Lower engine hood tool for car painting

A hood and painting technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of poor coating quality at the contact point, deformation of the hood of the body, affecting the quality of the car, and improve the life of the car. , the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

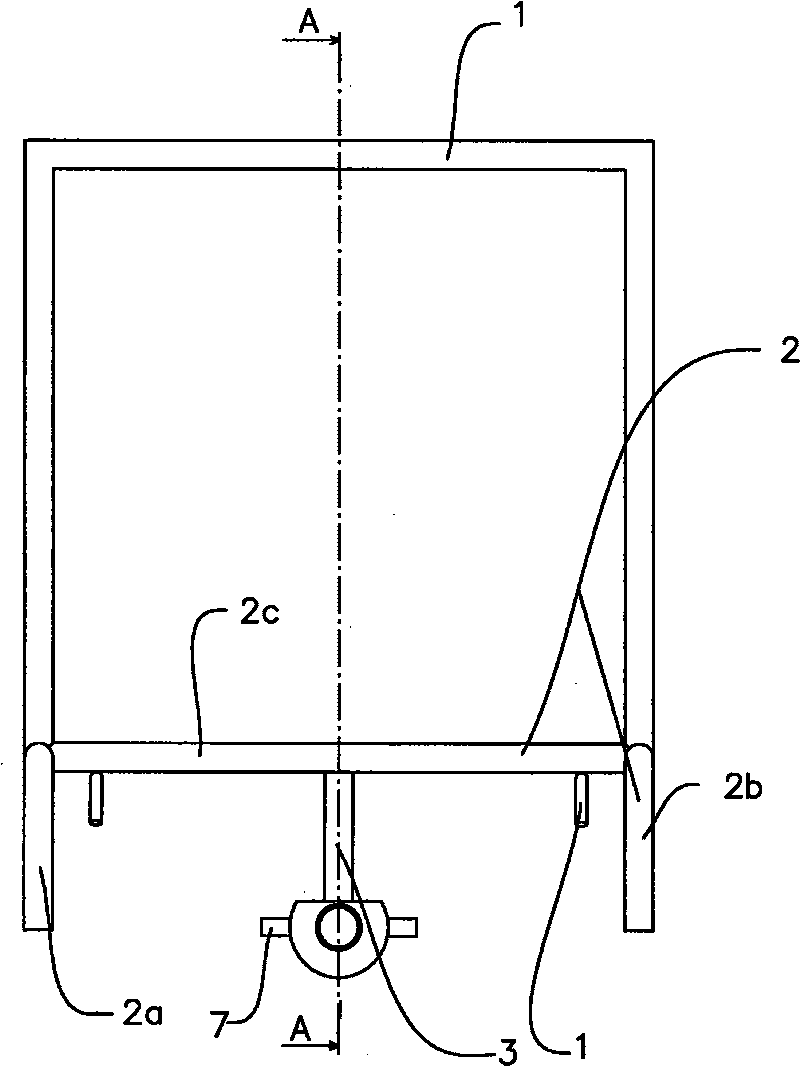

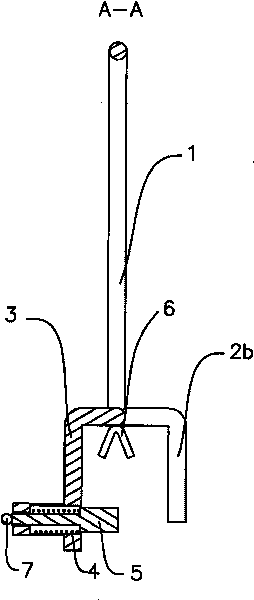

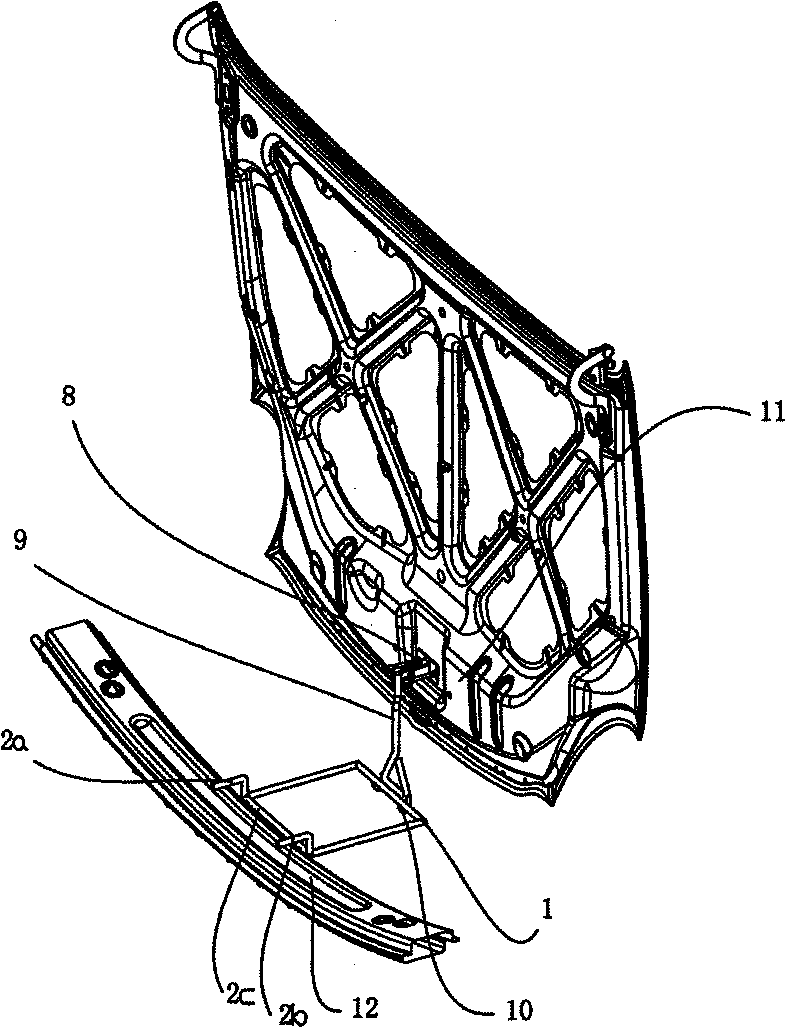

[0017] See Figure 1 ~ Figure 4 : a car painting shown under the hood tooling is composed of a door-shaped support frame 1 and a mounting frame 2 connected to the lower end of the support frame 1, and the two ends of the mounting frame 2 are left and right supports 2a, 2b , a support beam 2c is straddled on the left and right supports 2a, 2b, and a reverse "Z"-shaped middle support 3 is arranged in the middle of the support beam 2c. The upper end of the middle support 3 is fixed on the support beam 2c, and the lower end The transverse part is axially provided with a stepped hole with a small front and a large rear, and a spring 4 is housed in the stepped hole, and a stepped shaft 5 passing through the spring 4 with a small front and a large rear is provided in the stepped hole. The small-diameter end of the shaft 5 stretches out of the step hole 3a, and one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com