Hydraulic Drive Rotary Ratchet Stepping Linear Actuator

A linear drive, rotary ratchet technology, applied in the directions of engine components, valve details, valve operation/release devices, etc., can solve the problems of the complex structure of the control valve drive, the low control accuracy, and the inability to recycle and use, and achieve convenient underwater use. The effect of operation, small overall size, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

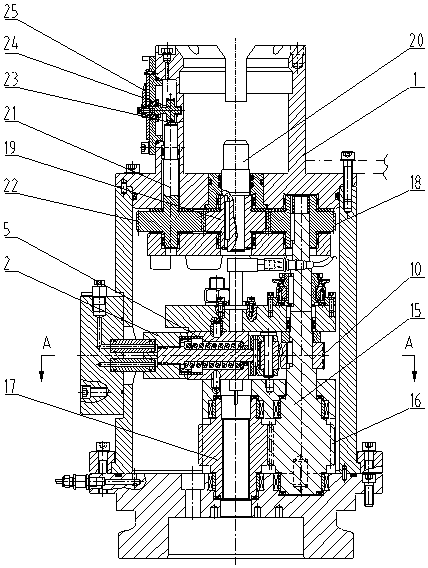

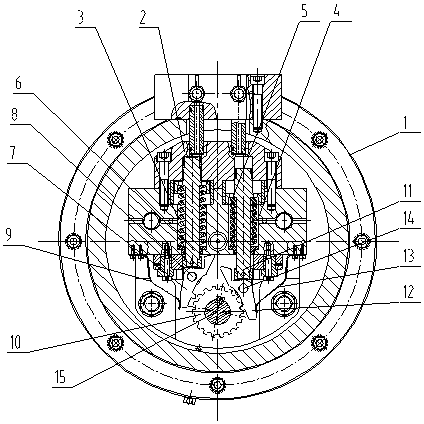

[0021] The hydraulically driven rotary ratchet stepping linear drive provided by this embodiment, such as figure 1 -As shown in -2, it includes a driver body 1, and a pressure cylinder assembly 2 is arranged on the driver body 1. The pressure cylinder assembly 2 in the driver of the present invention includes a first drive cylinder 3 and a second drive cylinder 4, and the first drive cylinder 3 and the second drive cylinder 4 can do two-way reciprocating movement, and are oil cylinders or air cylinders; the first drive cylinder 3 and the second drive cylinder 4 are respectively provided with return springs 5, and can return under the elastic force of the return spring 5 after moving; The first piston rod 6 of a driving cylinder 3 is arranged (or connected) in cooperation with the first pawl 7, the first pawl 7 rotates around the first rotating pin 8, and the first pawl 7 is provided with The first compression spring 9, the first compression spring 9 gives the spring action for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com