Pressure resistance and pull-out resistance grouted gravel pile

A kind of gravel pile and grouting technology, applied in sheet pile wall, soil protection, construction and other directions, can solve the problem of inability to meet the anti-floating problem, improve the compressive and pull-resistant performance, the construction process is simple, and the economic benefits are good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

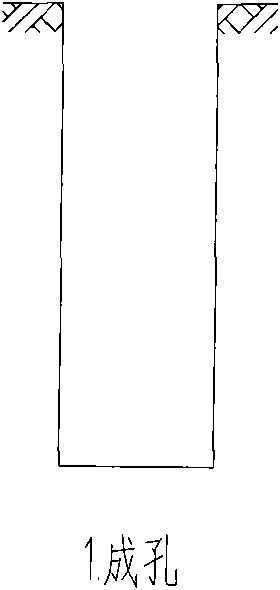

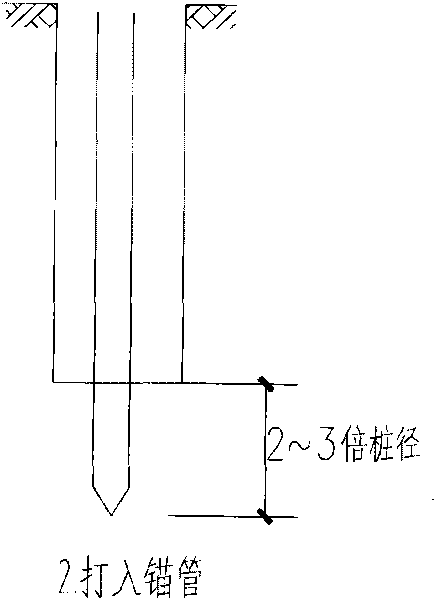

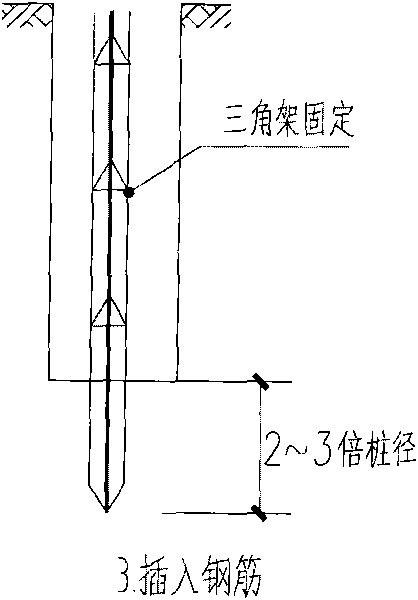

Embodiment 1

[0020] A grouted gravel pile with a pile length of 15m and a pile diameter of 0.8m is constructed on the clay foundation. Vibro punching is used to make holes at good hole positions. When making holes, the self-weight of the vibrator is used to slowly drop, and the hole making can be stopped when the designed hole depth is reached. After the hole is made and cleared, the anchor pipe (welded anchor pipe) with a length of 17m and a diameter of 89mm is hoisted into the hole and statically pressed until it is tangent to the ground, so that the anchor pipe penetrates 2m into the soil layer at the bottom of the pile. Fine-tune the position of the anchor tube so that it is vertically located in the center of the pile. Insert a grade III steel bar with a length of 17m and a diameter of 25mm into the anchor pipe, and fix it centered by welding a tripod on the steel bar. After the construction of the anchor pipe is completed, fill the hole from around the opening of the gravel pile, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com