A boiler safety explosion-proof device

An explosion-proof device and safe technology, applied in steam boilers, steam boiler accessories, components of steam boilers, etc., can solve problems such as incomplete explosion-proof functions, and achieve the effects of novel conception, strong practicability and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

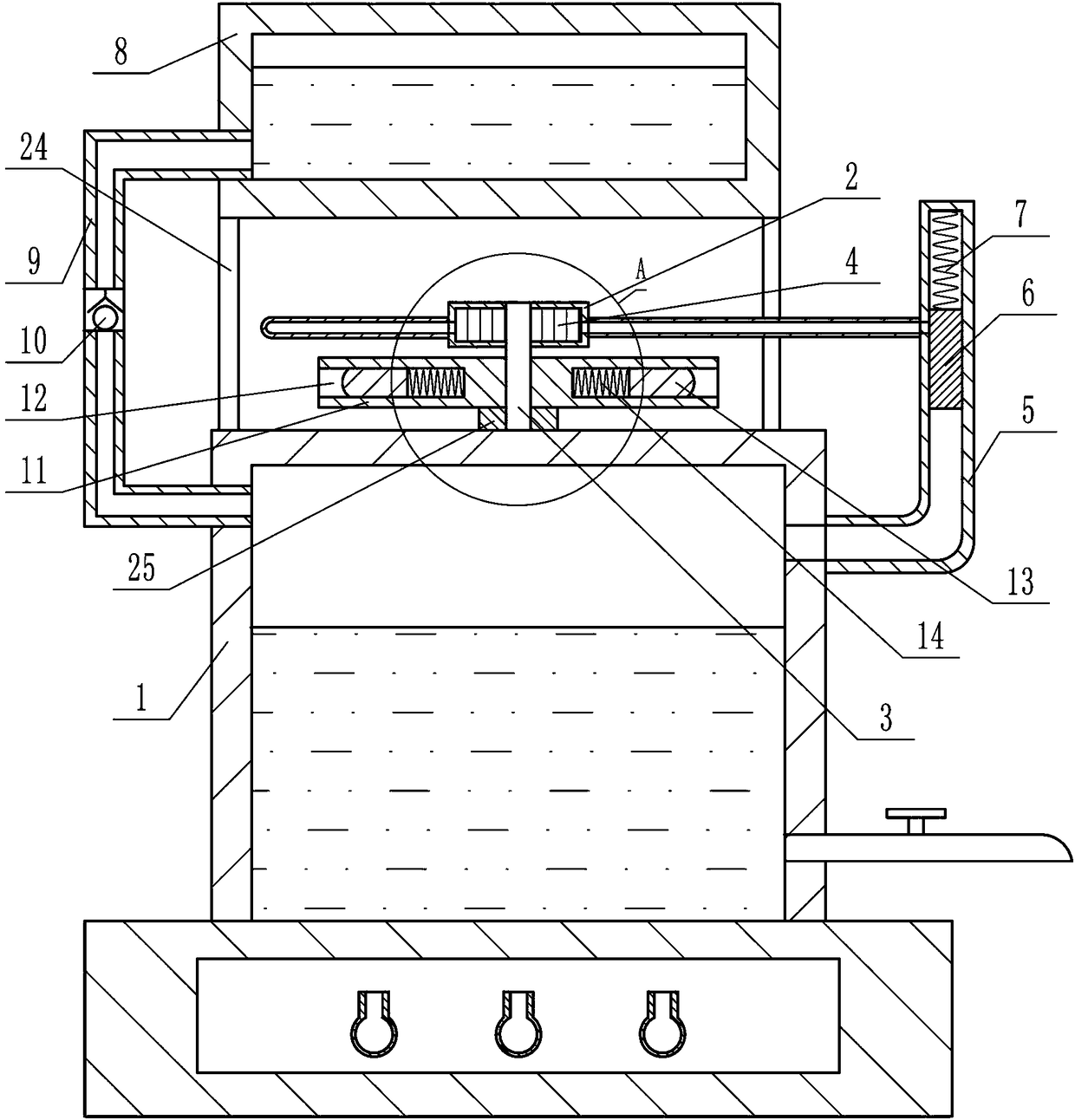

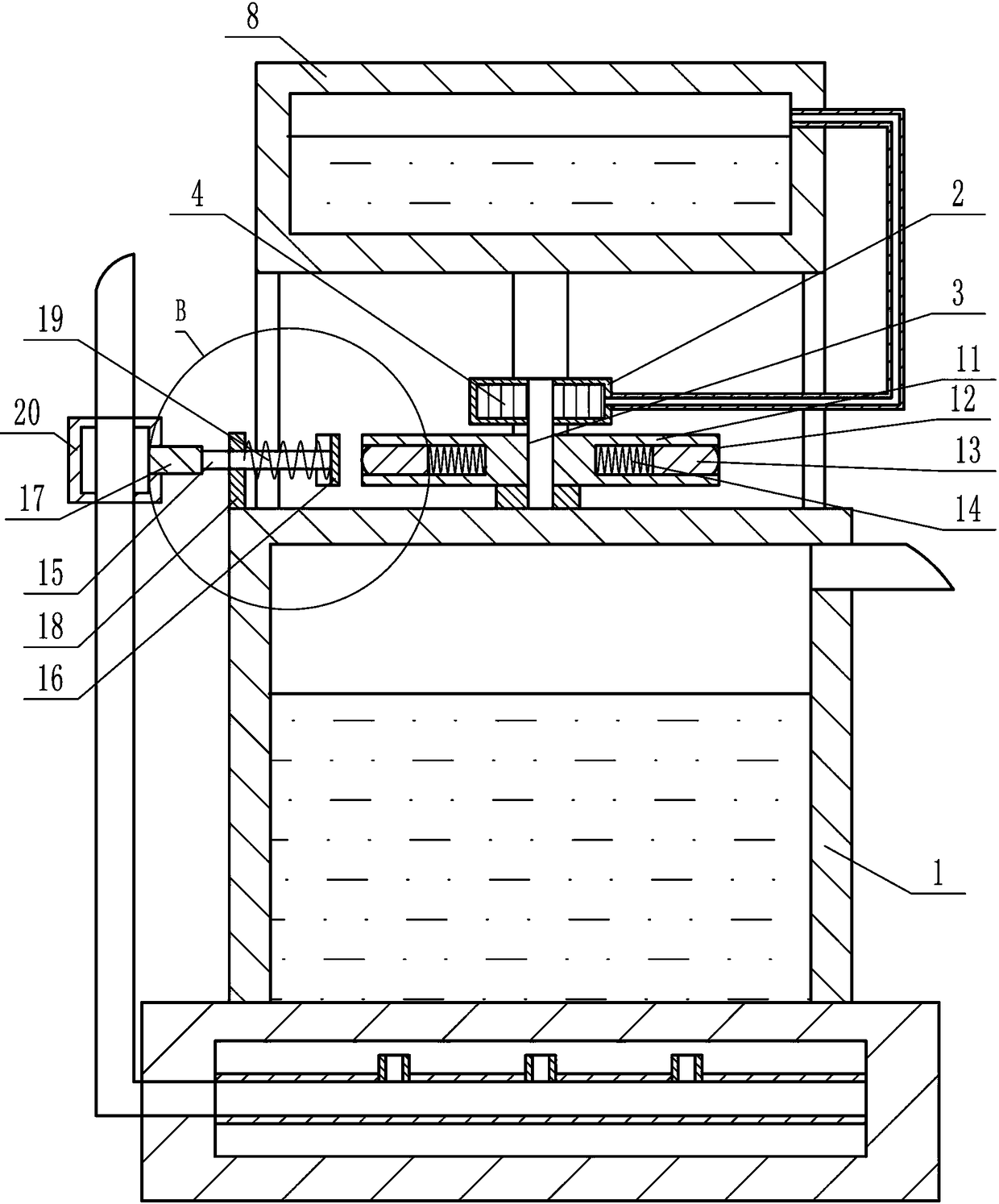

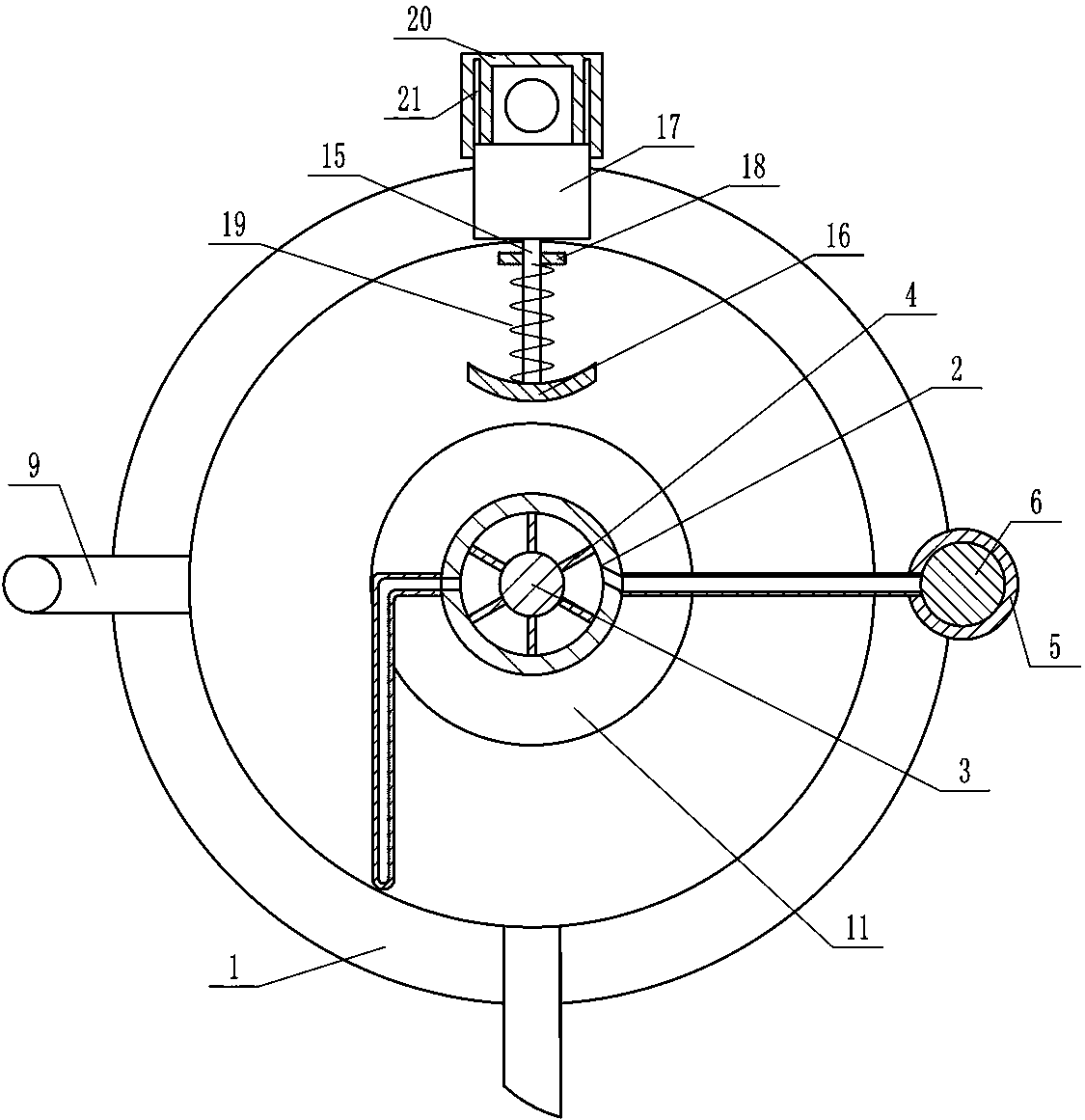

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Depend on Figure 1 to Figure 9 It can be seen that the present invention includes a furnace body 1, a horizontal hollow disc 2 is fixed above the furnace body 1, the hollow disc 2 is a closed structure, a rotating shaft 3 is installed in the center of the hollow disc 2, and the lower end of the rotating shaft 3 is placed on the hollow disc 2, the part of the rotating shaft 3 placed in the cavity of the hollow disc 2 is evenly distributed with a plurality of fan blades 4, the fan blades 4 can drive the rotating shaft 3 to rotate in the cavity of the hollow disc 2, and the right side of the hollow disc 2 The side is provided with the first pipeline 5 that places vertically, and the lower end of the first pipeline 5 communicates with the furnace body 1, and the upper end of the first pipeline 5 is closed, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com