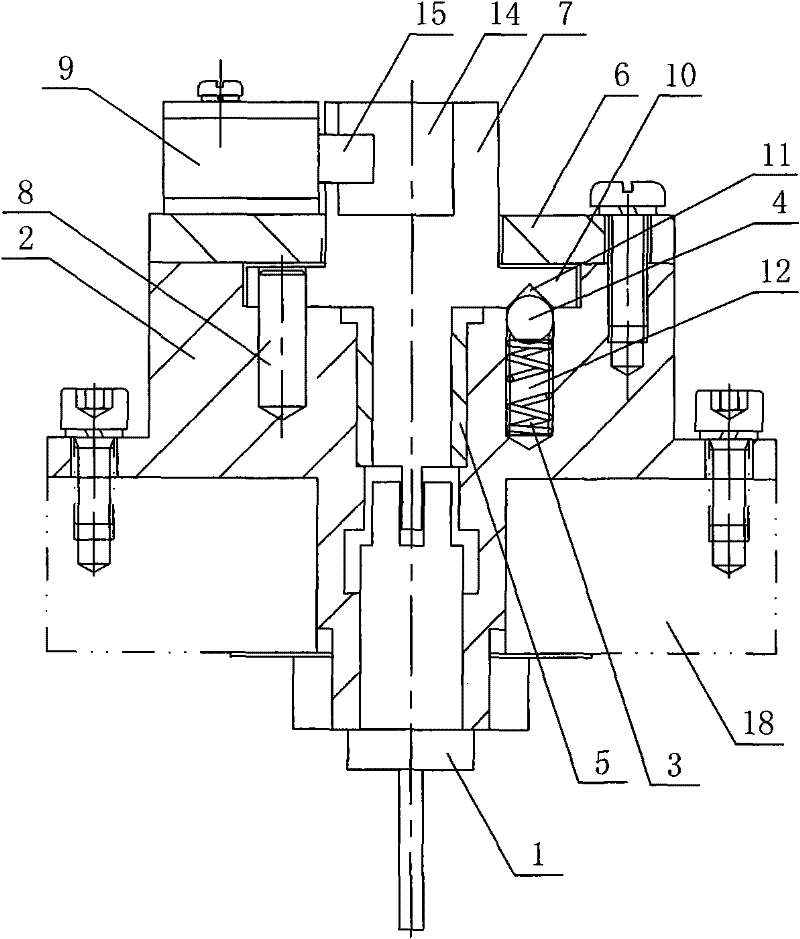

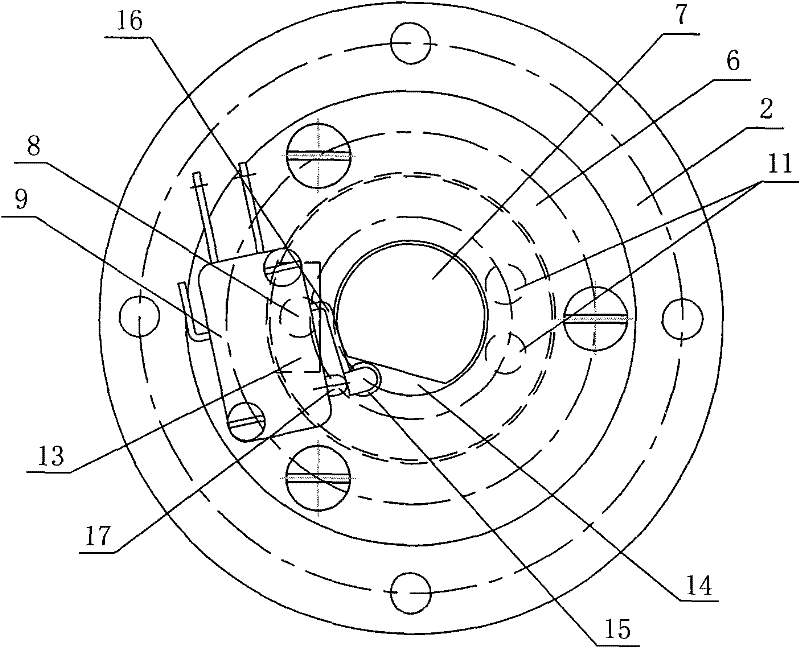

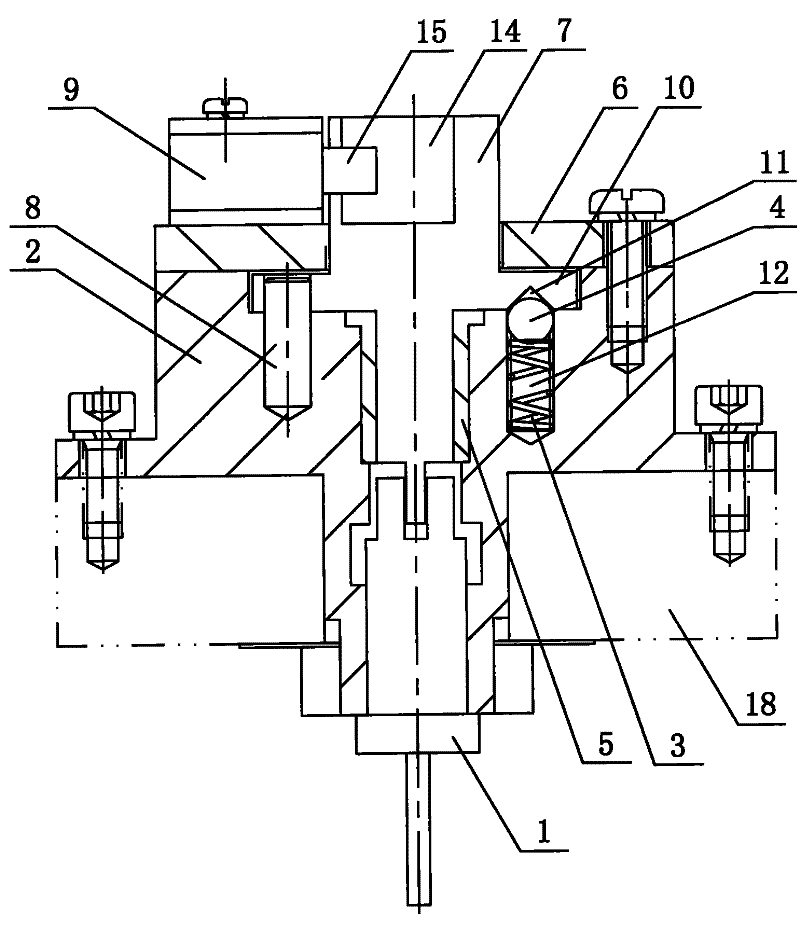

Explosion-proof key switch

A technology of key switch and switch seat, which is applied to electric switches, electrical components, circuits, etc. It can solve the problems of no explosion-proof key switch, complex and bulky structure, and easy failures, etc., and achieves the effects of convenient operation, convenient maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0015] Embodiment 2: The specific structure and working principle of this embodiment are basically the same as those of Embodiment 1. The difference is that the gap between the copper sleeve 5 and the rotating shaft 7 and the switch base 2 is 0.05 mm, and the length of the gap is 15 mm.

Embodiment 3

[0016] Embodiment 3: The specific structure and working principle of this embodiment are basically the same as those of Embodiment 1. The difference is that the gap between the copper sleeve 5 and the rotating shaft 7 and the switch base 2 is 0.15 mm, and the length of the gap is 28 mm.

Embodiment 4

[0017] Embodiment 4: The specific structure and working principle of this embodiment are basically the same as those of Embodiment 1. The difference is that the gap between the copper sleeve 5 and the rotating shaft 7 and the switch base 2 is 0.08 mm, and the length of the gap is 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com