Safe alcohol lamp capable of sealing alcohol inside lamp after tipped

An alcohol lamp and alcohol technology, applied in the field of safety alcohol lamps, can solve problems such as burnout, potential safety hazards, poor sealing, etc., and achieve the effects of high safety and reliability, simple and practical sealing, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

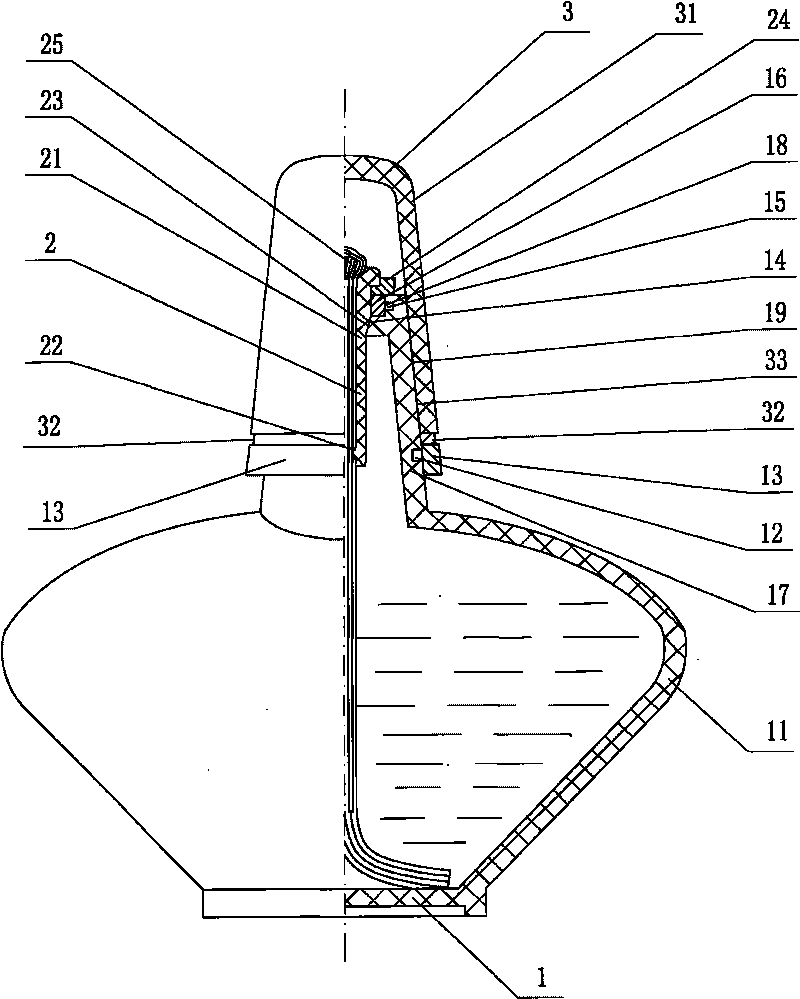

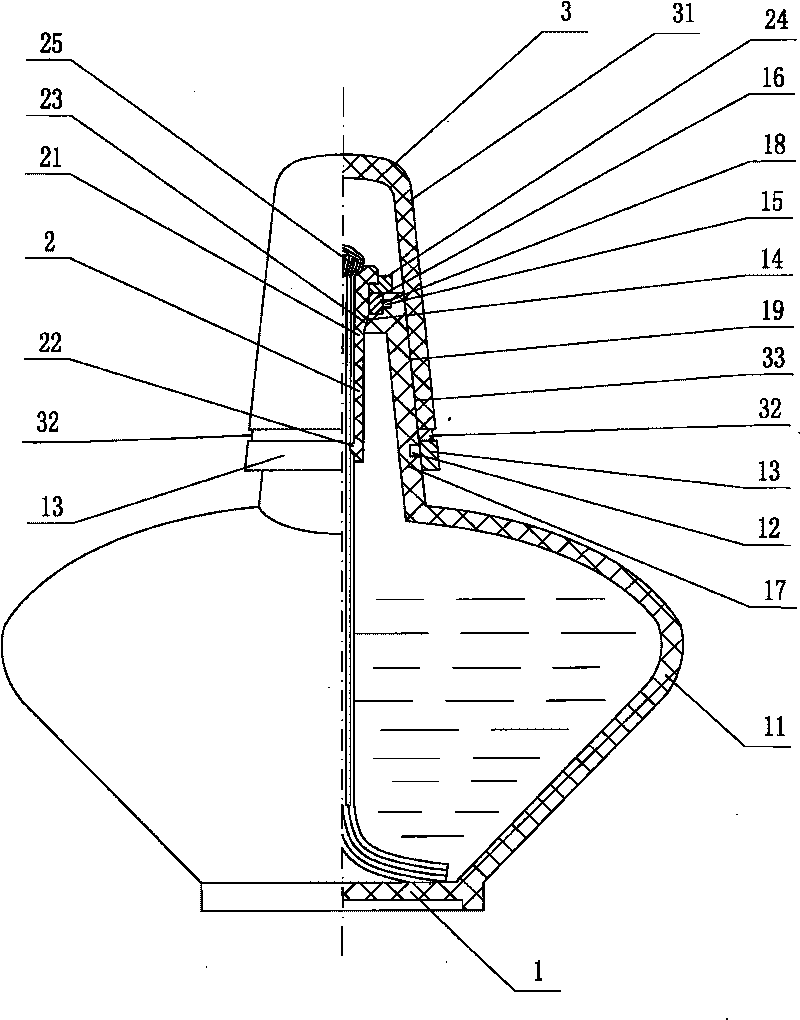

[0025] by attached figure 1 As shown, a safety alcohol lamp in which the alcohol in the lamp is locked after being turned over is composed of a lamp 1, a wick control tube 2, and a lamp cap 3; The bottom glued magnet 13, in order to make conical lamp cap 17 and magnet 13 glue firmly, glue is evenly coated on the bonding surface of the inner surface of magnet 13 and the bottom of conical lamp cap 17, and the bottom of conical lamp cap 17 is provided with annular recess Groove 12, fill the adhesive magnet 13 in the annular groove 12, to increase the bonding strength, glue the magnetic block 16 in the conical hole 18 on the top of the conical lamp cap 17, in order to make the inner wall of the conical hole 18 and the magnetic block 16 gluing Firmly, evenly coat glue on the inner wall of the conical hole 18 and the outer surface of the magnetic block 16, set a groove 15 on the inner wall of the conical hole 18, fill the groove 15 with glue and bond the magnetic block 16 to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com