Shuttle driving device of sewing machine

A driving device and sewing machine technology, applied in the direction of sewing machine components, sewing machine ring mechanism, sewing equipment, etc., can solve problems such as difficult adjustment operations, and achieve the effect of suppressing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

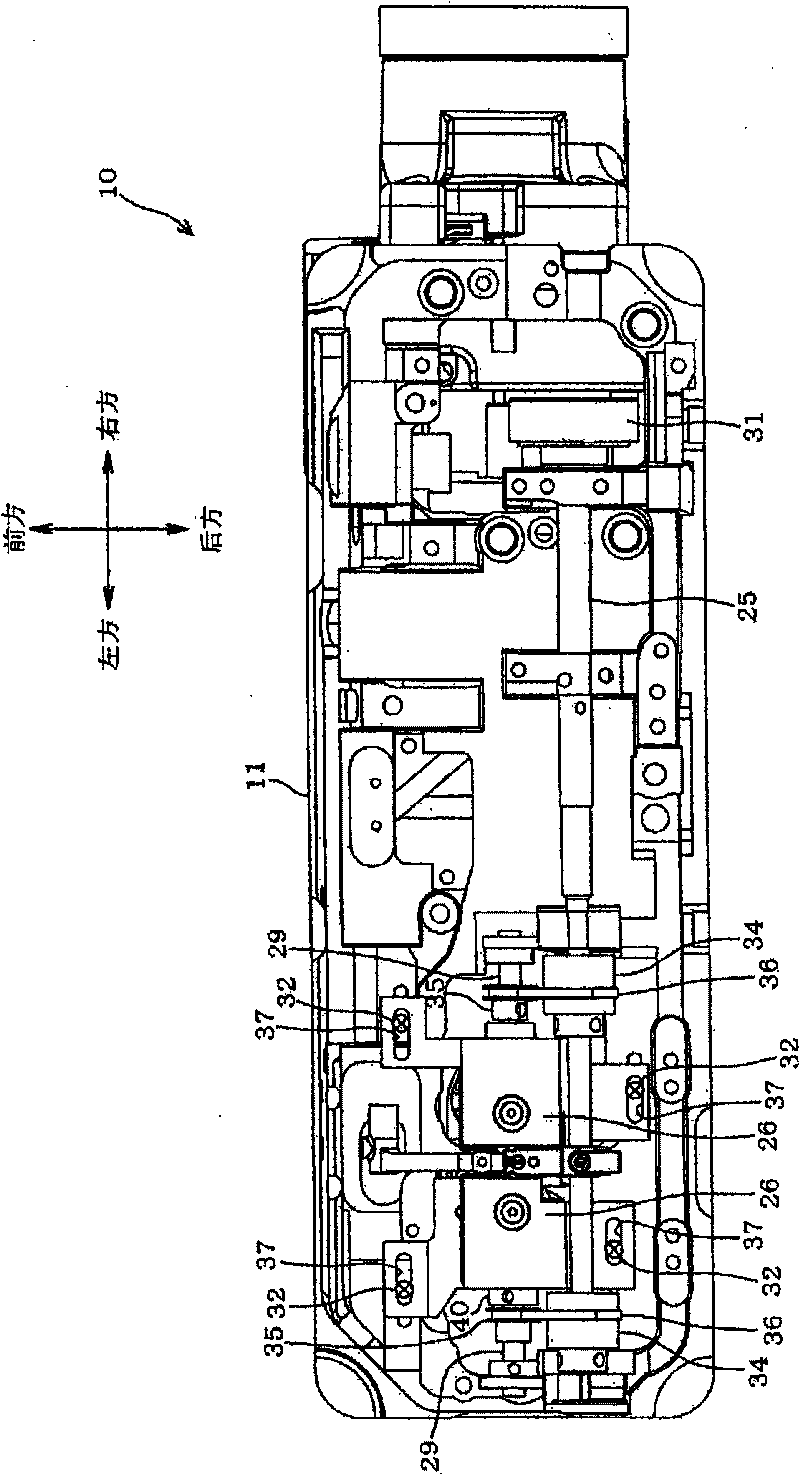

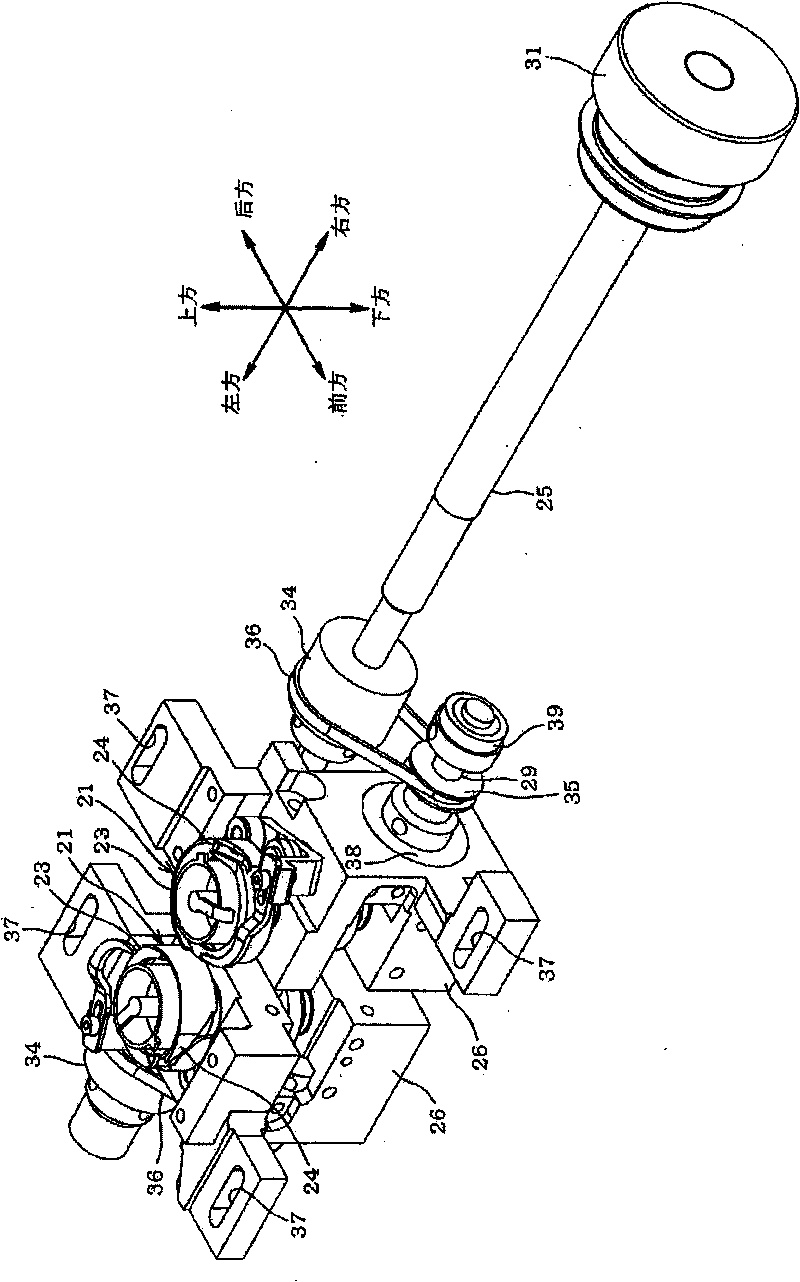

[0031] The present invention will be described in detail below with reference to the drawings showing preferred embodiments. The directions of up and down, front and back, and left and right used in the following descriptions are in Figure 1 to Figure 7 Indicated by arrows.

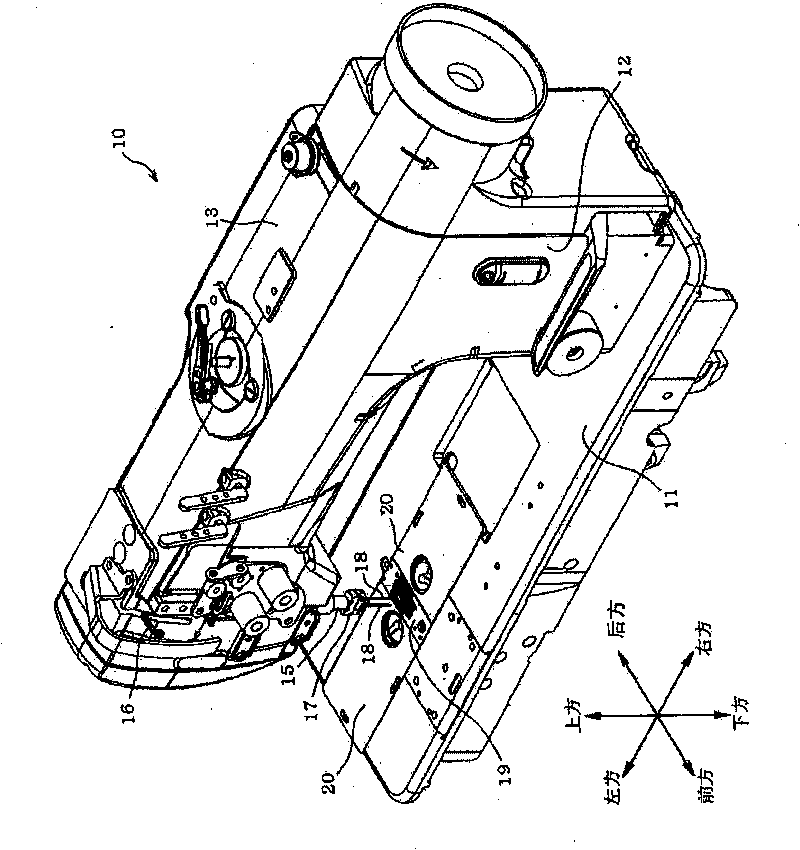

[0032] Such as figure 1 As shown, a double needle sewing machine 10 includes a base 11 , a support 12 and an arm 13 . The base 11 has a flat upper surface extending in the horizontal direction. The pillar 12 is provided at the right end portion of the base 11 to stand upward. The upper part of the strut 12 supports the base end part of the arm 13 . The arm 13 extends leftward parallel to the base 11 . The arm 13 supports a main shaft (not shown) therein. The main axis extends in the left-right direction. The main shaft is driven to rotate by a sewing machine motor (not shown).

[0033] The double-needle sewing machine 10 has a needle bar 15 and a thread take-up lever 16 at the front end of an arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com