A split plug and method of making the same

A production method and split technology, which is applied in the assembly/disassembly of contact parts, contact parts, electrical components, etc., can solve the problems of waste of resources, low production efficiency, high defective rate of plugs, etc., and improve the problem of power-on and heat generation , improve the service life and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

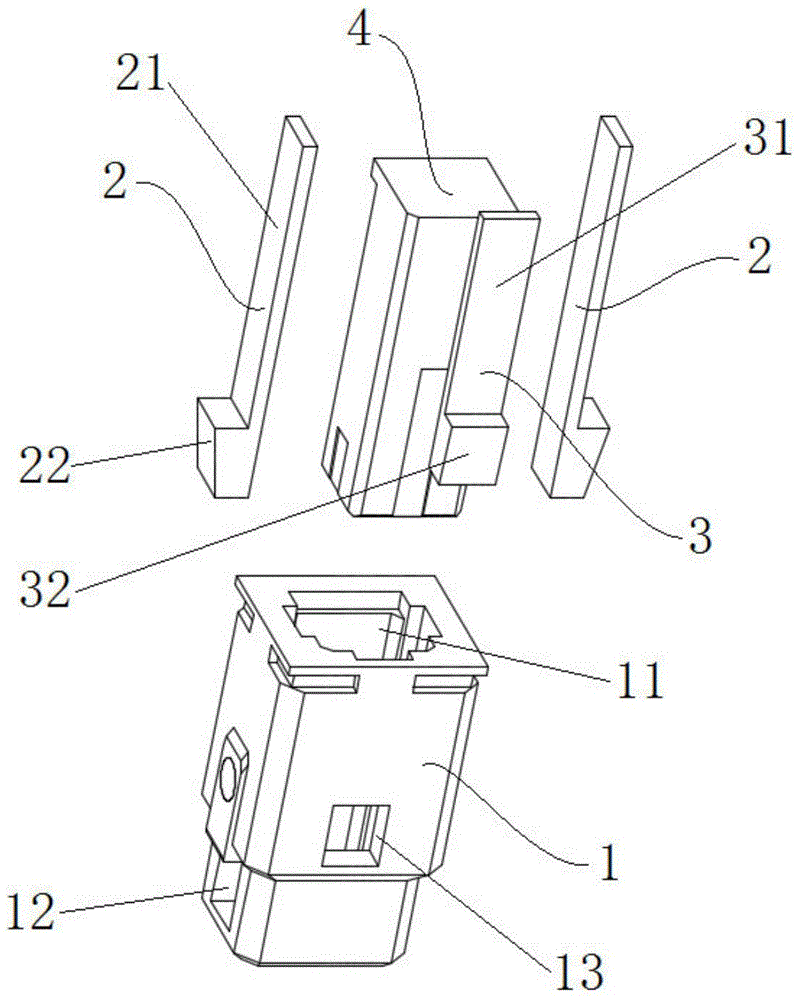

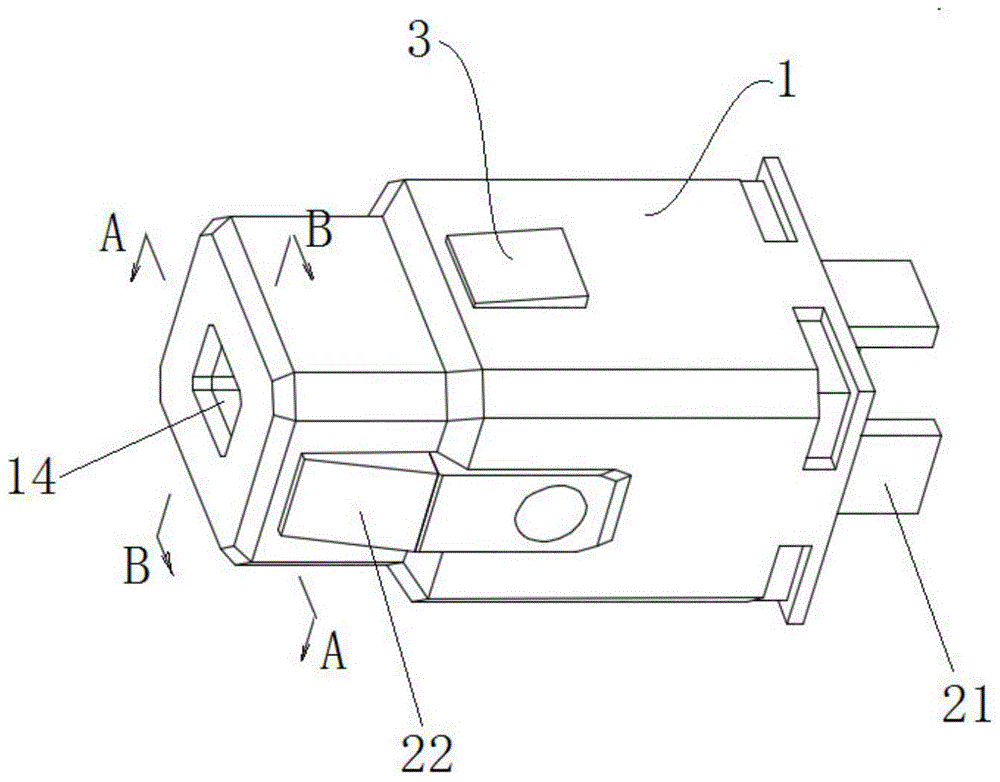

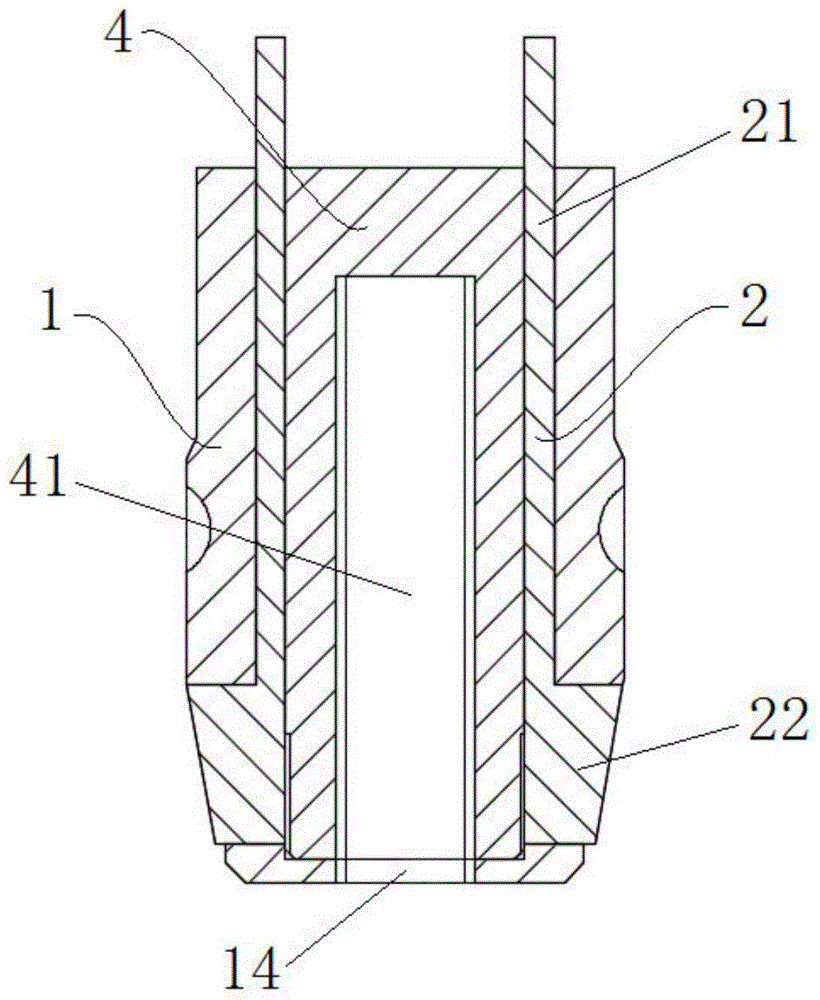

[0038] combine Figure 1 to Figure 4As shown, a split plug of this embodiment includes a plug-in plug housing 1, a power electrode 2, a ground electrode 3 and an electrode fixing plug 4. The plug-in plug housing 1 has an assembly port 11 above it. Cavity, on the side wall of plug plug housing 1, there are power electrode bayonet 12 and ground electrode bayonet 13 respectively communicated with the cavity, and power electrode 2 and ground electrode 3 are assembled in plug plug housing 1 , and make the contacts 22, 32 of the power electrode 2 and the ground electrode 3 snap into the corresponding power electrode bayonet 12 and ground electrode bayonet 13, and the electrode fixing plug 4 is inserted into the plug housing 1 through the assembly port 11 , the power supply electrode 2 and the ground electrode 3 are fixed between the plug housing 1 and the electrode fixing plug 4 . The electrode fixing insert 4 in this embodiment is a cuboid structure, in order to facilitate assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com