Coke oven offtake piping system

A technology for discharging pipelines and coke ovens, which can be used in coke ovens, coke oven heating, dry distillation gas discharge devices, etc., and can solve problems such as no great progress in flow rate control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

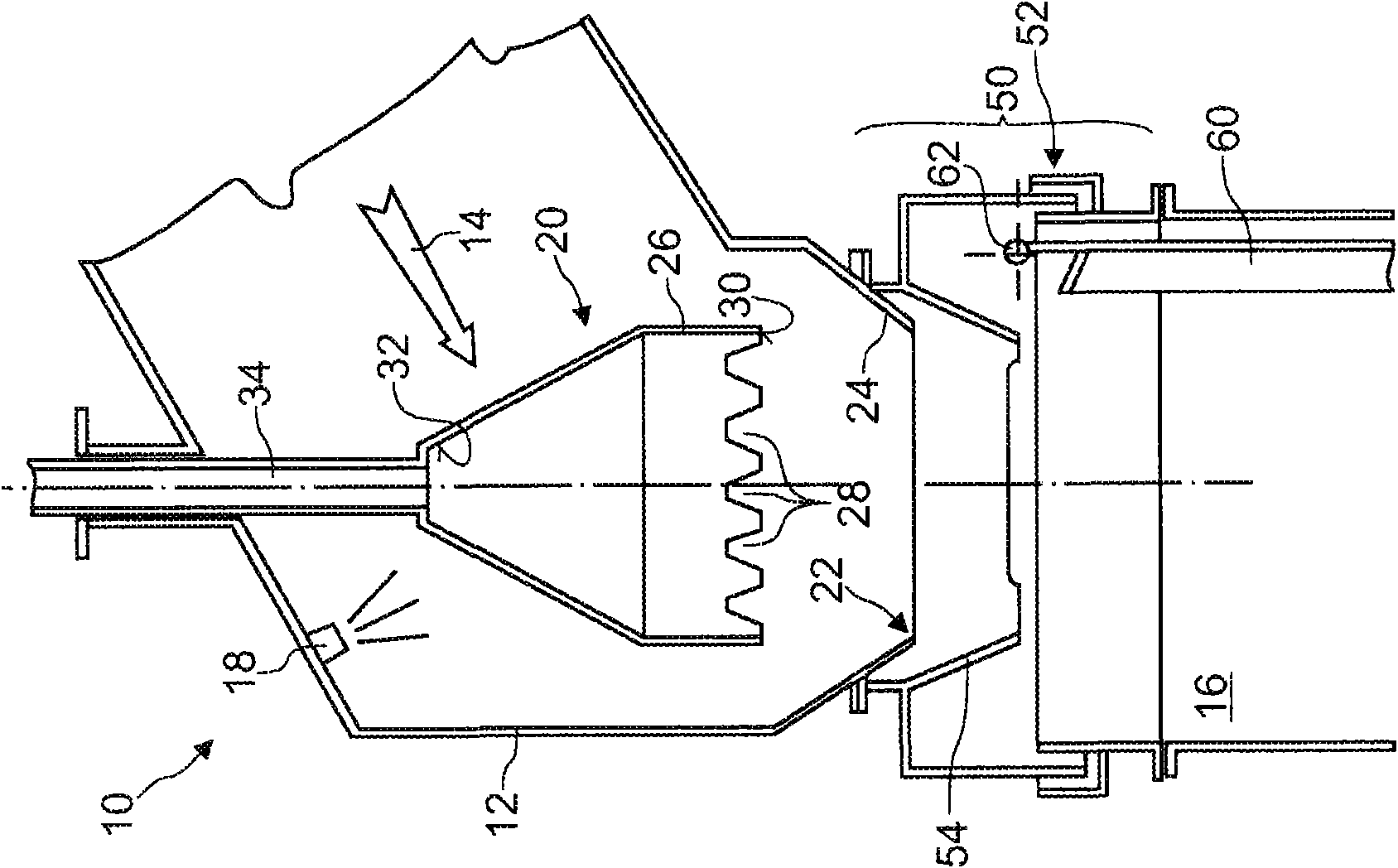

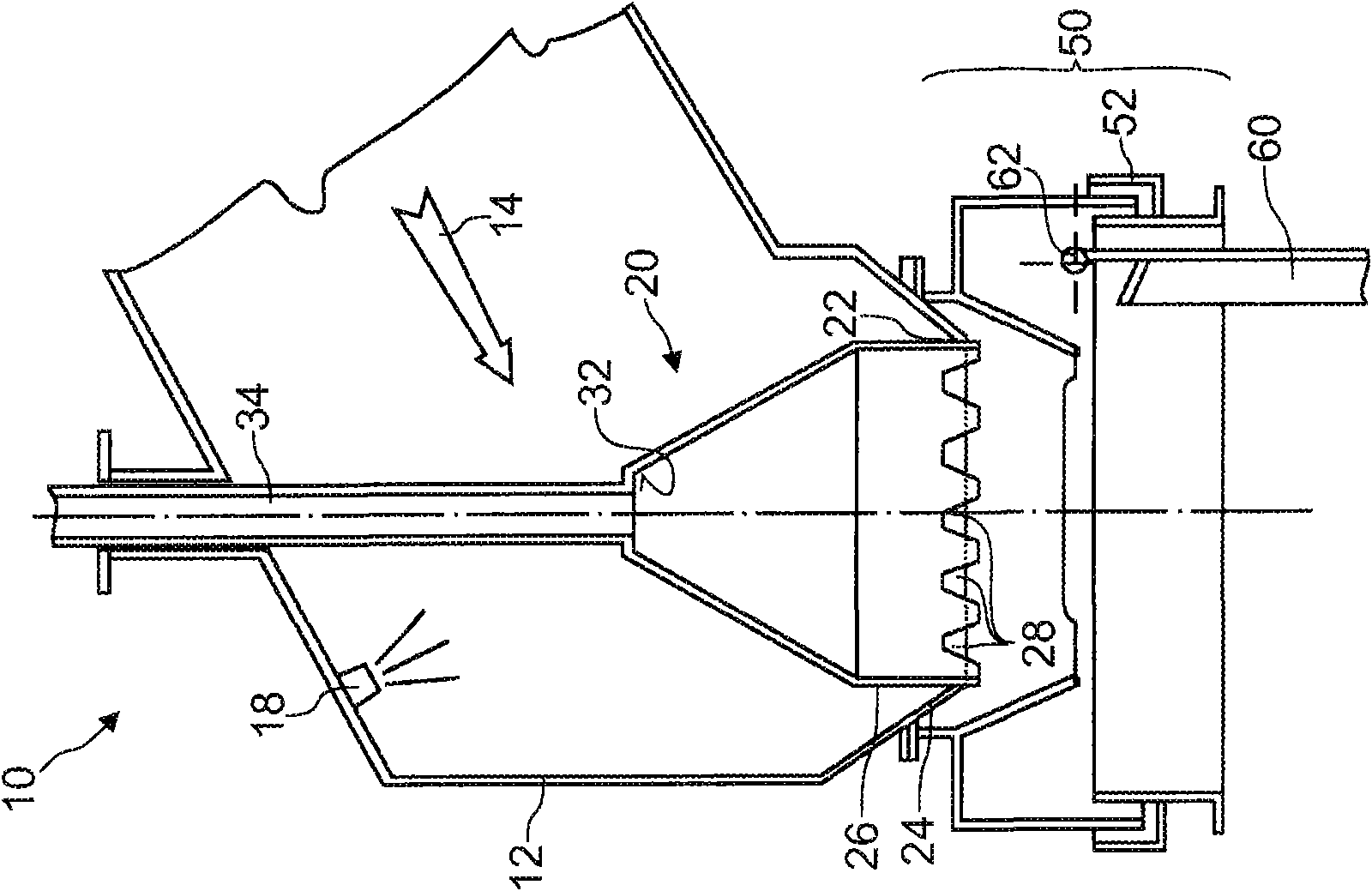

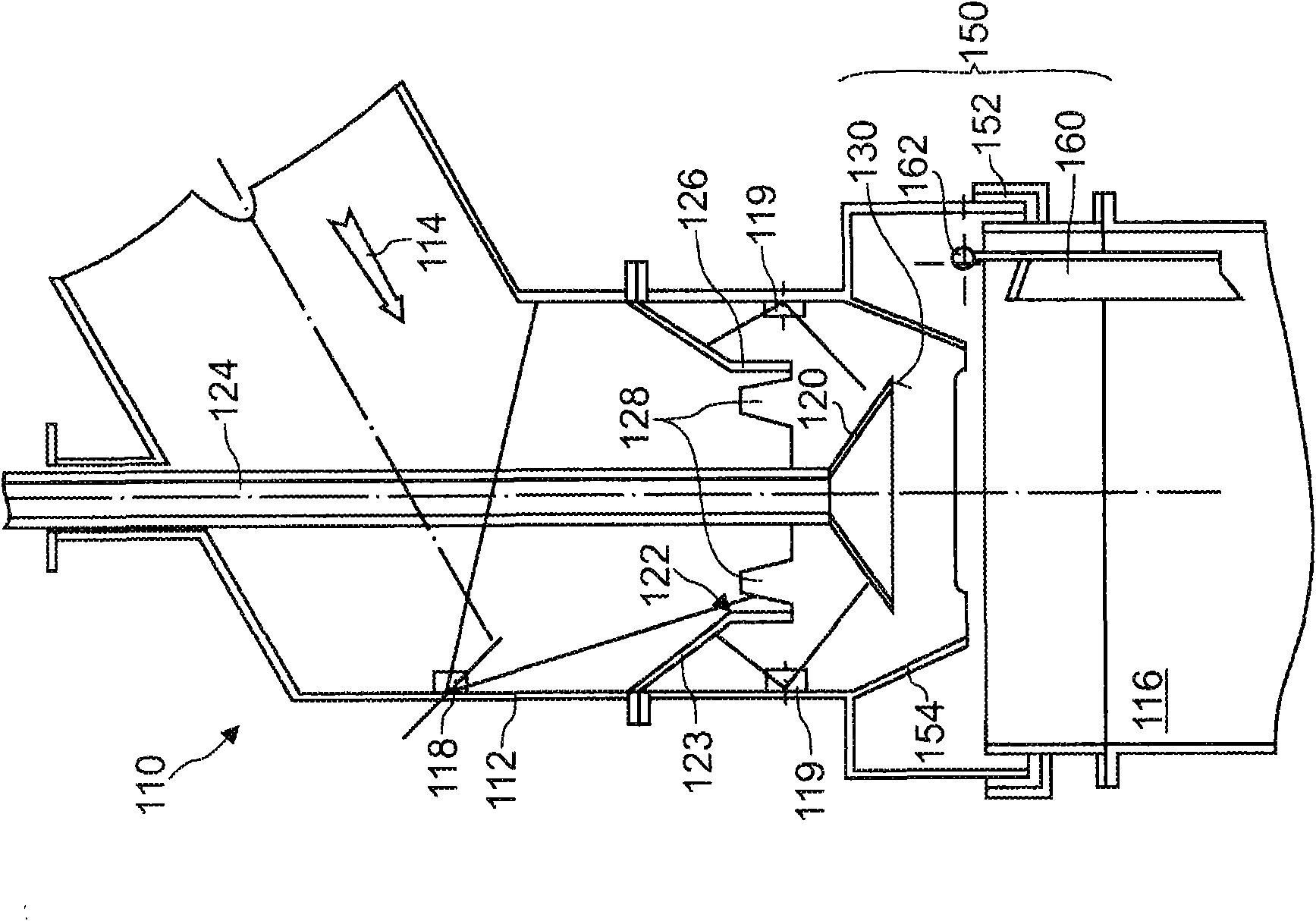

[0036] figure 1A first embodiment of a coke oven discharge piping system 10 according to the invention is shown. It includes piping assemblies for conveying untreated distillate gas from individual coke oven chambers to accumulation tubes. In this embodiment, the duct assembly includes a standpipe (not shown) whose bottom is connected to the top of a coke oven (not shown), such as a slot-type chamber of a coke oven battery. Reference numeral 12 designates a gooseneck (bent pipe) for conveying untreated coke oven gas (arrow 14) from the upper part of the standpipe to the accumulation pipe 16 of the coking plant, which typically runs the entire length of the coke oven battery . Conventionally, these piping pieces may have refractory linings. The gas discharged from the furnace chamber at a temperature of about 700°C to 800°C is advantageously cooled in the gooseneck 12 to a temperature of 80-100°C by means of one (or more) nozzles 18 (spraying a process fluid such as ammonia)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com