Mounting structure of automobile engine

A technology of automobile engine and installation structure, which is applied in power units, vehicle parts, transportation and packaging, etc., can solve the problems of increasing installation structure cost, large space in engine compartment, and complicated installation structure, and achieves simple structure, reduced cost, and reduced cost. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

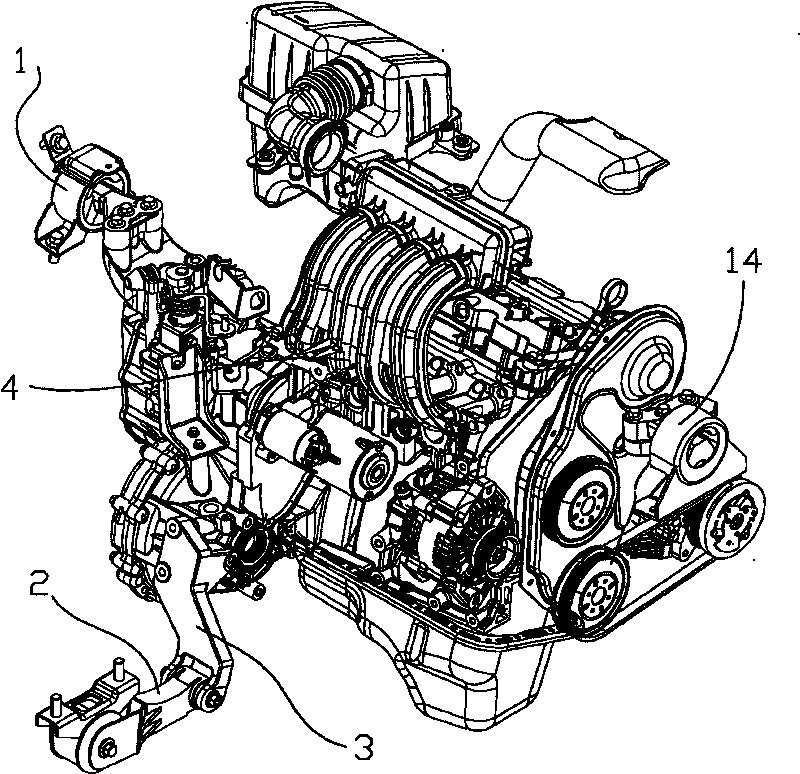

[0013] Such as figure 1 Shown, the mounting structure of this automobile engine comprises engine 4, left mount 1, right mount 14 and rear mount 2, left mount 1 and right mount 14 are bush type mounts, and bush type mounts consist of The support frame 11, the outer sleeve 8, the inner sleeve 10 and the vibration-damping rubber 7 are composed. Welded on the support frame 11. The left and right mounts 1, 14 are respectively located on the left and right sides of the engine 4, and connect the engine 4 with the vehicle body.

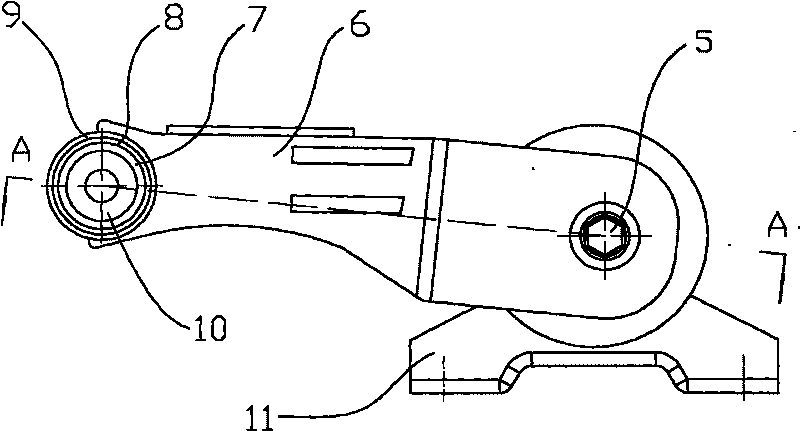

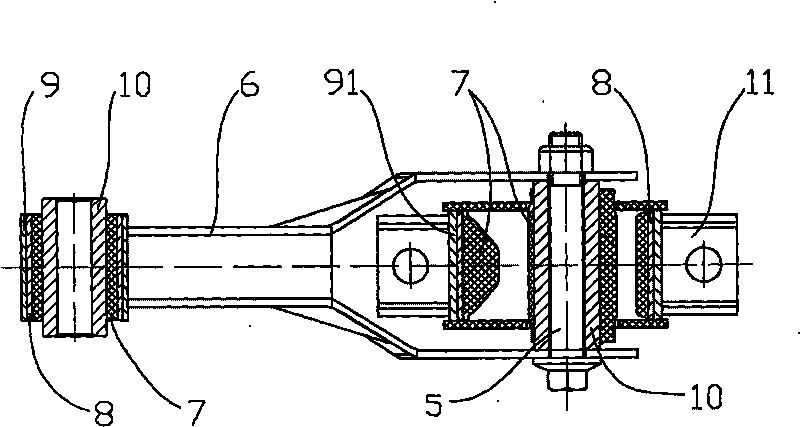

[0014] Such as Figure 2 to Figure 5 As shown, the rear suspension is mainly composed of a large damping sleeve 13, a small damping sleeve 12, a connecting plate 6 and a support frame 11. The axes of the large and small damping sleeves 13 and 12 are parallel to each other, and the outer sleeve 8, the inner sleeve The pipe 10 and the vibration-damping rubber 7 therebetween are composed, and the inner and outer casings 10, 8 are connected as a whole through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com