A three-phase foam composite flooding system and its application

A composite flooding and system technology, which is applied in the direction of production fluid, drilling composition, wellbore/well components, etc., can solve the problems of single gas and limited application, so as to reduce the oil-water mobility ratio, improve the sweep coefficient, The effect of foam stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

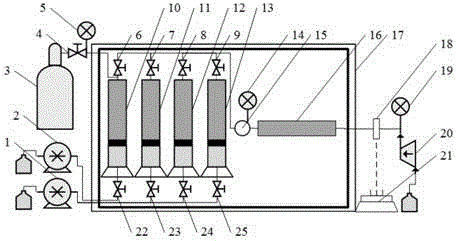

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Three-phase foam composite oil displacement system, which is composed of oil displacement system solution and nitrogen at a volume ratio of 1:1, which are injected into formations or cores alternately in sequence.

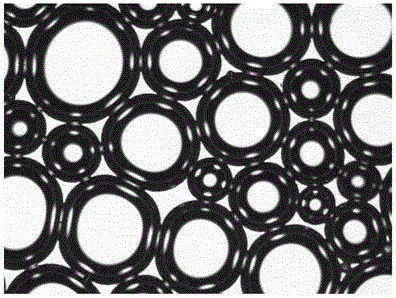

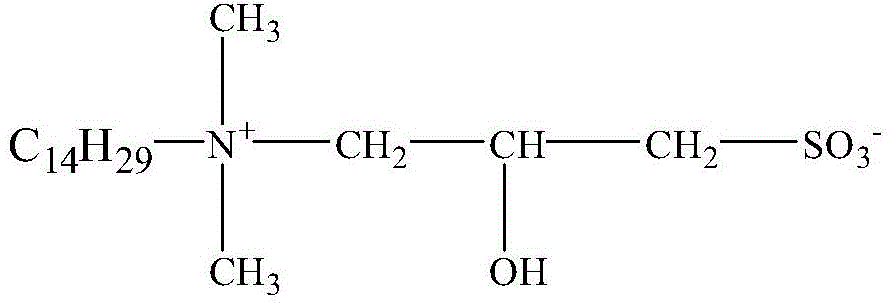

[0050] Oil displacement system solution: foaming agent is tetradecyl hydroxysulfobetaine surfactant (THSB), and the percentage of foaming agent accounting for total oil displacement system solution mass is 0.2%; Foam stabilizer is made of nonionic polyacrylamide It is composed of phenolic resin jelly dispersion 1:1, wherein the molecular weight of non-ionic polyacrylamide is 6 million, the degree of hydrolysis is 2%, the size of the jelly dispersion is 50-60 μm, and the foam stabilizer accounts for the mass percentage of the total oil displacement system solution 0.2%; the rest is water.

[0051] The above oil displacement system solution is abbreviated as: 0.2%THSB+0.1%NPAM+0.1%DPG+residual water, the same expression is also used in the following...

Embodiment 2

[0059] As described in Example 1, the difference is: the length × width × height of the basic parameters of the three-layer heterogeneous core = 30cm×4.5cm×4.5cm, and the permeability of the high, middle and low layers is 5 μm, 2 μm, 0.5 μm. Oil flooding results: the water flooding recovery rate is 43.6%, the ultimate recovery rate after three-phase foam composite flooding reaches 89.6%, and the enhanced oil recovery rate is 46.0%.

Embodiment 3

[0061] As described in Example 1, the difference is: the injection slug is the first 0.15PV oil displacement system solution, followed by alternate injection of 0.15PV nitrogen gas (2 times); the oil displacement result: the water flooding recovery rate is 37.0%, three-phase After foam composite flooding, the ultimate recovery rate reaches 70.1%, and the enhanced oil recovery rate reaches 33.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com