Fire water monitor head for performing direct current spray conversion by adopting hydraulic drive

A technology of hydraulic drive and water cannon, applied in fire rescue and other directions, can solve the problems of small scope of application of the conversion mechanism, jamming, increase in the volume of the gun head, etc., and achieve the effect of eliminating the complexity of the mechanism and the large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

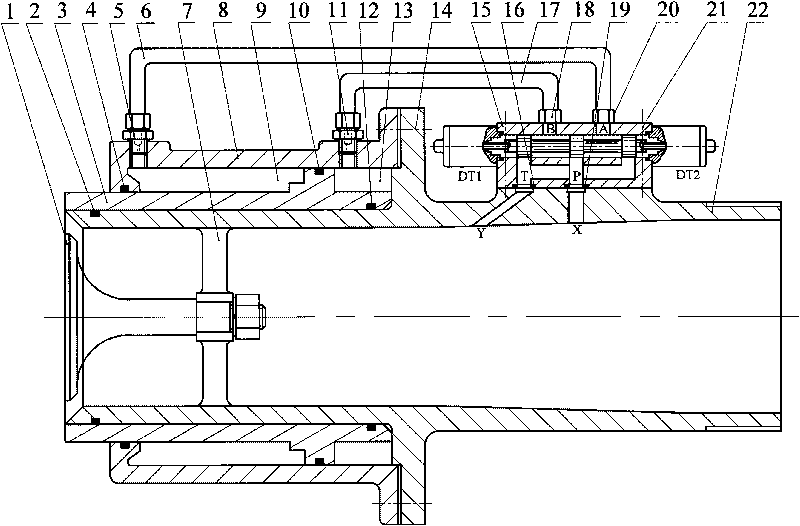

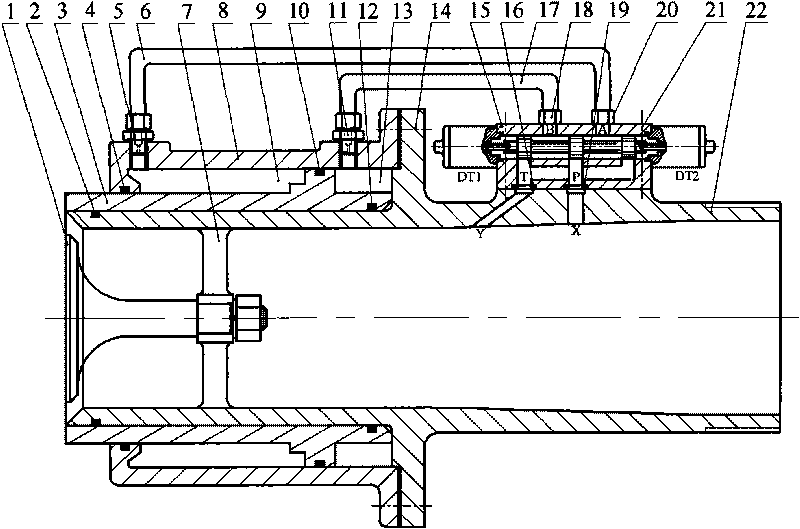

[0012] as attached figure 1 Shown, the present invention comprises nozzle core 1, sealing ring 2,4,10,12, nozzle 3, pipe joint I 5, water delivery hose I 6, nozzle core frame 7, cylinder body 8, left water pressure chamber 9, Pipe joint II 11, right water pressure chamber 13, fastening bolt 14, three-position four-way pure water electromagnetic reversing valve 15, sealing gaskets 16, 19, water hose II 17, pipe joint III18, pipe joint IV 20, Countersunk screw 21, nozzle housing 22.

[0013] The nozzle core 1 is fixed on the nozzle core frame 7 by a washer and a lock nut; the inner wall of the nozzle 3 forms a clearance fit with the outer wall of the nozzle housing 22, and the outer wall of the nozzle 3 forms a clearance fit with the inner wall of the cylinder body 8, and the nozzle 3 can Slide back and forth along the axial direction of the nozzle housing 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com