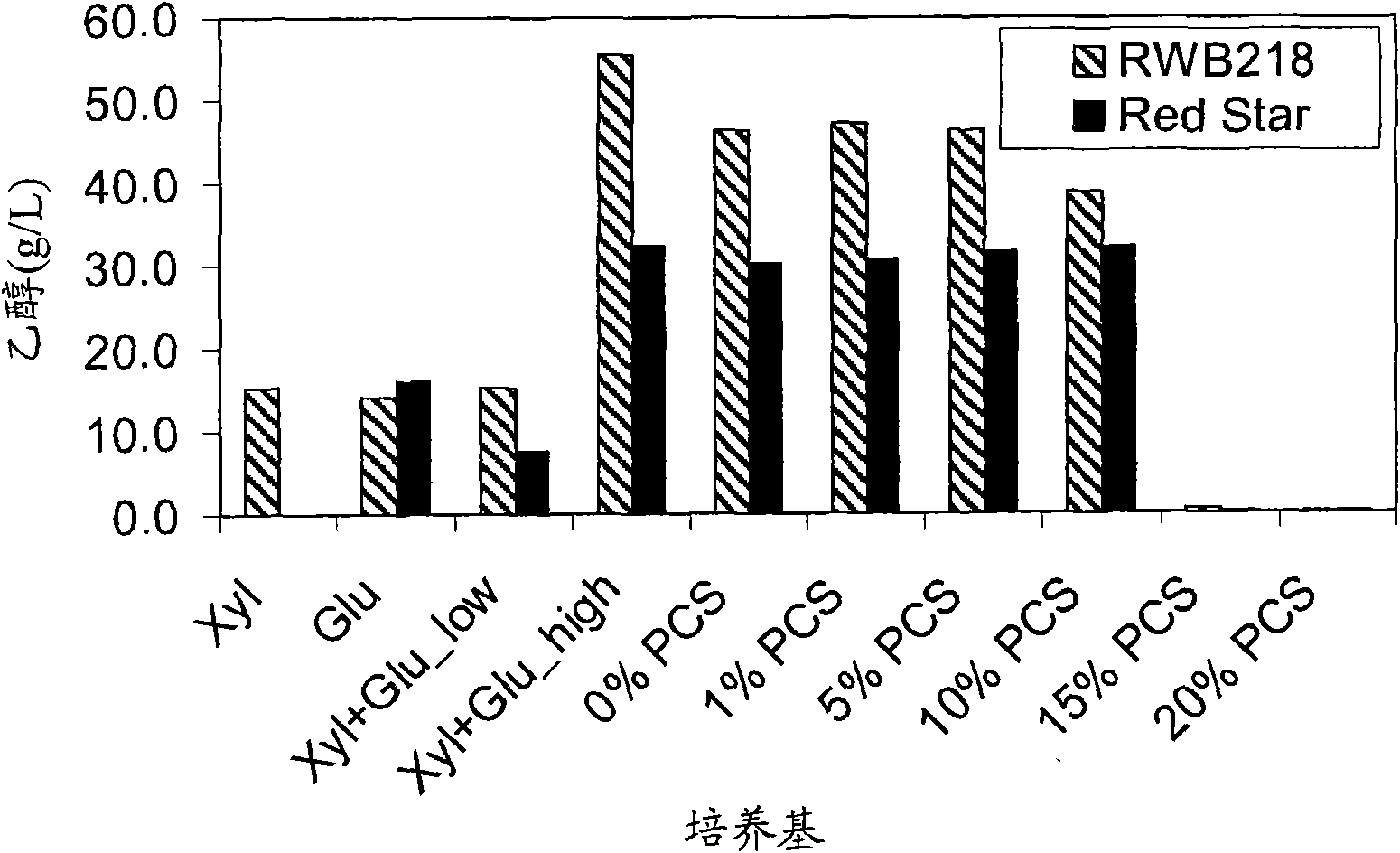

[0384] The effect of various amounts of sugar solution and filtered pretreated corn stover (PCS) enzymatic hydrolyzate on ethanol production in batch fermentation with different yeast strains was tested. The results are summarized in figure 1 middle.

