Squeeze-in type wheel load force transducer

A force sensor, wheel weight technology, applied in the direction of measuring force, instruments, measuring devices, etc., can solve the problems of nonlinear error zero point and instability, and achieve the effect of improving nonlinear error and zero point instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

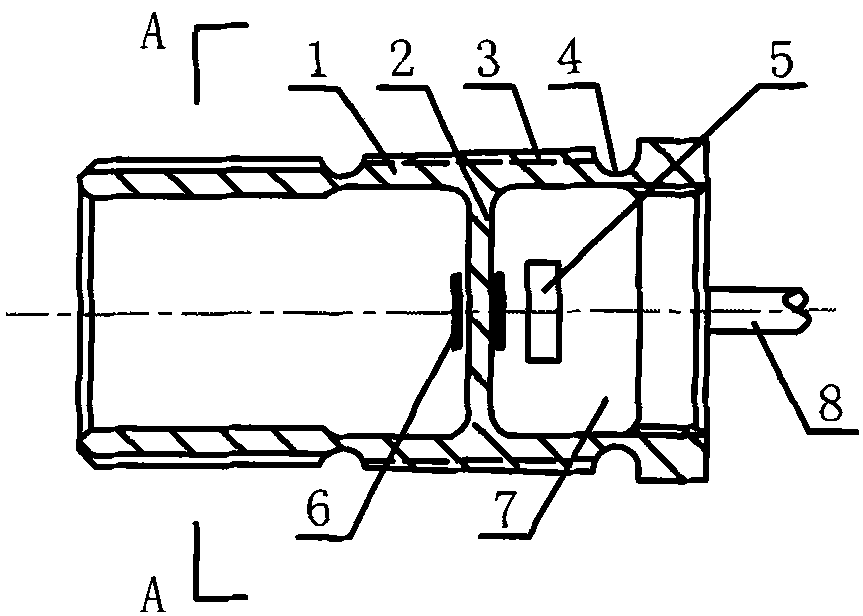

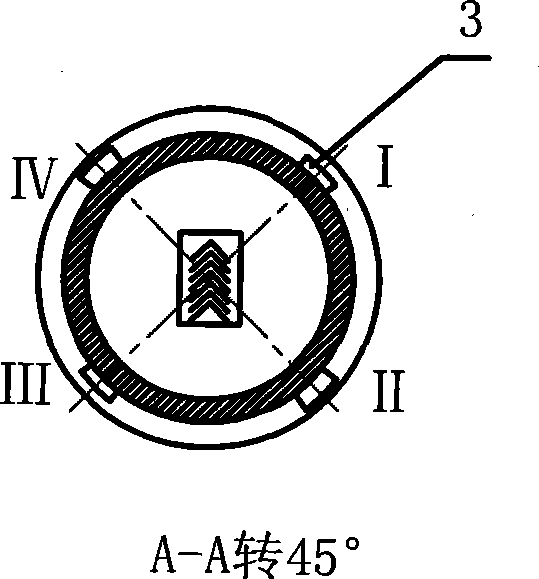

[0026] The plug-in wheel load force sensor, the circular cylinder is provided with a deformation control area 1, a sensitive area 2 and an isolation area 4. The sensitive area is attached with a strain gauge 6, and the cylinder is equipped with a compensation plate 5, outside the sensor The end is connected with a shielded cable 8, and the outer wall of the cylinder is provided with four circumferentially evenly distributed and radially symmetrical ribs 3, the height of the two ribs in the radial direction of I-III is lower than that of the two ribs in the radial direction of II-IV height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com