Food cooking machine

A technology for a food processor and a host, which is applied in the field of food processors, can solve the problems of general noise reduction and vibration reduction, complicated assembly, etc., and achieve the effects of reducing vibration and friction, reducing noise, and reducing coaxiality errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

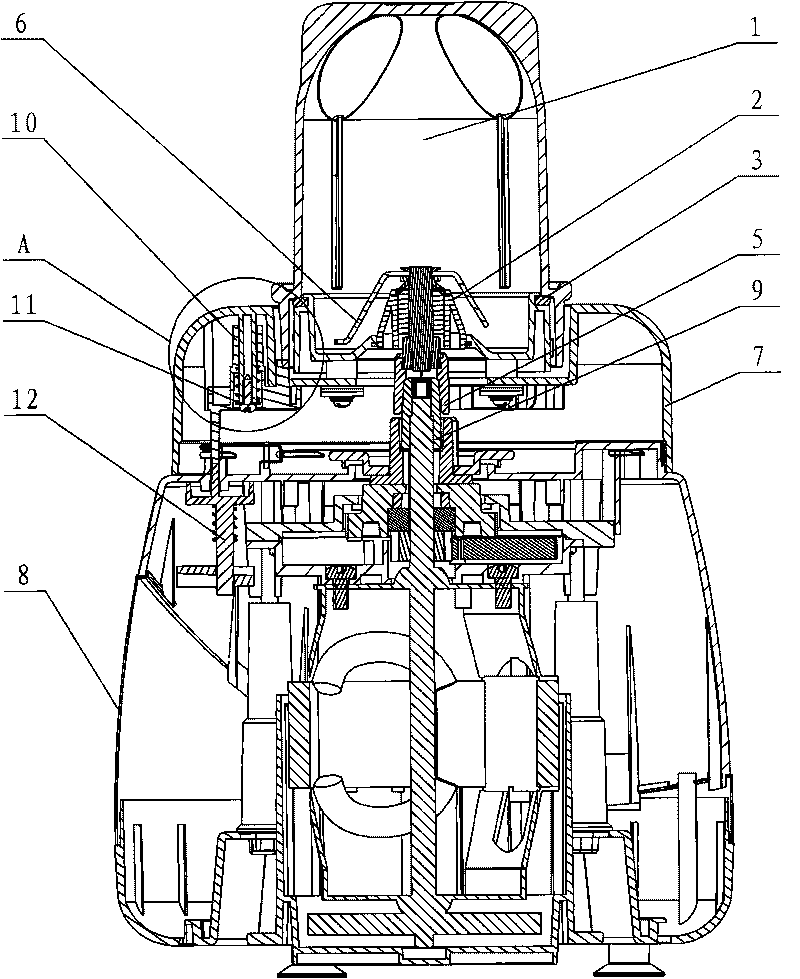

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

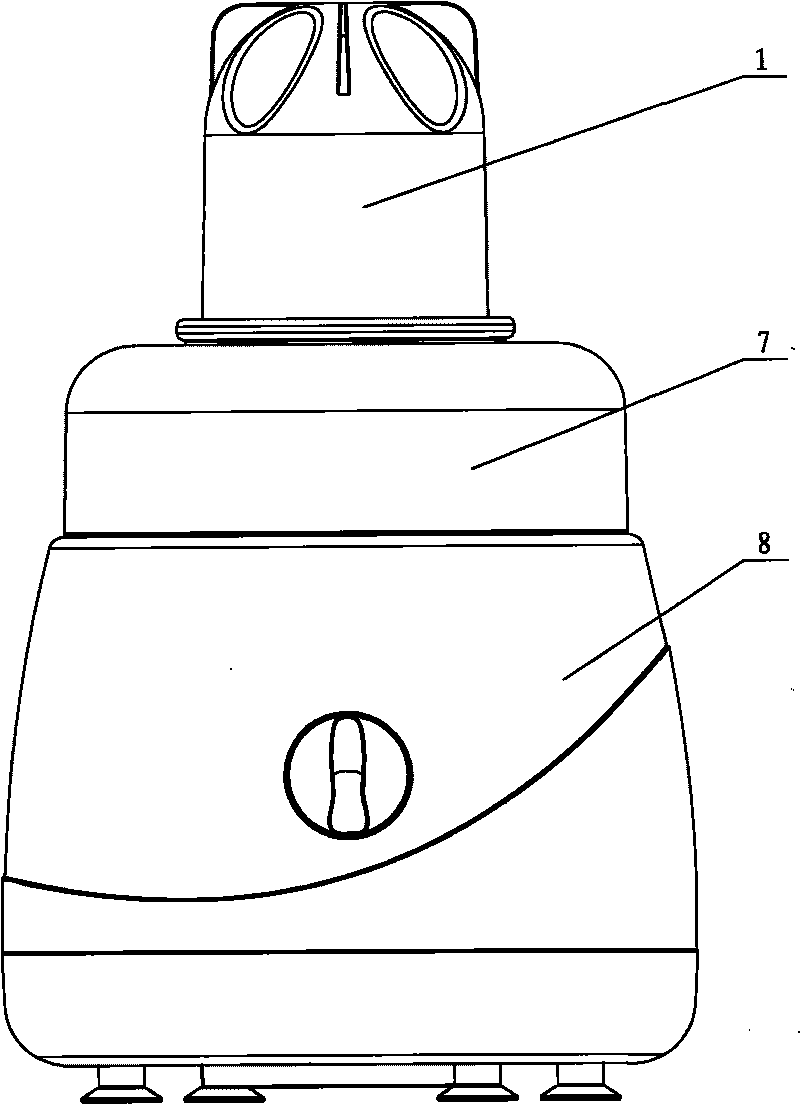

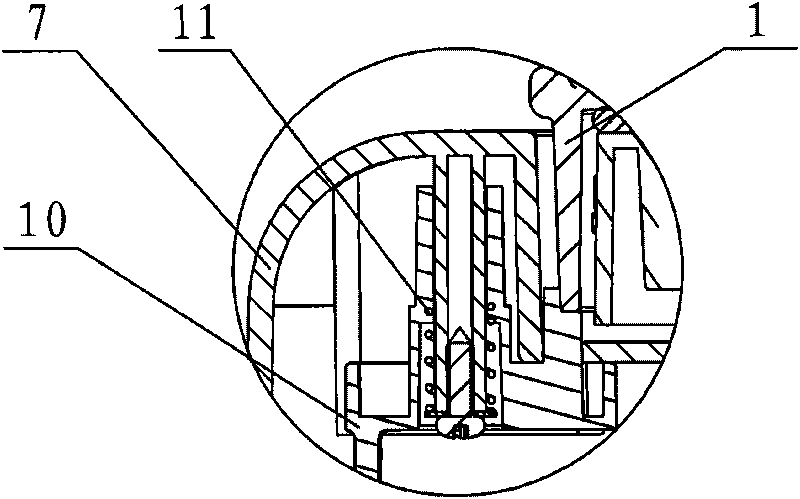

[0018] see Figure 1-Figure 5 , the food cooking machine includes a host 8 and a cup holder 7, a knife holder 2 is arranged in the cup holder, and a shockproof pad 4 is arranged at the connection between the cup holder 7 and the knife holder 2, and the shockproof pad is cylindrical, and the shockproof pad 4 and the knife holder 2 mounting post sockets. The cup holder 7 and the cutter holder 2 are fixed by screws. The knife holder 2 and the cup holder 7 can move freely, and the sealing ring 4 is arranged between the mixing cup 1 and the knife holder 2, and the sealing ring is socketed with the knife holder 2, and the mixing cup 1 and the knife holder 2 are fixed by snap fit , the transmission rod 10 is arranged in the cup holder 7, and the switch connecting rod 12 is arranged at the corresponding position of the main engine 8, and a certain gap is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com