Rear registration plate lamp assembly of motorcycle

A technology for license plate lights and motorcycles, which is applied to motor vehicles, road vehicles, lighting devices, etc., can solve problems such as difficulty in drawing molds smoothly, increasing the difficulty of mold manufacturing and injection molding processes, and reducing the appearance and commerciality of rear license plate lights. Achieve the effect of improving the appearance of merchandise, easy demoulding, reliable connection and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

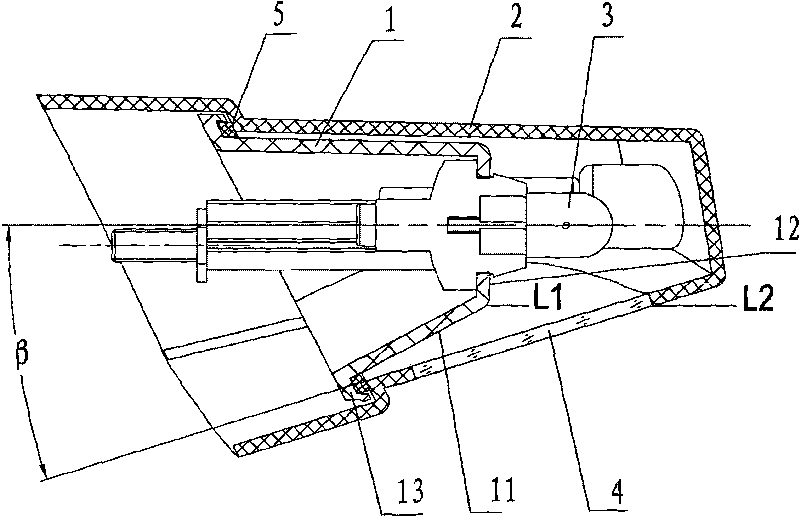

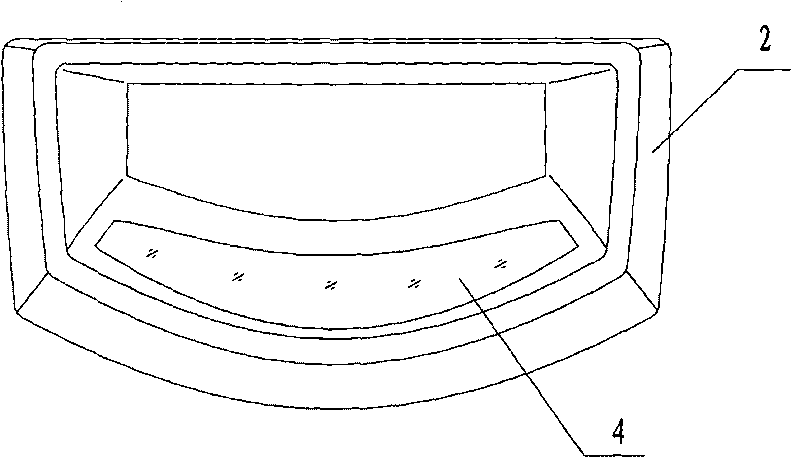

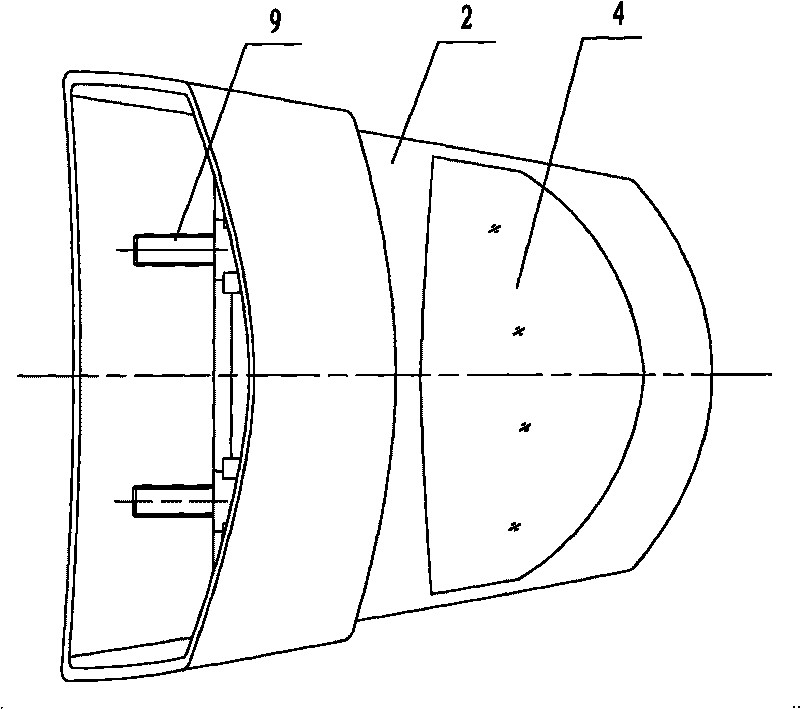

[0013] Such as figure 1 , figure 2 and image 3 As shown, a motorcycle rear license plate light assembly of the present invention has a lamp holder 1, a lamp housing 2 and a bulb 3, the bulb 3 is installed on the lamp holder 1, the lamp housing 2 is connected with the lamp holder 1, and the lamp housing 2 A transparent white sheet 4 is arranged on the lower side relative to the position of the light bulb 3 . Moreover, the lamp holder 1 is installed in the lamp housing 2, the backlight surface 11 on the lamp holder 1 below the light bulb 3 and the surface of the transparent white sheet on the lamp housing 2 are all slopes relative to the horizontal plane, and the lamp holder 1 is facing the light bulb 3 The reflective surface 12 is perpendicular to the horizontal plane, and the lower edge L1 of the reflective surface 12 is higher than the upper edge L2 of the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com