Coaxial connector

A coaxial connector, axial technology, applied in the direction of connection, two-pole connection, two-part connection device, etc., to achieve the effect of a wide frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

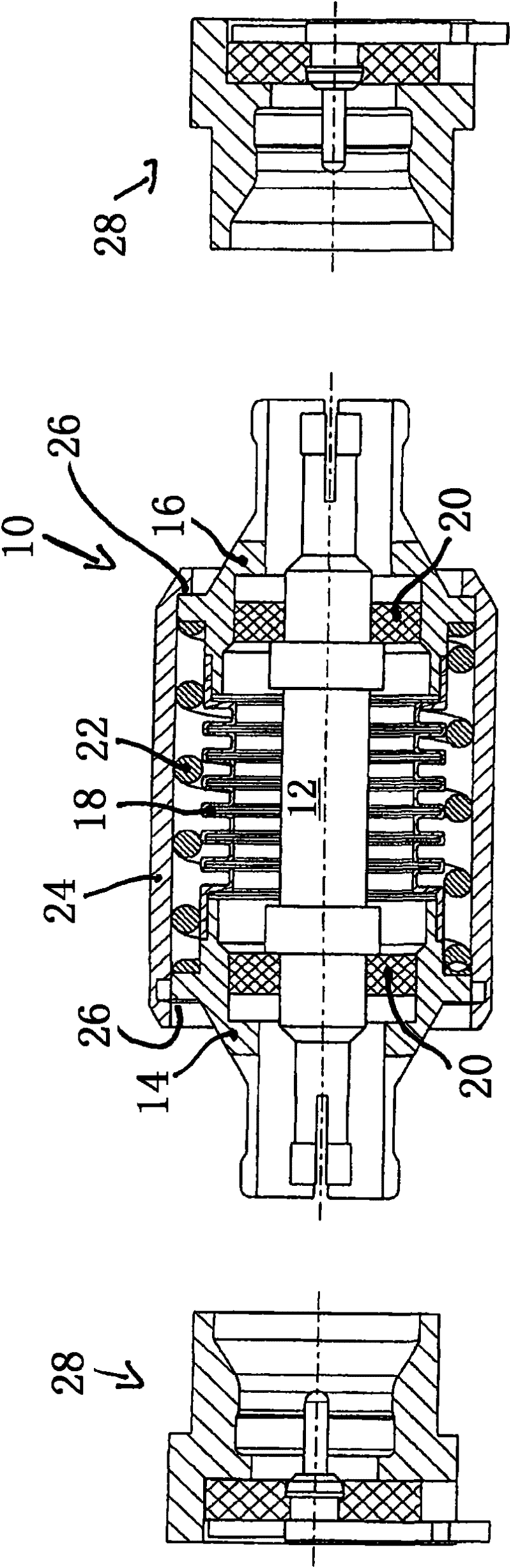

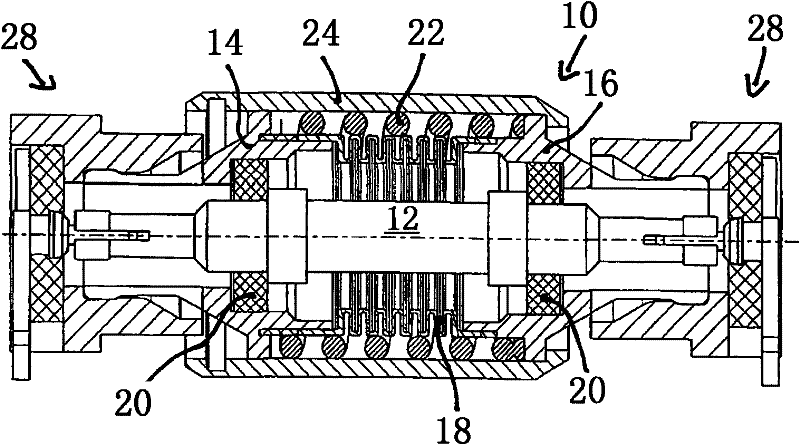

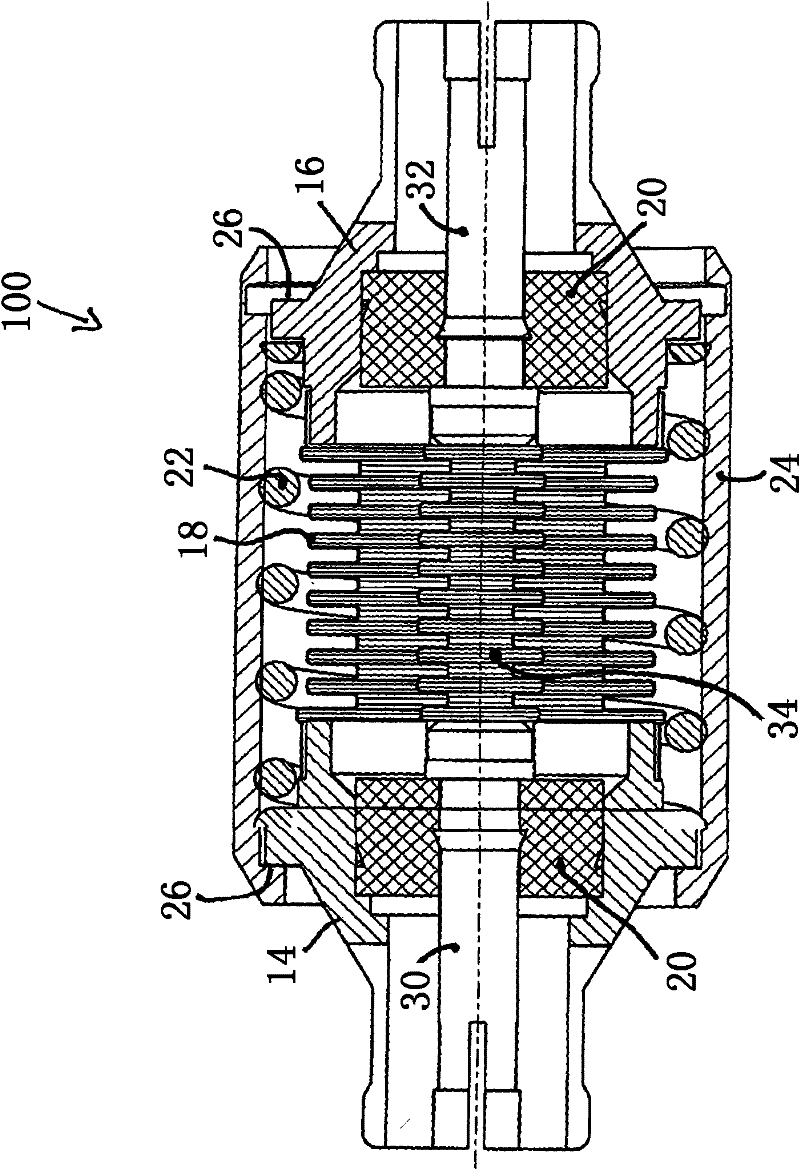

[0021] figure 1 with figure 2 The illustrated first preferred embodiment of the coaxial connector 10 according to the present invention includes a central conductor 12 and an outer conductor, the outer conductor being composed of a first outer conductor portion 14 and a second outer conductor portion 16, the first outer conductor portion 14 forms the first end of the outer conductor for insertion, and the second outer conductor portion 16 forms the second end of the outer conductor for insertion. Between the two outer conductor parts 14 and 16, the outer conductor is in the form of a telescopic outer conductor bellows 18. In this way, the two outer conductor portions 14, 16 can move relative to each other in the axial direction. The central conductor 12 is in a rigid form, and the central conductor 12 is held in the two outer conductor parts 14 and 16 by the insulating disk 20 so that the two outer conductor parts 14 and 16 can move relative to the central conductor 12 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com