[0385] method:

[0386] Pass ten different media through RED STAR TM Batch fermentation with yeast and RWB218 (Nedalco) to produce ethanol. Media 1 to 5 were glucose and xylose solutions supplemented with 0.5% (w / v) yeast extract and 1% (w / v) peptone. Media 6 to 10 were filtered unwashed pretreated corn stover (fuwPCS) enzymatic hydrolyzates with varying levels of total solids. The sugar levels of media 5 to 9 were adjusted so that the xylose and glucose concentrations were equivalent to those found in the fuwPCS hydrolyzate at 20% total solids to test the resistance of the strains to different levels of inhibition. All media were filter sterilized.

[0387] Medium 1: onl...

Embodiment 3

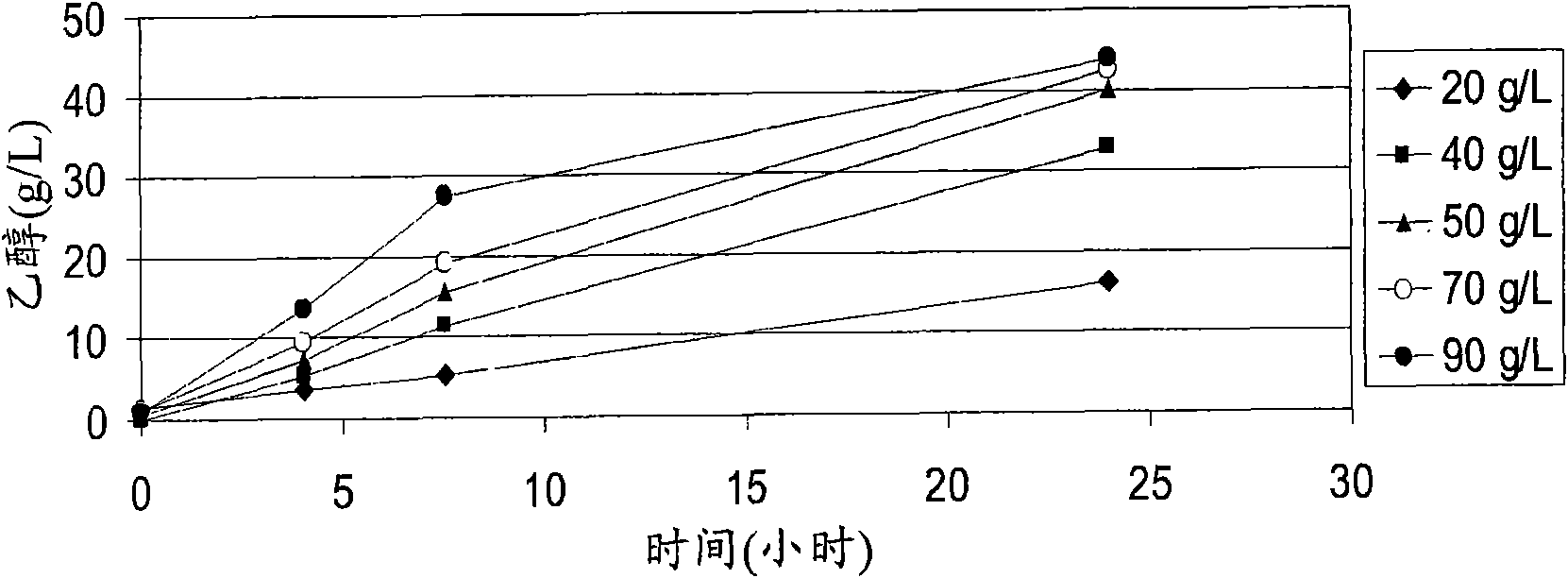

[0400] Ethanol production for high cell counts

[0401] High RED STAR was tested by inoculating filtered pretreated corn stover (PCS) enzymatic hydrolyzate at various starting yeast cell concentrations TM Effect of yeast feeding (cell count) on ethanol production in batch fermentation. The results are summarized in figure 2 middle.

[0402] method:

[0403] Unwashed PCS (acid catalyzed from The National Renewable Energy Laboratory, Golden, CO) was digested at 50°C, pH 5.0 using an initial solids concentration of 20% (w / w) and 50 mg Cellulase Preparation A / g cellulose. , pretreated corn stover) hydrolyzed for 120 hours. After hydrolysis, the slurry was centrifuged at 3000 rpm for 10 minutes using a Beckman-Coulter countertop centrifuge to separate the solids. The resulting liquid hydrolyzate was supplemented with nutrients: yeast extract and peptone at a level of 5 g / L each, and passed through a 250 mL nalgene bottle with a working volume of 150 mL using a shaking inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com