Switching device of cast equipment of concrete bored pile

A technology of bored cast-in-place piles and switchgear, which is applied in construction, sheet pile walls, and foundation structure engineering, and can solve problems such as reducing the strength and hardness of concrete bored piles, affecting the quality and safety of pile foundations, and eliminating Effects of broken pile accidents, quality and safety assurance, and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

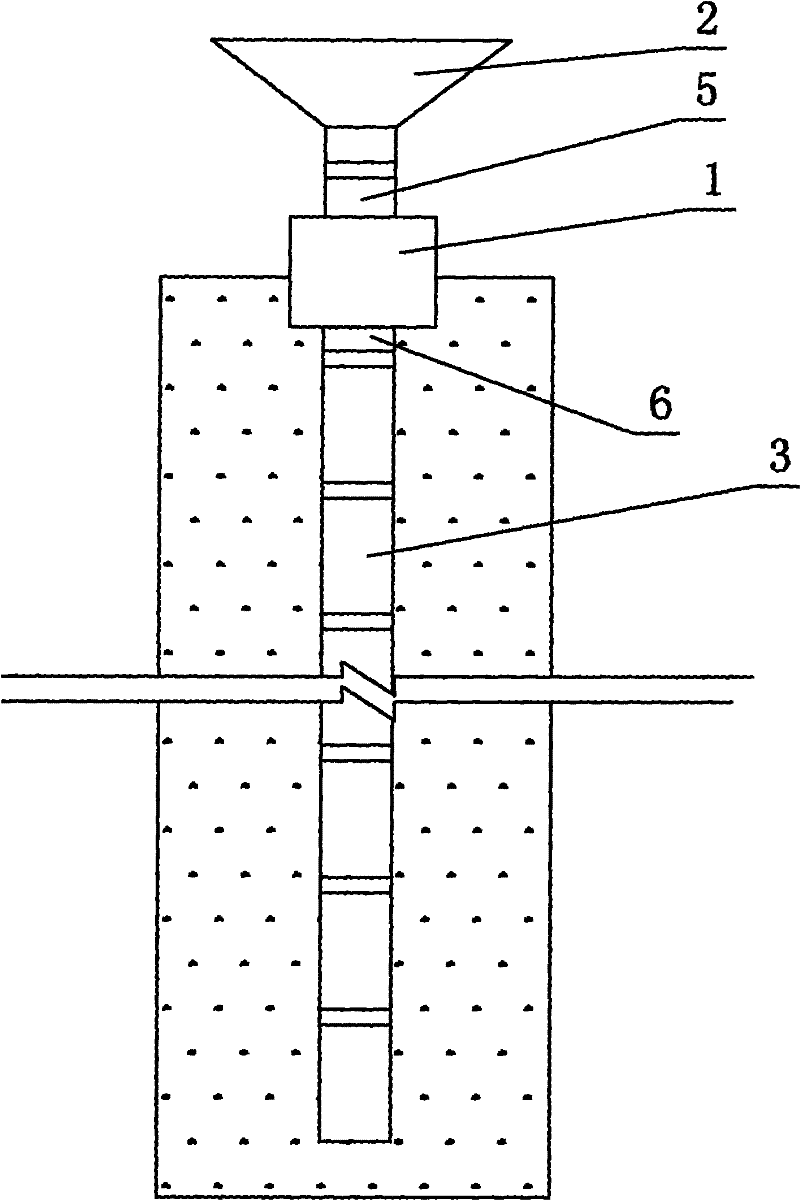

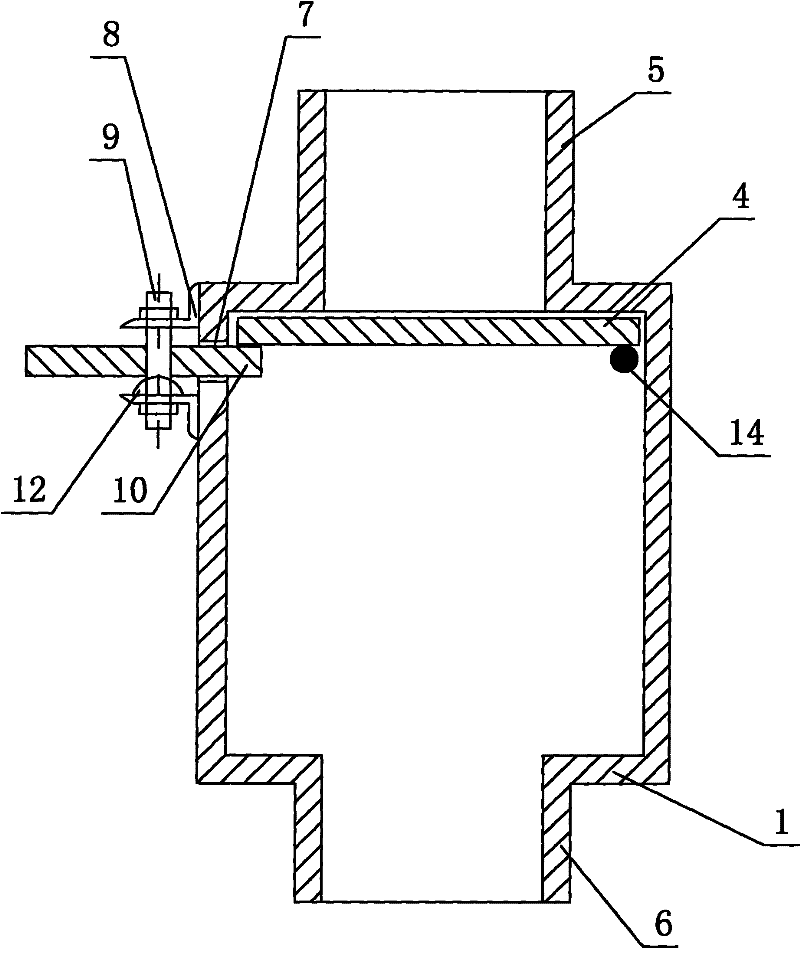

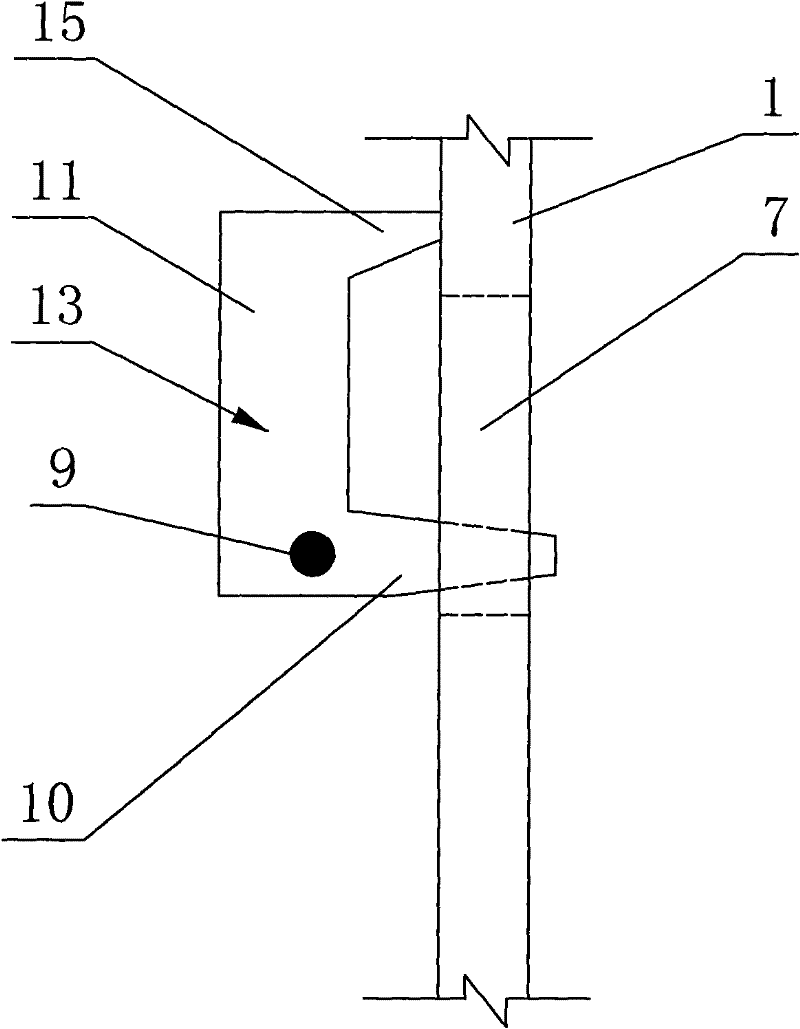

[0037] Such as figure 1 , figure 2 , image 3Shown, the switchgear of the pouring equipment of the concrete bored cast-in-place pile of the present invention, it comprises a hollow steel box body 1. The upper end of the steel box 1 communicates with the lower end of the hopper 2, that is, the upper end plate of the steel box 1 is provided with a communication port, and an upper butt joint 5 is welded on the communication port. The connecting pipe 5 communicates with the hopper 2 . The lower end of the steel box 1 communicates with the top of the main conduit 3, that is, the lower end plate of the steel box 1 is provided with a communication port, and a butt joint 6 is welded on the communication port. The connecting pipe 6 communicates with the main conduit 3 . A partition plate 4 whose shape and area match the cross section in the steel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap