Water chilling unit with self freeze-proofing function

A chiller and functional technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of unusable circulating pump, high system operating cost, high circulating pump power, etc., to prevent freezing danger and reduce antifreeze energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

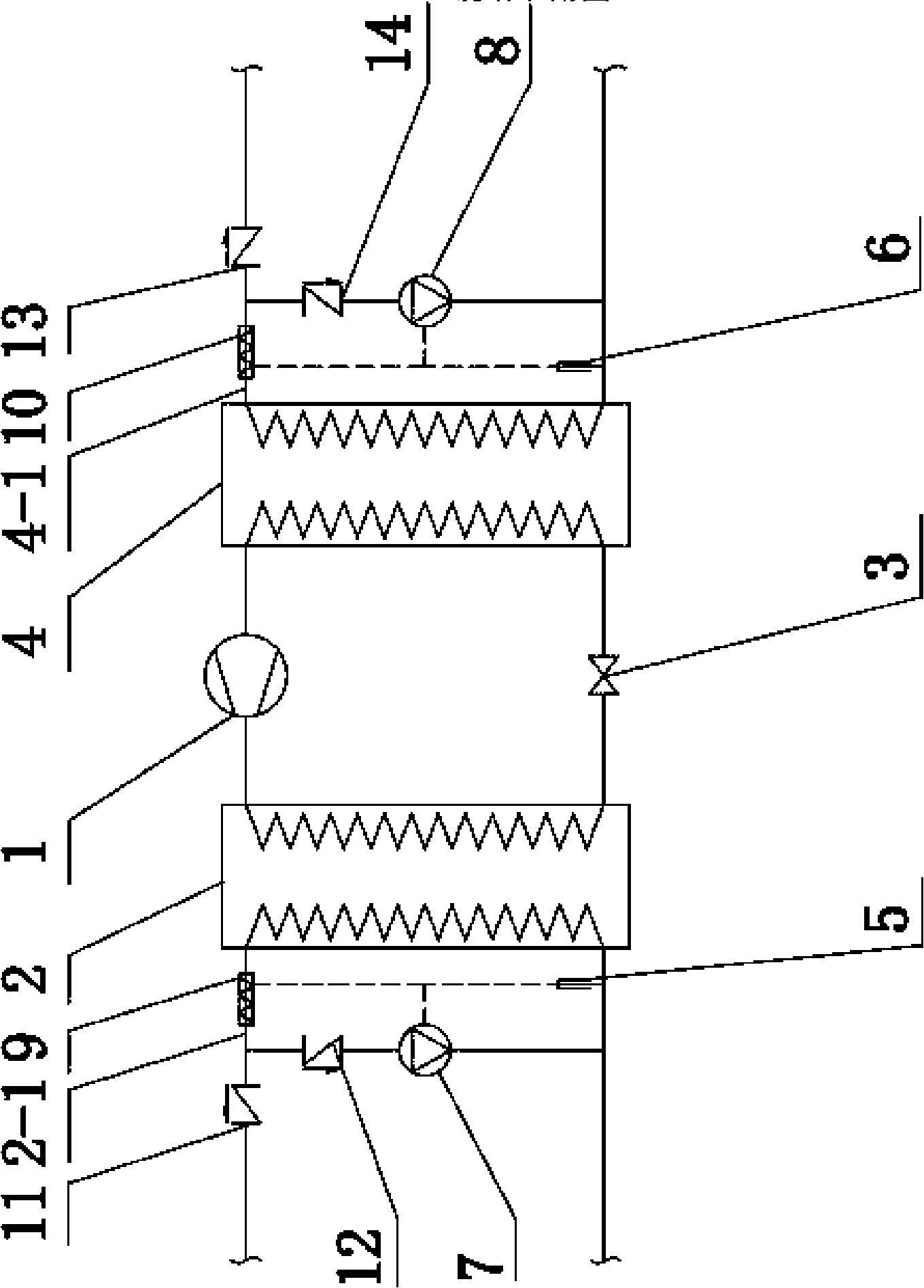

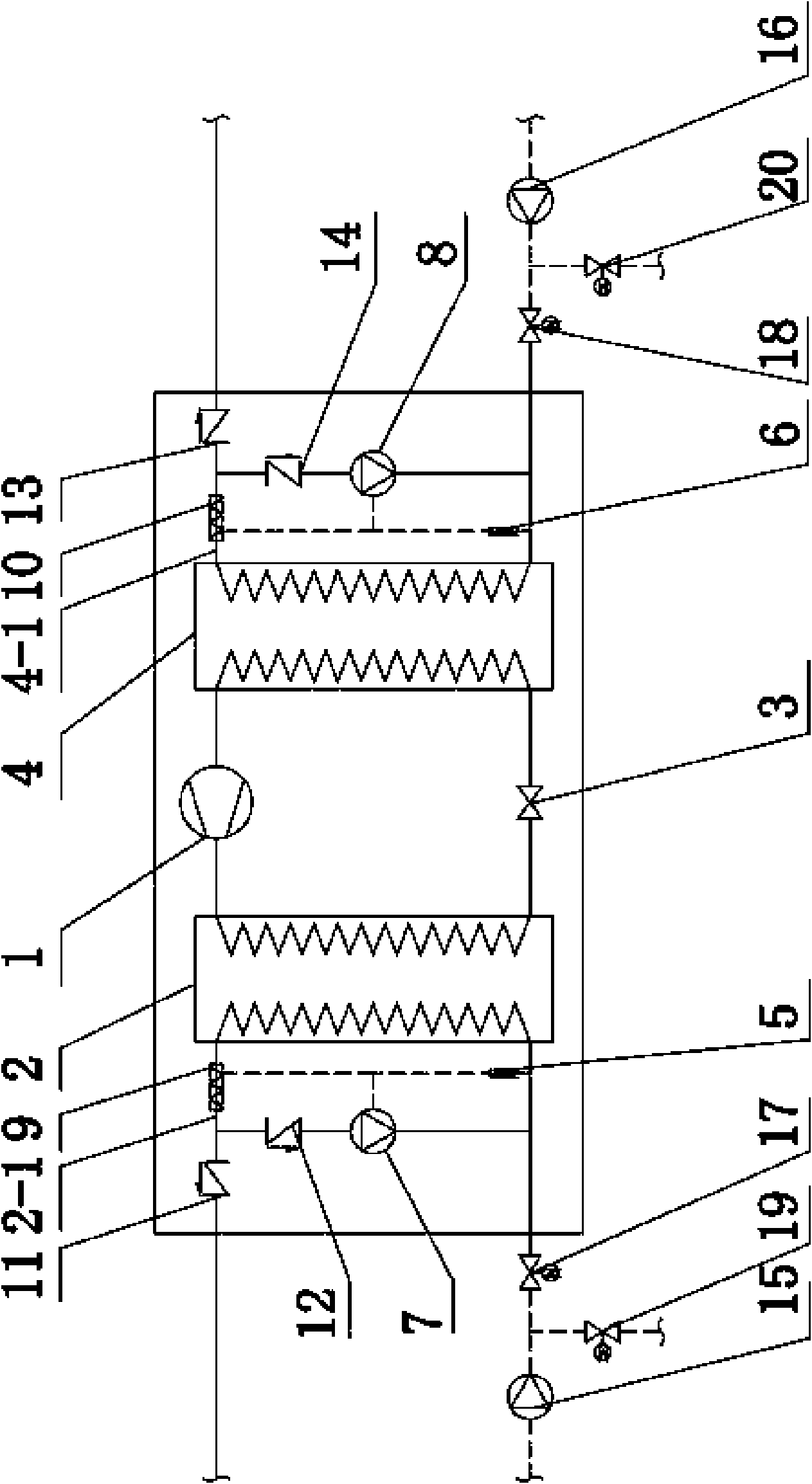

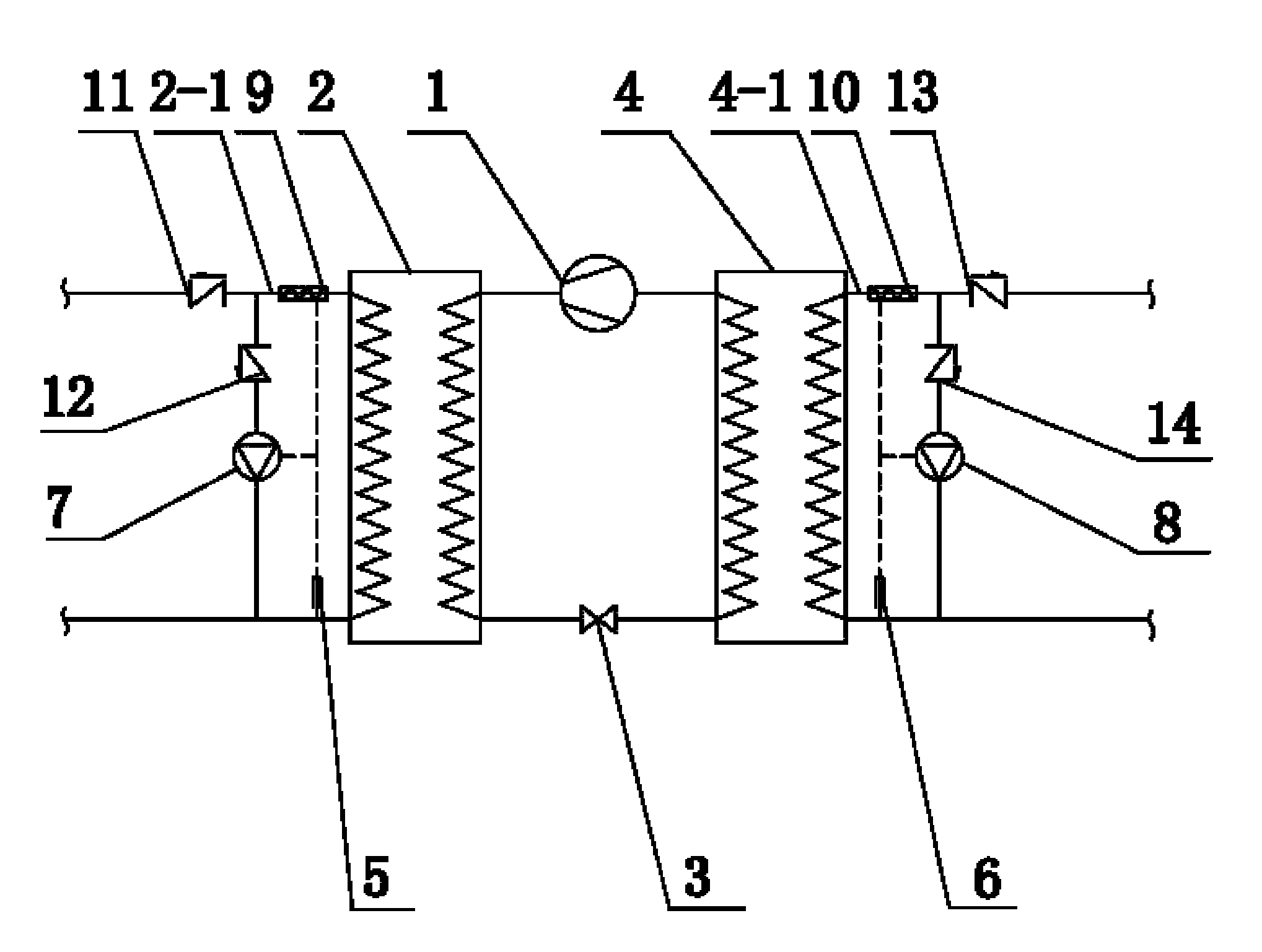

[0008] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the water chiller of this embodiment includes a compressor 1, a condenser 2, a first outlet pipeline 2-1, a throttle valve 3, an evaporator 4, a second outlet pipeline 4-1, a first water pipe Road temperature sensor 5 and the second water pipeline temperature sensor 6, the refrigerant outlet of the evaporator 4 communicates with the inlet of the compressor 1, the outlet of the compressor 1 communicates with the refrigerant inlet of the condenser 2, and the condensing The refrigerant outlet of the device 2 communicates with the refrigerant inlet of the evaporator 4 through the throttle valve 3, and the chiller also includes a first antifreeze circulating water pump 7, a second antifreeze circulating water pump 8, a first heating cable 9, a second heating cable Heat belt 10, first check valve 11, second check valve 12, third check valve 13 and fourth check valve 14, the cooling water outlet ...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 This embodiment will be described. The first water pipeline temperature sensor 5 of this embodiment is a thermocouple or a thermistor sensor.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 Describe this embodiment, the second water pipeline temperature sensor 6 of this embodiment is a thermocouple or a thermistor sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com