Filter paper folding device of clapboard type filter

A folding device and filter technology, applied in the direction of cardboard items, etc., can solve the problems of low production efficiency, waste of filter paper, difficult to guarantee manual operation, etc., and achieve the effects of easy control, high consistency, and neat finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

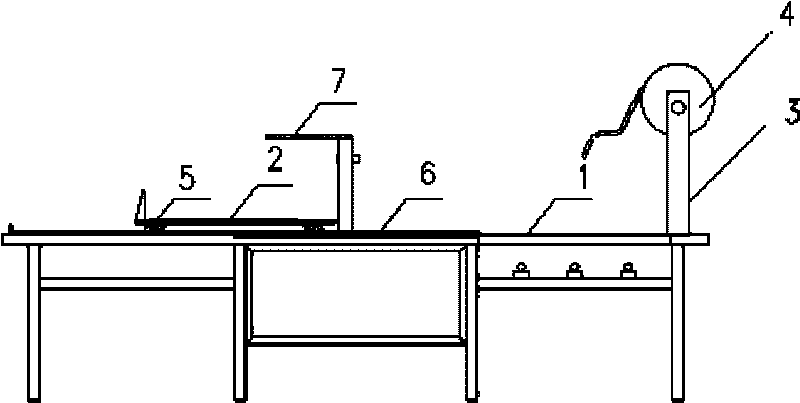

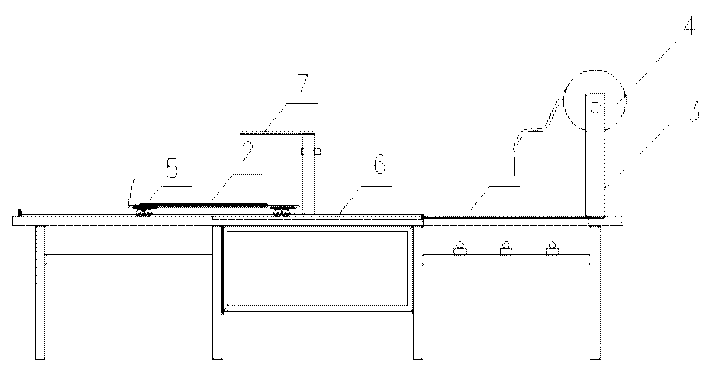

[0008] See the accompanying drawings for details, a filter paper folding device for a clapboard filter, including a workbench 1, a fixed support 3 on the workbench surface 2, and a roller 4 with filter paper supported on the support. The longitudinal axis is a movable workbench top, and parallel rollers 5 are arranged on both sides of the lower surface of the workbench top, and guide rails 6 that are fixed on the worktable and cooperate with the rollers. A height-limiting device is fixed at the opposite end of the workbench to the support, and the height-limiting device 7 is formed of an upper panel and two side panels in the shape of a "bench".

[0009] Operation process: The structure of the separator filter is to set a separator with a corrugated cross-section between the filter papers. During production, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com