Novel bearing removal method

A bearing disassembly device and bearing technology, applied in the fields of connection, disassembly or clamping, and fastening, to achieve the effects of improving operating efficiency, reducing preparation requirements, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

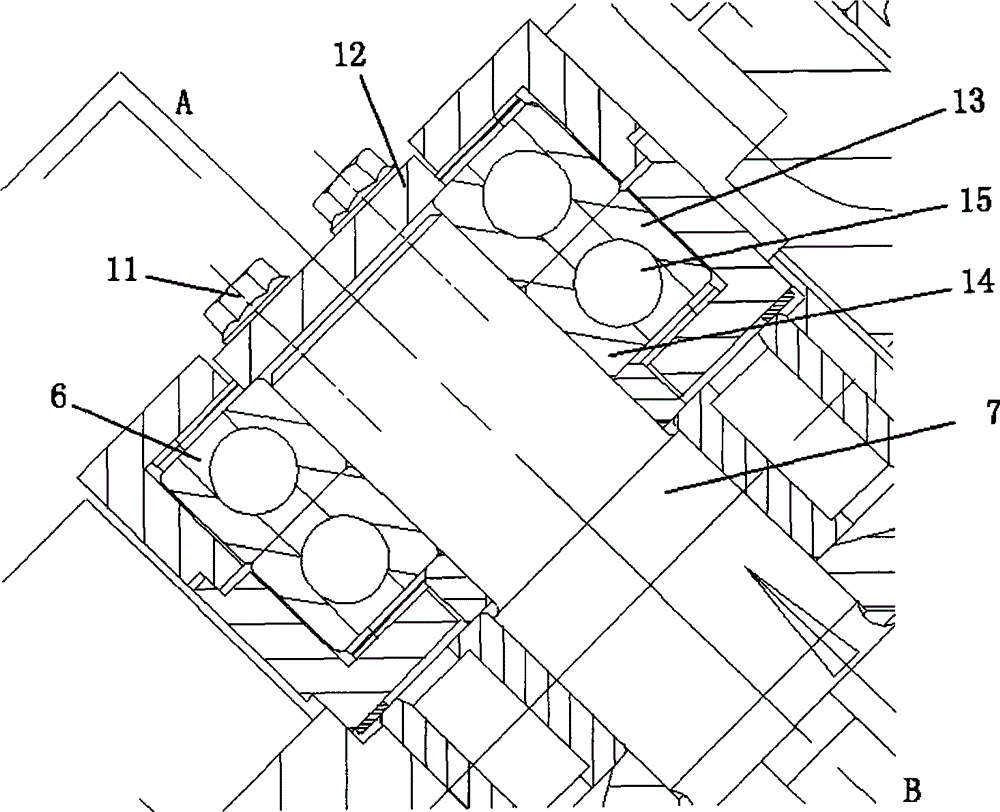

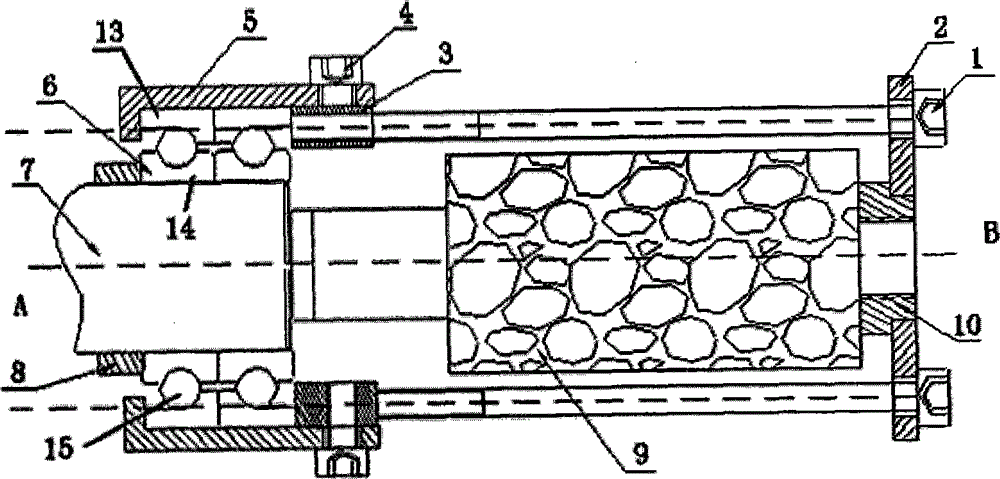

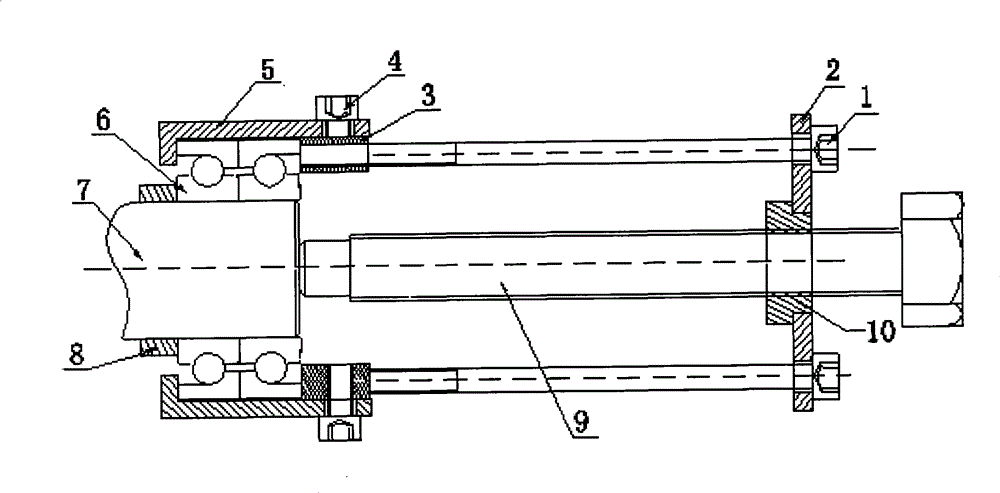

[0048] Embodiment 1: New bearing removal device (when using a jack):

[0049] The novel (multifunctional) bearing removal device of the present invention comprises: 1—M12*160 inner hexagonal bolt; 2—top plate; 3—drawing claw fixing ring; 4—M12*25 inner hexagonal bolt; 5—arc-shaped pulling claw; 10 -Nut ring.

[0050] Three hexagon socket bolts 1 pass through the top plate 2 and arrange three through holes at 120°. The threads of the head of the hexagon socket bolt 1 are screwed into the claw fixing ring 3 and three M12 threaded through holes are arranged at 120° in the axial direction. In this way, the most stable and reliable mechanical mechanism is formed structurally.

[0051] step 1:

[0052] Disassemble the shaft end pressure plate bolt 11 and the shaft end pressure plate 12, pull out the upper bearing seat and the lower bearing seat, and now only a pair of bearings are left at the shaft end, and then the bearing can be disassembled with the bearing dismounting device ...

Embodiment 2

[0063] Embodiment 2: Work when using bolts instead of hydraulic jacks:

[0064] Like embodiment 1, the difference is that the bolt 9' of M24 is used instead of the hydraulic jack to work, and its working principle is the same as above, wherein the nut ring 10 and the bolt 9' of M24 use the torque generated when the thread works to complete the disassembly work. This allows operation without hydraulic jacks, increasing its flexibility and practicality.

[0065] The structure that the nut ring 10 and the top plate 1 are designed into two bodies is to reduce the weight of the whole top plate while ensuring the bearing capacity of the thread. After many times of use, if the thread is damaged, you only need to replace the thread and ring instead of the entire top plate, which can reduce the consumption of metal raw materials and reflect the idea of energy saving.

[0066] In the above embodiment, when the bearing is disassembled by the new type bearing dismounting device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com