Injection mold for tool post

A technology of injection molds and knife bases, which is applied to household appliances, other household appliances, and threaded products, etc., can solve the problems of mold design and manufacturing requirements, and achieve the effect of avoiding crash and inaccurate return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

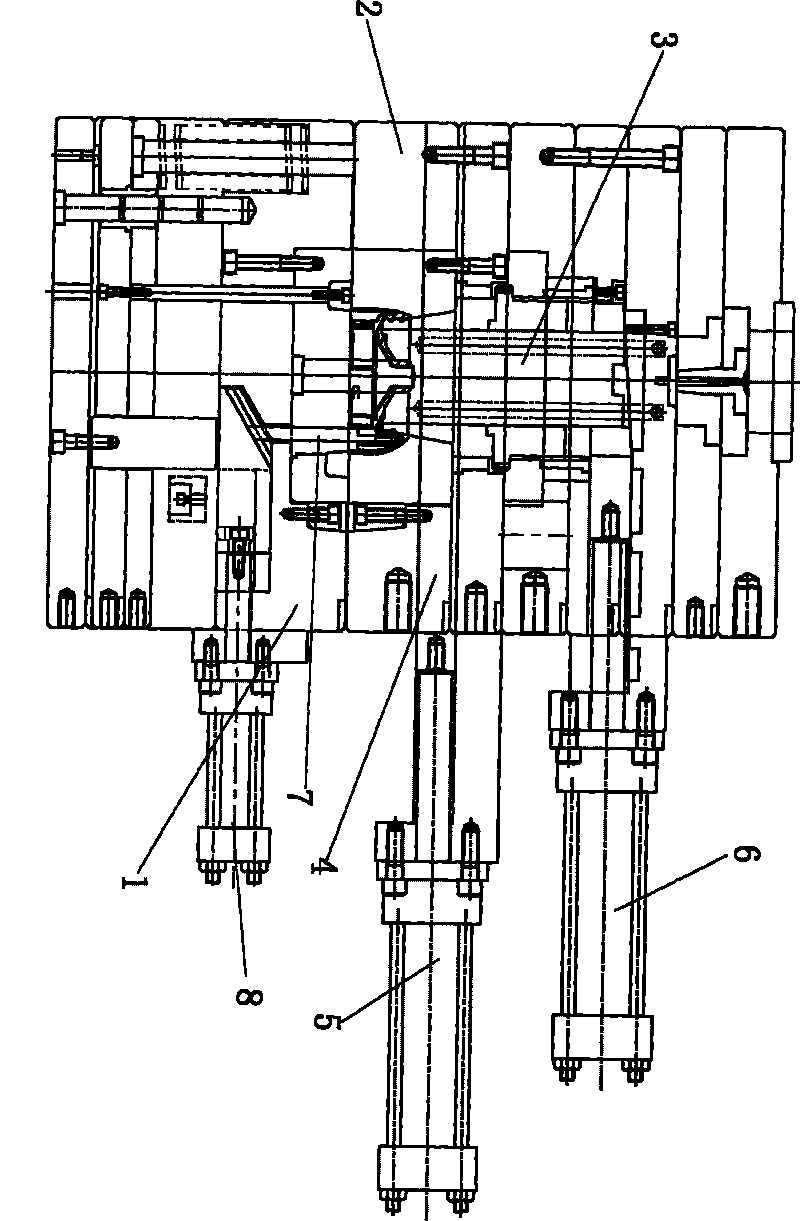

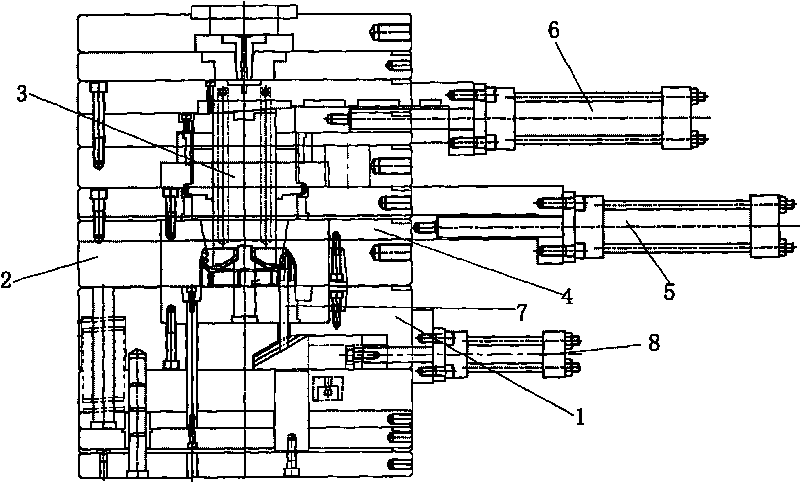

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

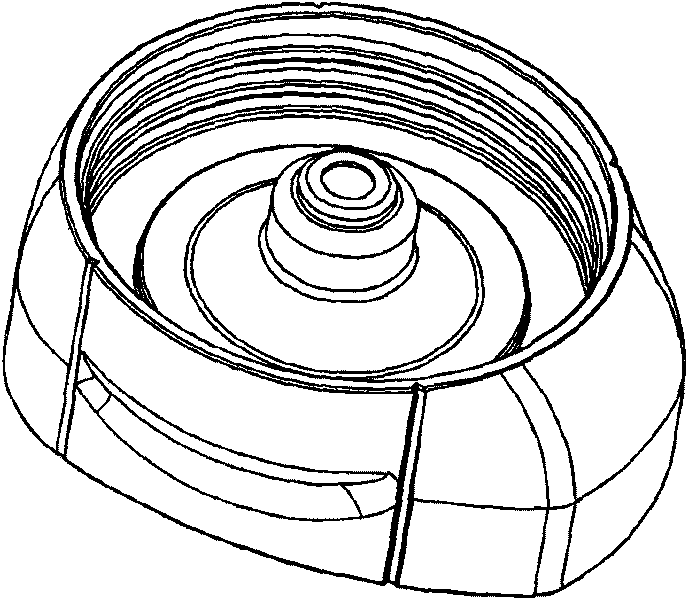

[0013] refer to figure 2 , is a schematic diagram of the structure of the tool table to be formed in the present invention, and a mounting hole for installing a micro switch is opened on the internal thread of the knife table.

[0014] refer to figure 1 , a kind of tool post injection mold, comprising a movable template 1 and a fixed template 2, the fixed template 2 is movably provided with an internal thread core sleeve 3, and the outer wall of the internal thread core sleeve 3 is engaged with a gear , the gear is meshed with a rack 4, and the rack 4 is connected with an output shaft of a rack oil cylinder 5 that drives its reciprocating linear motion;

[0015] It also includes an axial positioning oil cylinder 6 for axially positioning the internal thread core sleeve 3 and a radial positioning oil cylinder for radially positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com