Self-loading and unloading method of rear counterweight of main engine of crawler crane

A crawler crane and rear counterweight technology, which is applied to cranes, cargo handling equipment, ship accessories, etc., can solve the problems of high manufacturing cost, complex structure, and high installation requirements of hydraulic cylinder 2, and achieve the effect of low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

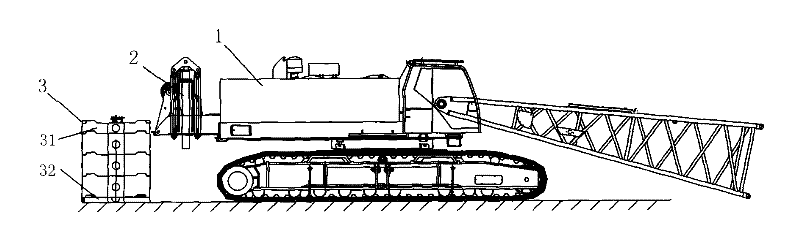

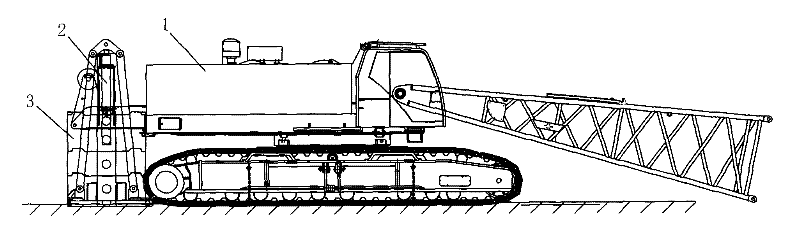

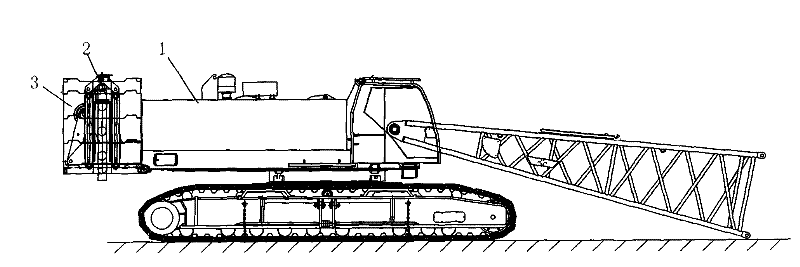

[0021] The structural features of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 4 to Figure 6 As shown, the self-loading and unloading method of the rear counterweight of the crawler crane of the present invention comprises the following steps:

[0023] a. The main luffing mast 4 of the crawler crane is arranged so that the main luffing mast 4 and the main platform 1 form an acute angle; The specific method is: pull up the telescopic piston rod of the oil cylinder 5 to increase or decrease the inclination angle between the main luffing mast 4 and the main platform 1 to support the main luffing mast 4 .

[0024] b. Use the platform pulley block connected to the mast pulley block 6 to lift the rear counterweight 3, and hang the rear counterweight 3 on or hang from the rear counterweight lug 11 of the main platform 1.

[0025] In this step, the platform pulley block 7 on the main platform 1 mainly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com