Elliptical vibrating screen with multi-section polygonal line screen surface

A technology of elliptical vibration and sieve surface, which is applied in the direction of filter screen, solid separation, grid, etc., and can solve the problems of small amount of processed materials, large impact force of sieve plates, and easy accumulation of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

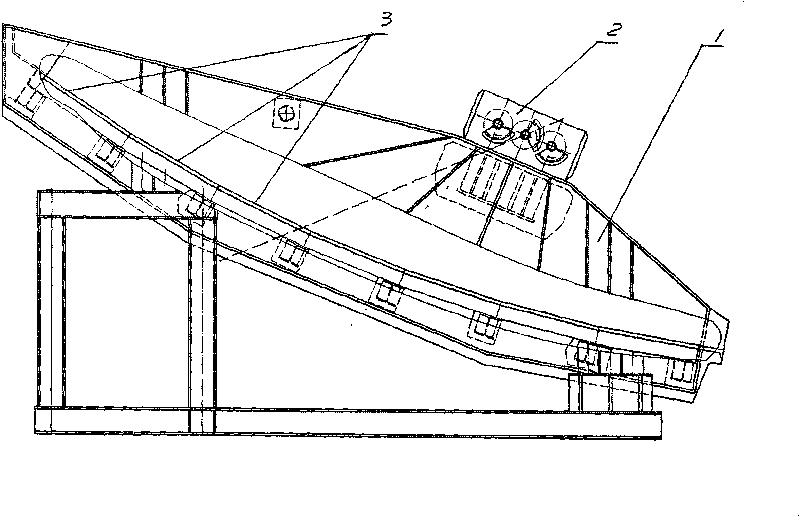

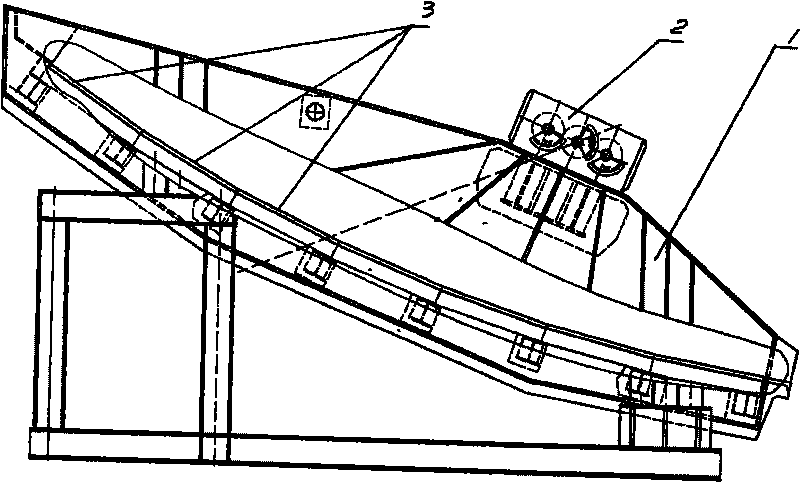

[0005] The present invention is described in detail with reference to the above drawings. A three-axis elliptical vibrator 2 is installed on the top of the screen box 1, and the screen surface is composed of 7 screen plates 3 connected to each other with different inclination angles. The inclination angle between each sieve plate and the horizontal plane of the present invention gradually becomes smaller from the feed end to the discharge end. The inclination angle of each of the 7 sieve plates at the discharge end is a fixed value, generally 3-6 degrees. This kind of sieve surface has a fast material flow rate, a thin material layer, and a stable material flow rate ratio on each section of the sieve surface, showing a balanced micro-increase effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com