Rotary steering tool for well drilling

A rotary steering and tool technology, applied in drilling equipment, directional drilling, drilling automatic control system, etc., can solve the problems of drill string torque, large friction, incomplete wellbore cleaning, slow ROP, etc., and achieve high performance Reliable, simple and inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

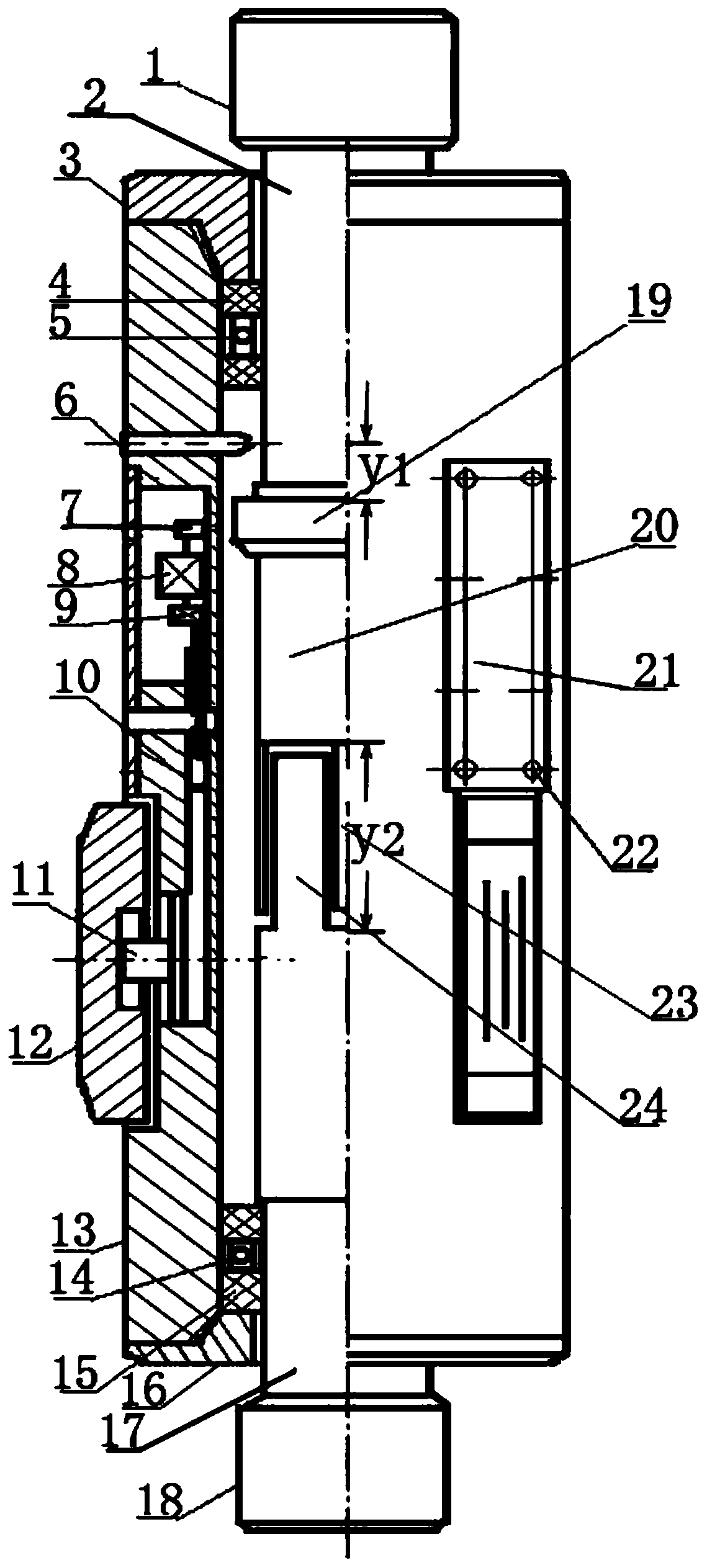

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

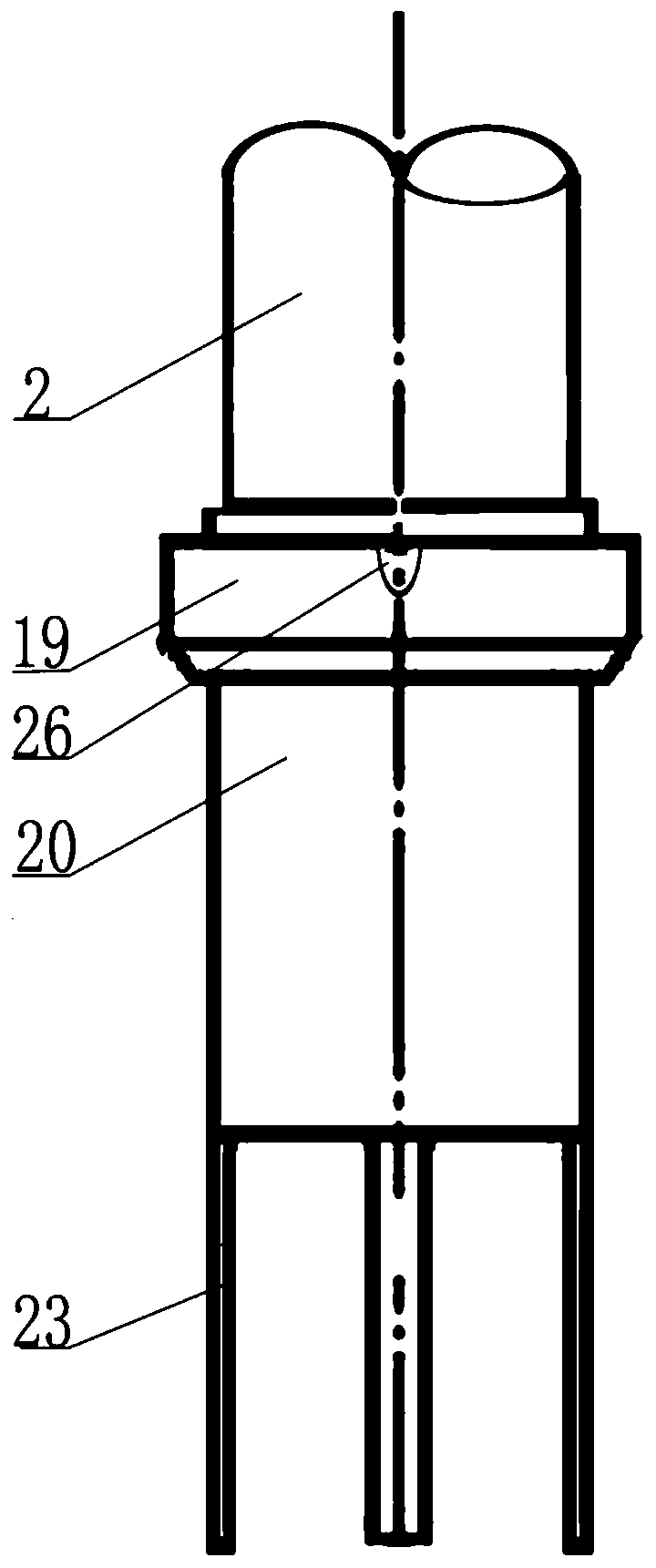

[0031] see figure 1 , figure 2 , image 3 , Figure 4 .

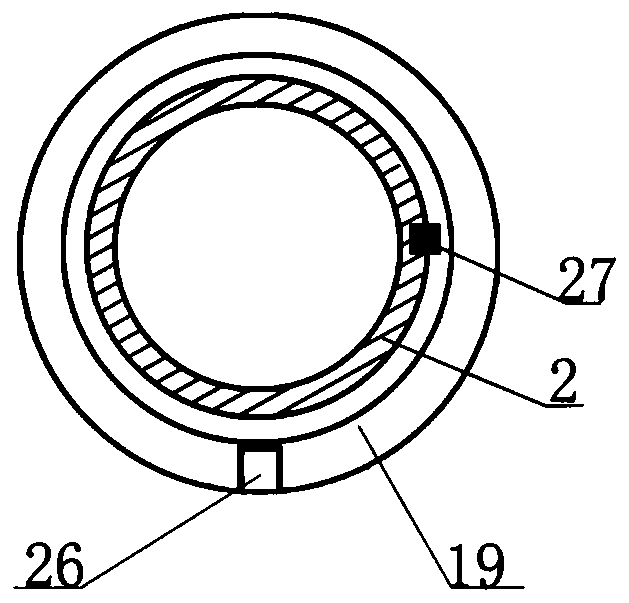

[0032] The tool includes an upper hollow joint 1, a threaded head with an integral structure and a light pipe section 2, the threaded head faces upwards, and is used to connect a drill string; a coupling sleeve 20 is sleeved on the periphery of the light pipe section 2, and the coupling sleeve 20 and the light pipe section 2 are passed through Ying fit, the mating surface is provided with an axial key 27, and the lower end of the light pipe section 2 is an inlay 23.

[0033] The lower hollow joint 18 has a threaded head and a bare pipe section 17 of an integral structure, and the threaded head faces downward for connecting a drill bit. The upper end of the light pipe section 17 is a tooth insert 24, which is engaged with the lower end tooth insert 23 of the light pipe section 2 to transmit torque .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com