Underreamer with extrusion and wall-expansion functions

A reamer and functional technology, which is applied in drilling equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. and other problems, to achieve the effect of improving the ability of drilling wall protection, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

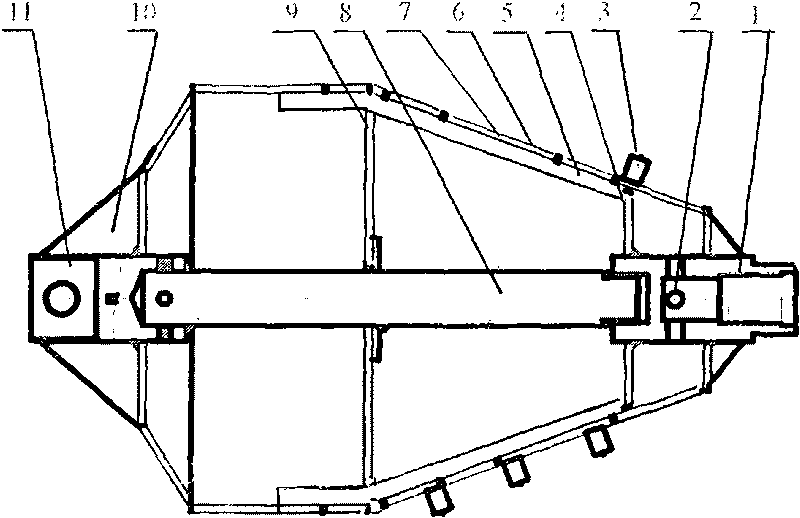

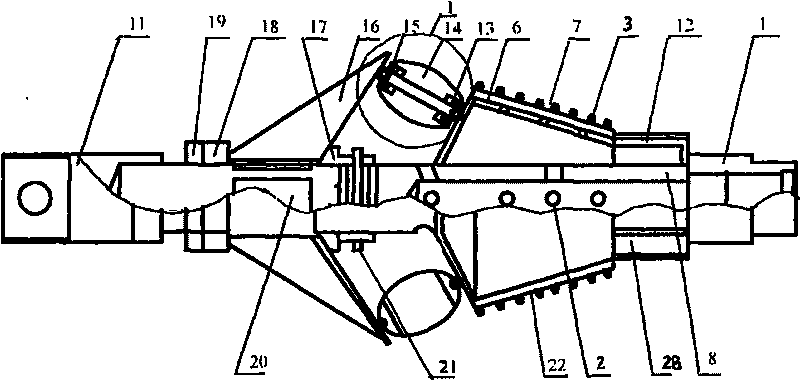

[0018] The main structure of the present invention is that a guide head 12 is added before the reaming body of the reamer, and a set of hole wall extrusion rollers 14 with an adjustable diameter is added after the reaming body.

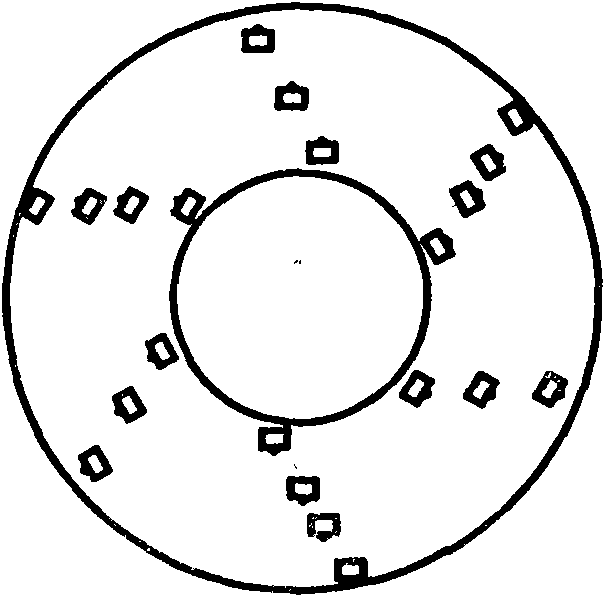

[0019] The present invention is mainly composed of a guide head, a reaming head and a variable diameter hole wall extrusion device (attached figure 2 ), the structure and function of each part are as follows:

[0020] The guide head is mainly composed of a joint 1 and a guide head 12. The right end of the joint 1 has threads for connecting with the drill rod, and the left end is welded or threaded with the guide head and the mandrel 8. A number of wear-resistant ribs 28 are installed on the outer surface of the guide head, the diameter of which is slightly smaller than the diameter of the guide hole or the reaming head, and is used to guide the movement track of the reaming head. The left end of the guide head is welded to the right end of the reamer hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com