Valves

A valve hole and valve seat technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve problems such as mechanism failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

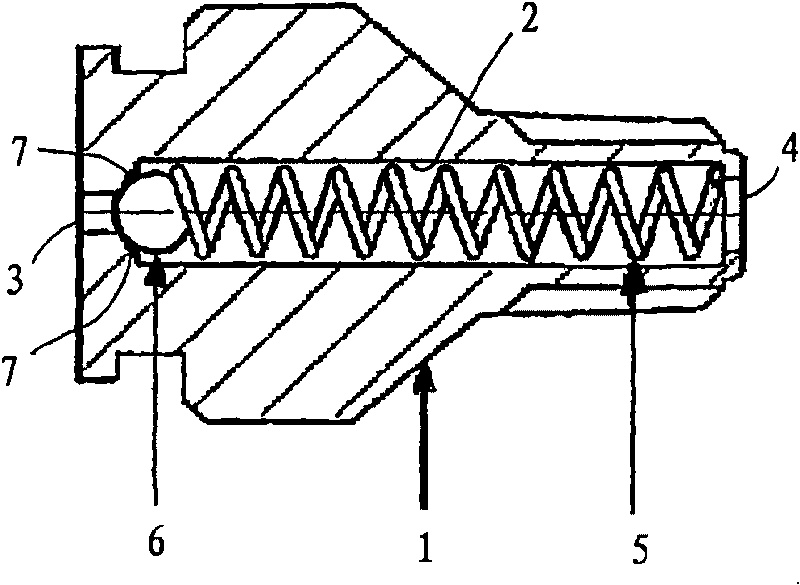

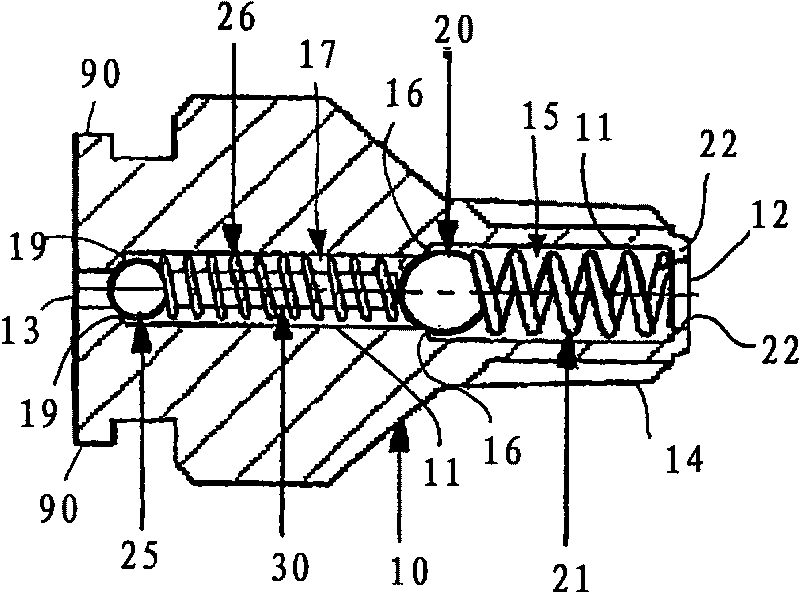

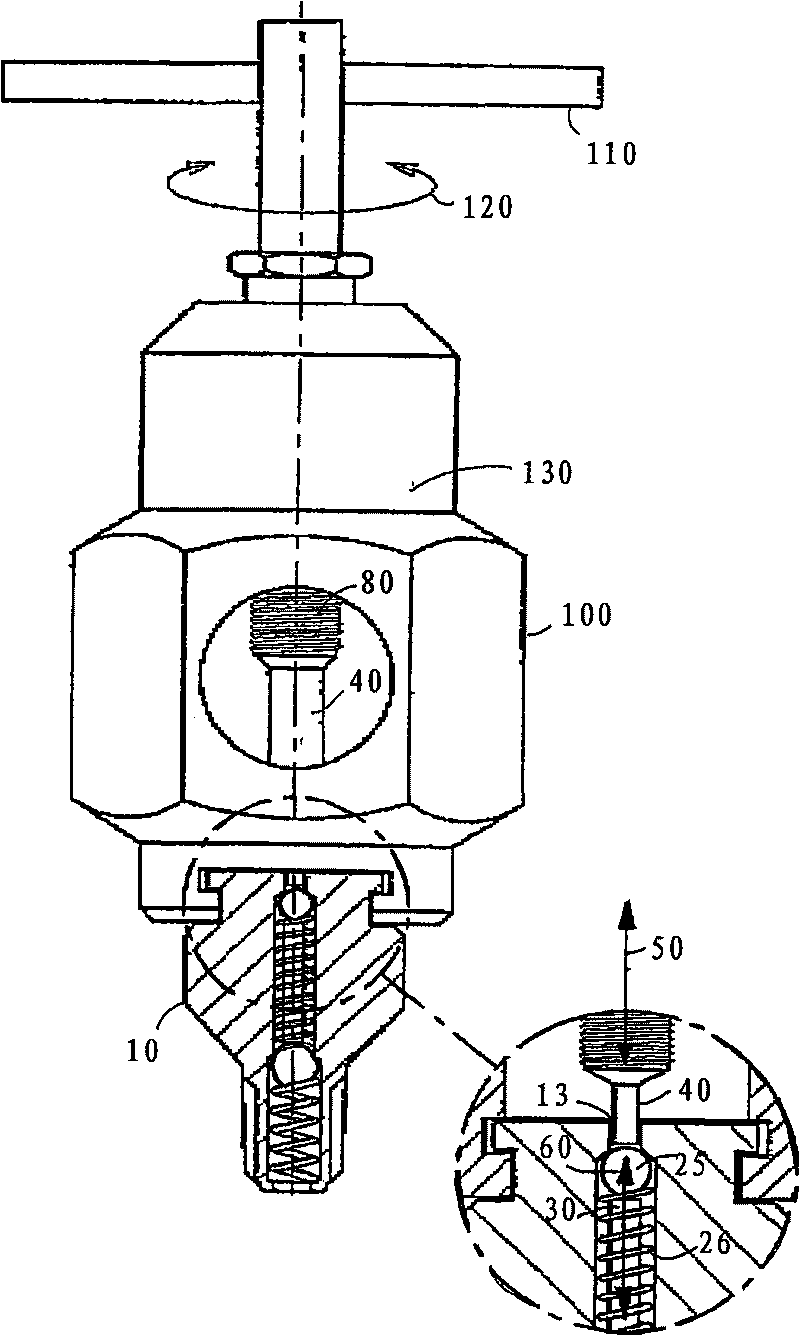

[0044] figure 2 A cross-sectional view of a valve according to one embodiment of the invention is shown. The valve comprises a valve body 10 through which a valve bore 11 passes from a first valve opening 12 to a second valve opening 13 .

[0045] The outer surface of the valve body adjacent to and surrounding the first valve opening defines a nozzle 14 extending in a direction parallel to the axis of the valve bore. The outer surface of the nozzle is threaded to enable the nozzle to be coupled into a correspondingly threaded aperture in a container or cavity wall to couple and form a sealing fit with the valve body to the container or cavity. The end surface of the nozzle is shaped to define a first valve opening which, in use, is used to allow a substance (eg, a pressurized fluid) to enter the valve from a container or cavity to which the valve is coupled. In the hole, and let the substance (for example, lubricant) to be injected into the container or cavity through the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com