Packaging structure of soft-package battery

A technology of encapsulating structure and pouch battery, which is applied in the direction of structural parts, secondary battery manufacturing, battery pack parts, etc., can solve the problems of increasing product cost, no space for batteries, and low production efficiency, so as to improve production efficiency and insulate The effect of simple measures and elimination of hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

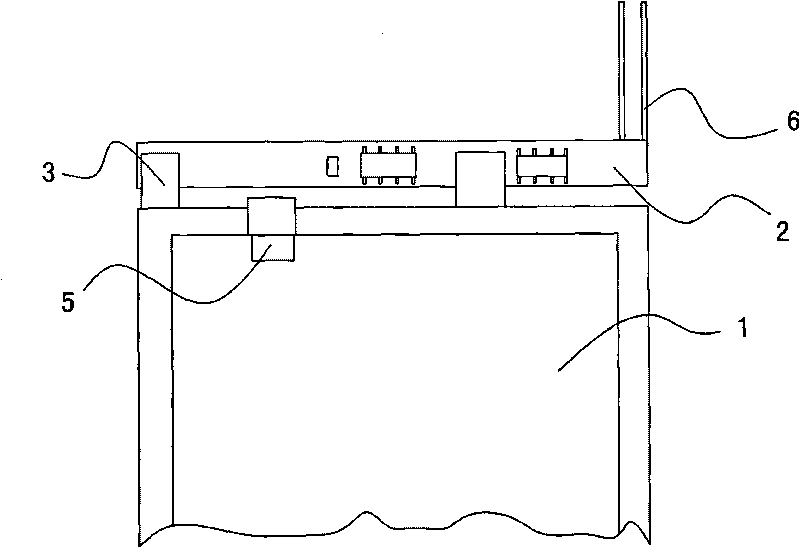

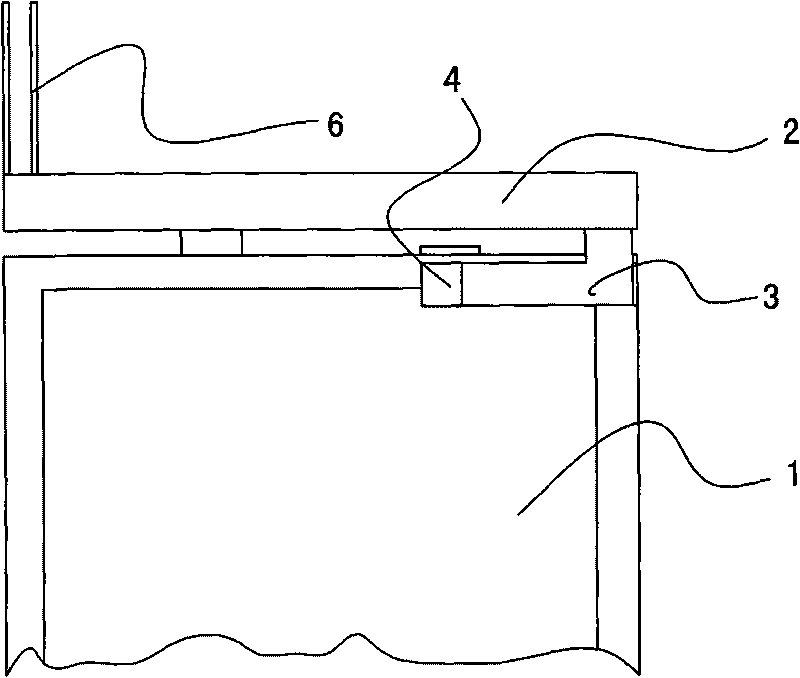

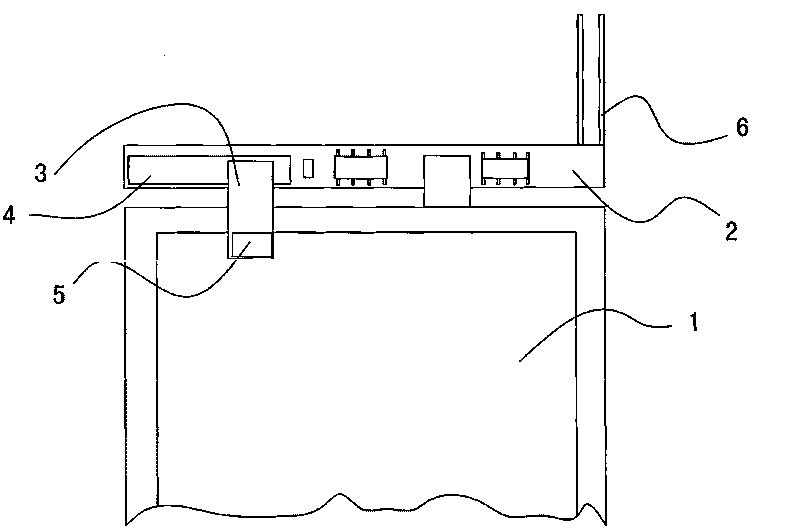

[0016] Please see attached image 3 , the pouch battery in the present invention includes a battery cell 1, and the battery cell 1 is provided with a tab 5 for outputting power. This part is the same as that in the prior art. The contact piece 3 is rectangular (or can be "I" shape), one end of the contact piece 3 is welded on the contact piece 3, and the other end is welded on the PTC4. In this embodiment, the PTC4 is directly welded to the protective plate 2 by spot welding. (i.e. the PCB board), that is, the protection board 2 is connected to the battery cell 1 through the contact plate 3, and the protection board 2 is connected with two wires 6 for battery power output.

[0017] In this embodiment, the protective plate 2 is arranged on the sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap