Method for assembling large-area safety net

An installation method and technology of safety nets, which are applied in construction, building structure, and construction material processing, etc., can solve problems such as too many fixed points, potential safety hazards, and poor splicing of safety nets, so as to prevent personnel injury accidents and property damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

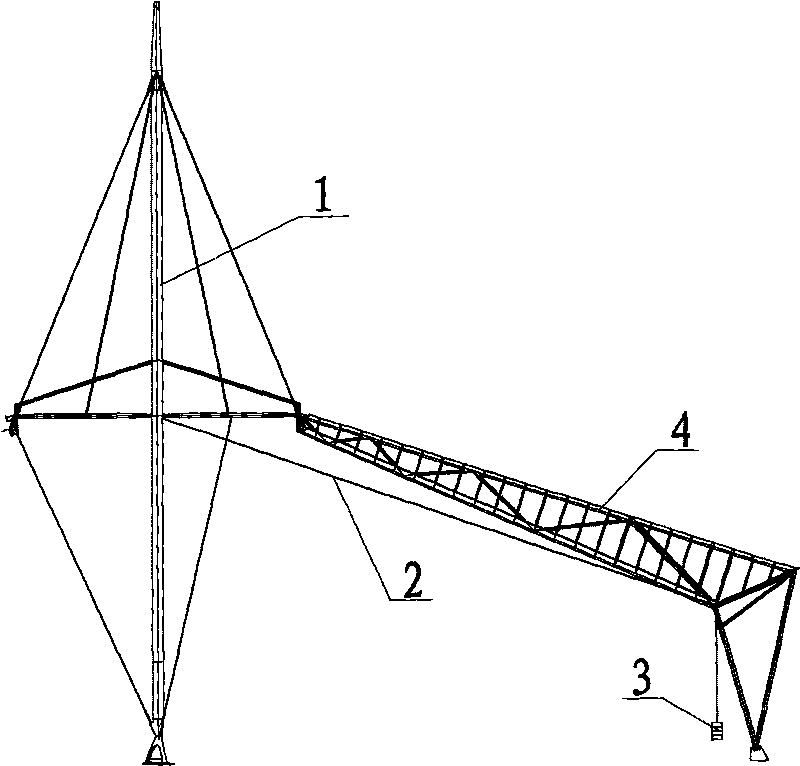

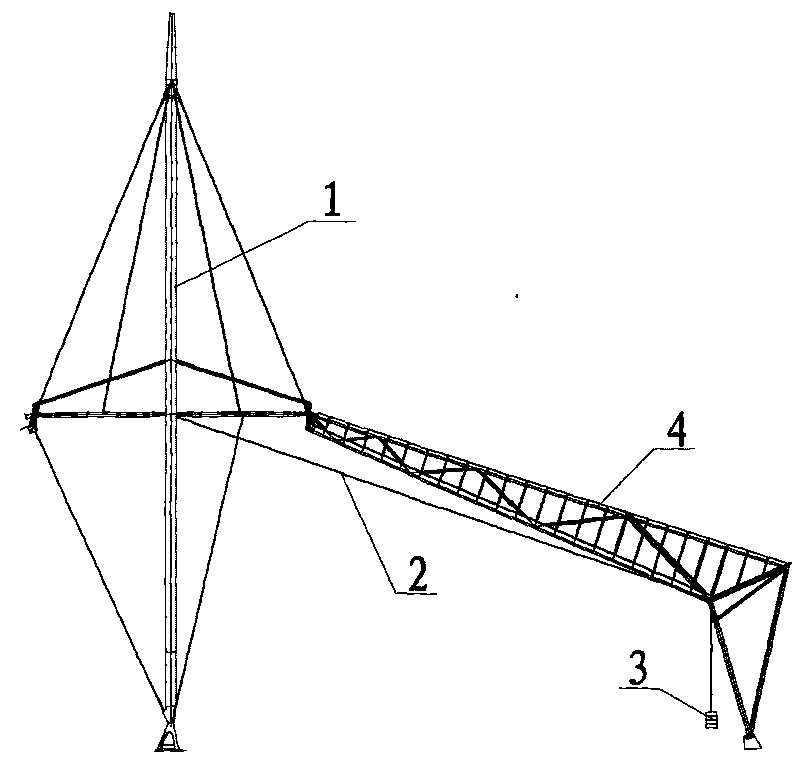

[0022] Such as figure 1 As shown, there is no safety net fixing point in the center of the ceiling of the installation hall, and there is a double row of floor-to-ceiling scaffolding at the central mast 1 of the installation hall, which is mainly used to fix steel wire ropes and hang dense mesh safety nets.

[0023] Install steel wire rope 2 and counterweight, install 58 steel wire ropes with a length of 85000mm at the position of the pressure bar on the side of the central mast 1, one end is fixed with a U-shaped buckle around the pressure bar, and the other end is pulled by a small hoist to the outer ring beam of the cornice main structure 4 And hang down to the ground, hang the cement counterweight 3 at the lower end, each counterweight is 250kg, a total of 8 pieces, use electric hoist to lift, after reaching the specified height, fold the lower end of the steel wire rope 2 to a length of 650mm, and connect it firmly and reliably with U-shaped buckles. There are three U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com