Swivel clamp for overhead transmission line spacer

A technology of overhead transmission lines and swivel lines, applied in the direction of the device for maintaining the distance between parallel conductors, etc., can solve the problems of discontinuous and unsmooth rotation, and achieve the effect of flexible and reliable rotation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

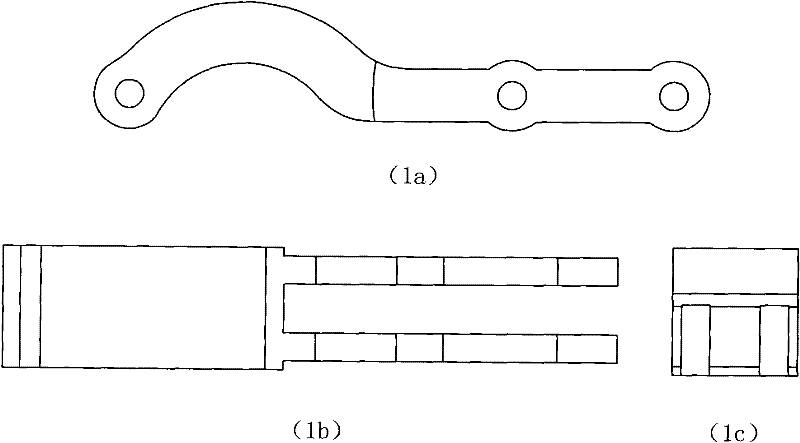

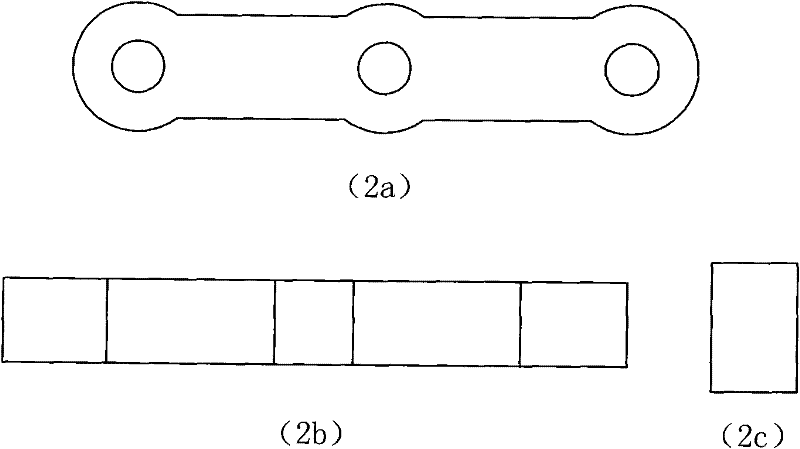

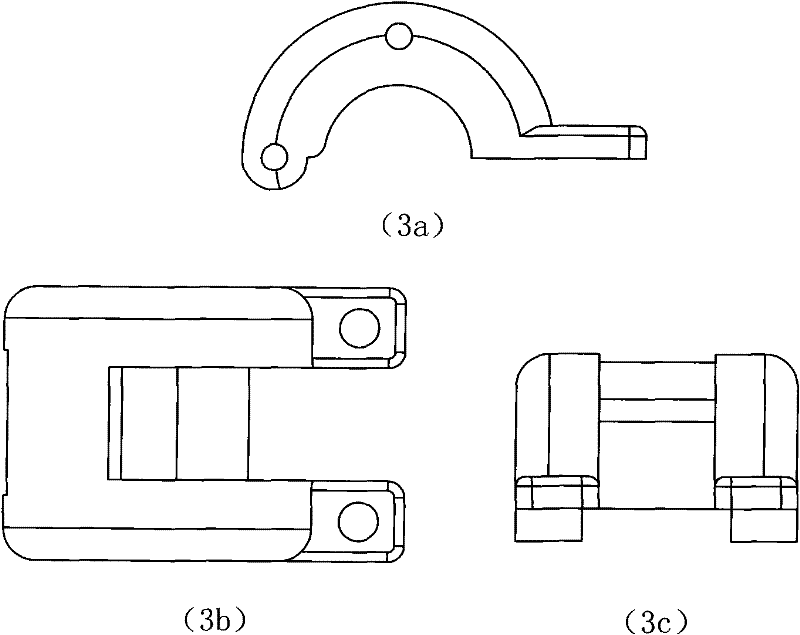

[0032] like figure 1 Shown is a three-dimensional schematic view of the rotary clamp used for overhead transmission line spacers according to the present invention. The rotary clamp body includes a semicircular arc-shaped first line clamp chuck 4 and a semicircular arc-shaped second wire clamp chuck 5 , two arc-shaped first rotary rods 6 and two linear second rotary rods 7, the first wire clamp chuck 4 is hinged with the two first rotary rods 6, and the second wire clamp chuck 5 is hinged with two second rotary rods 7, the two first rotary rods 6 are hinged with two second rotary rods 7, and the two second rotary rods 7 are hinged with the clamp support body 3; the first The two rotary rods 7 rotate in a circle with their own symmetrical center as the axis. The two first rotary rods 6, the two second rotary rods 7, the first wire clamp chuck 4, and the second wire clamp chuck 5 form a fixed movement. The four-bar mechanism of the track, the first wire clamp chuck 4 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com