Processing method of ball seal

A processing method and ball sealing technology, applied in metal processing equipment and other directions, can solve the problems of material waste and complex process, and achieve the effect of simplifying the process, omitting cutting steps and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] Heating: According to the material of the forged rod, heat the forged rod to the forgeable temperature according to the conventional process, generally 1050 ° C ~ 1200 ° C;

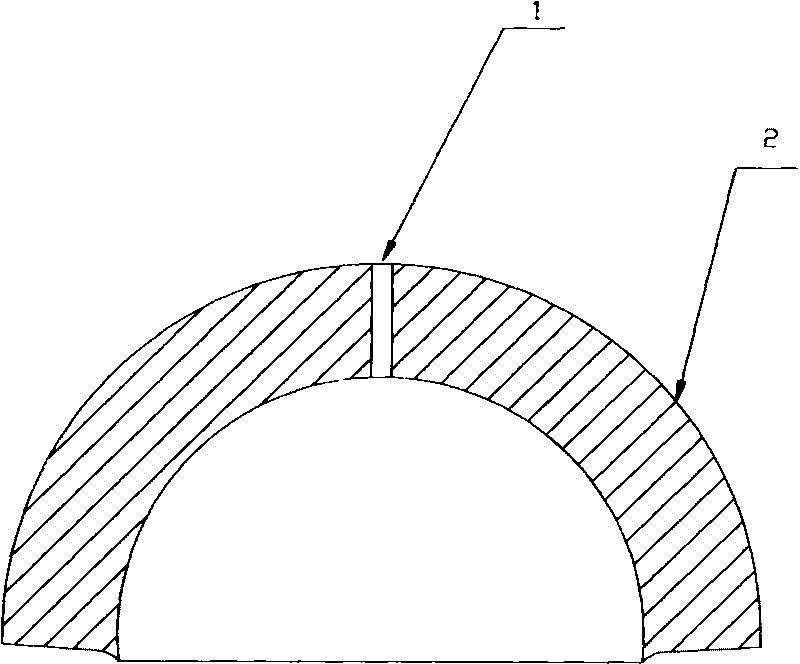

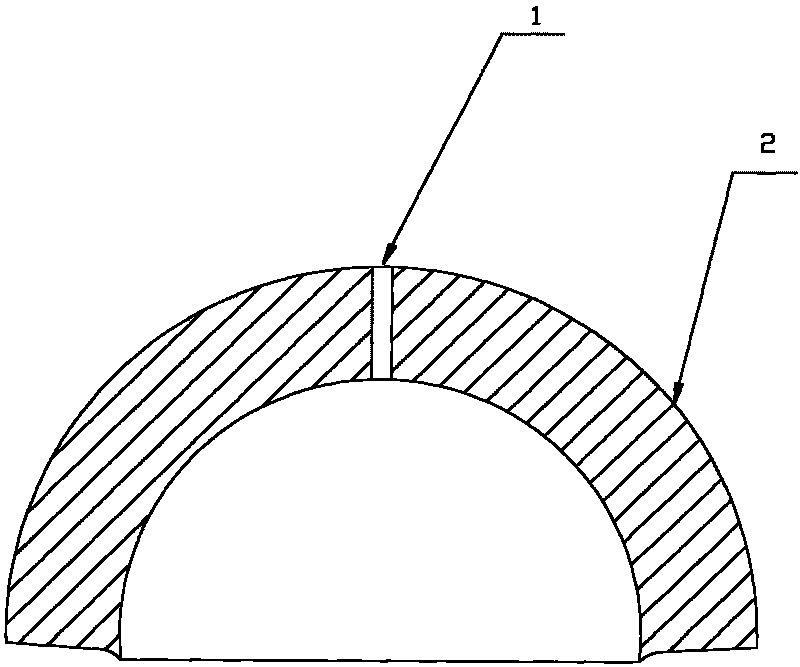

[0011] Die forging: Place the forging rod in the bowl-shaped forging die, align the cylindrical punch attached to the upper part of the forging equipment with the middle position of the bowl-shaped forging die, and then the forging hammer of the forging equipment applies pressure to the punch to form a middle band Bowl-shaped ball seal semi-finished product with punching hole 1;

[0012] Finishing: Finishing according to the needs, such as beveling, chamfering, edging, etc., to form such as figure 1 The ball seal 1 shown is a finished product.

[0013] According to this processing method, if 3.1 tons of finished ball seals are to be prepared, only 3.9 tons of raw materials are needed, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com