Injection mold and method for manufacturing shell by using same

A technology for injection molds and shells, applied in applications, household components, household appliances, etc., can solve the problems of cumbersome processing steps and increase manufacturing costs, and achieve the effect of saving processing time and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

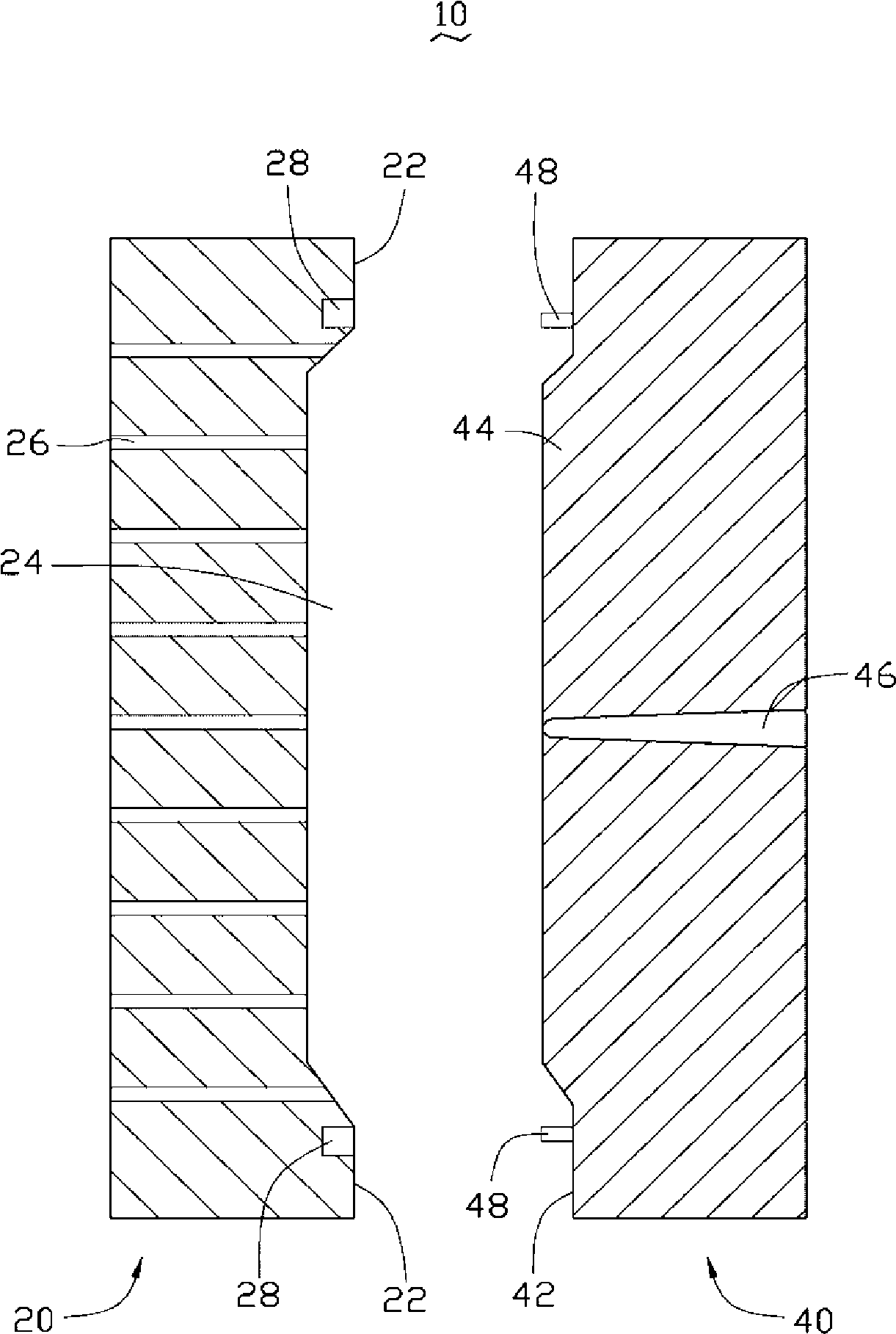

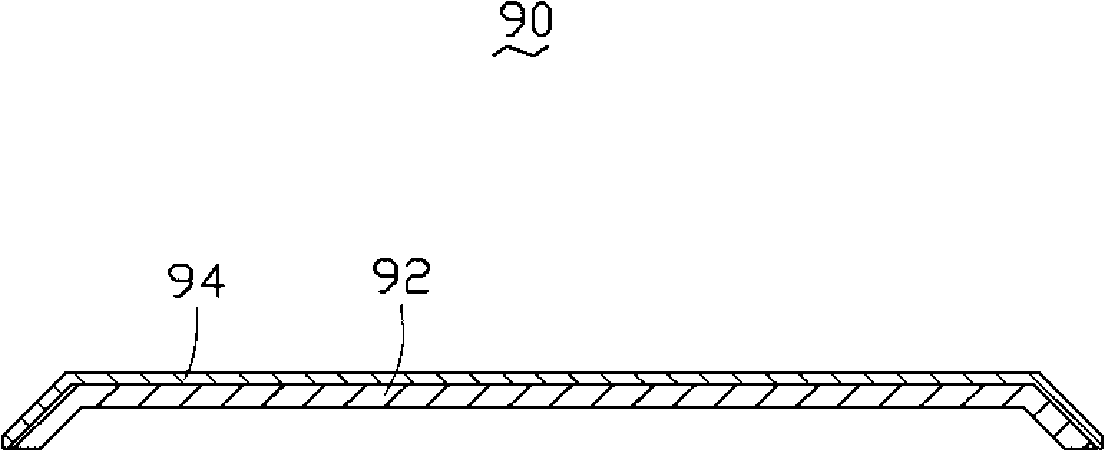

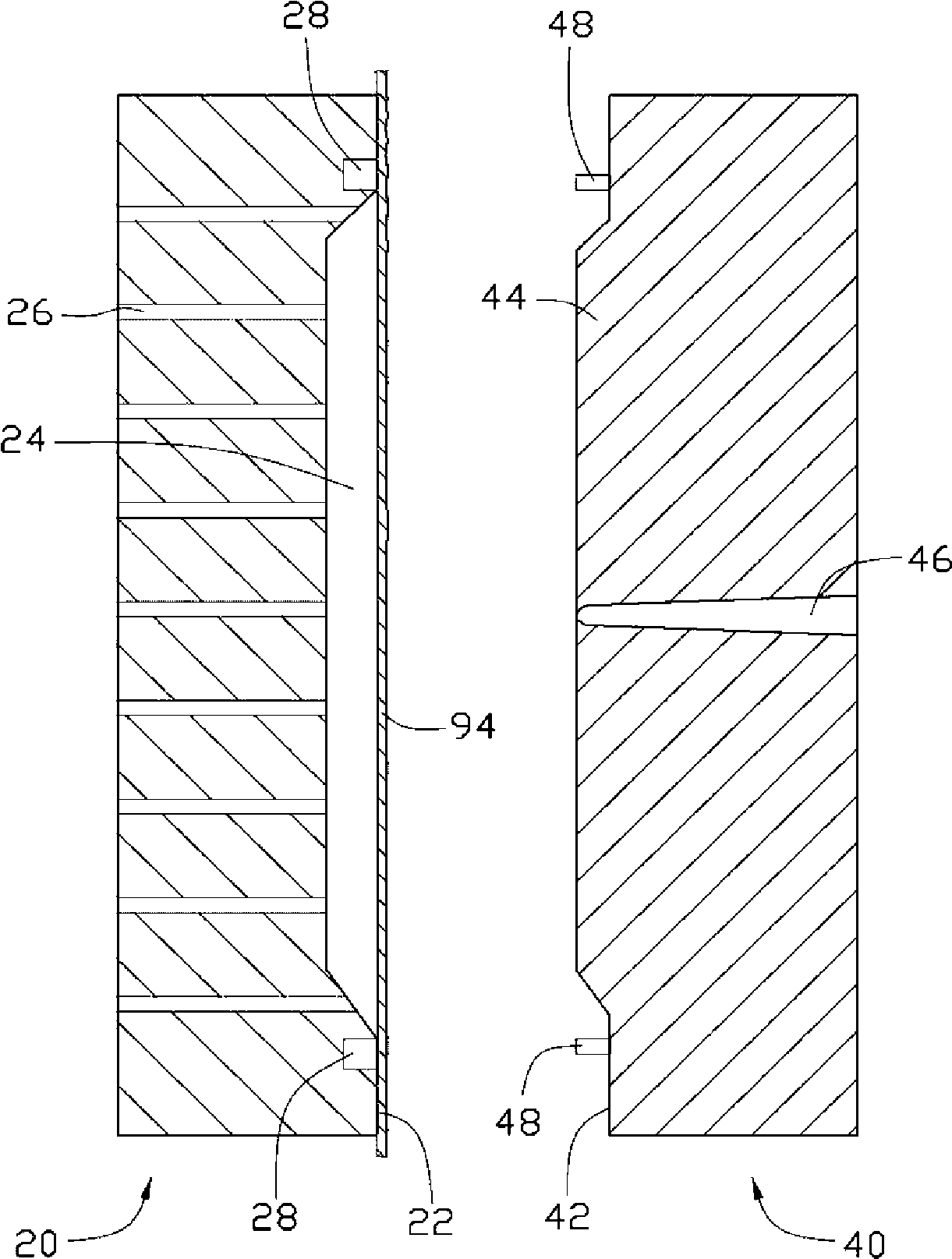

[0020] Please also refer to figure 1 and figure 2 , the injection mold 10 of the preferred embodiment of the present invention is used to manufacture a casing 90 , and the casing 90 includes a base 92 and a soft layer 94 covering the surface of the base 92 .

[0021] The injection mold 10 includes a female mold 20 and a male mold 40 matched with the female mold 20 .

[0022] The female mold 20 includes a joint surface 22 opposite to the male mold 40, a mold cavity 24 is recessed on the joint surface 22, and a plurality of suction ducts 26 are provided on the surface of the mold cavity 24, and the plurality of suction ducts 26 through the master mold 20 . A narrow and long receiving groove 28 is respectively defined on the joint surface 22 adjacent to the two ends of the mold cavity 24 .

[0023] The male mold 40 includes a coupling surface 42 opposite to the female mold 20 , a protrusion 44 protrudes from the coupling surface 42 , and a channel 46 runs through the male mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com