Steel rail quenching electric induction heating coil follow-up apparatus

A technology of induction heating coil and follower device, which is used in rails, heat treatment furnaces, rail maintenance, etc., can solve the problems of inability to guarantee the constant distance between the heating coil and the rail, increased friction, and inflexible lifting and lowering. Flexible and reliable lifting, reduce downtime, and reduce the effect of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

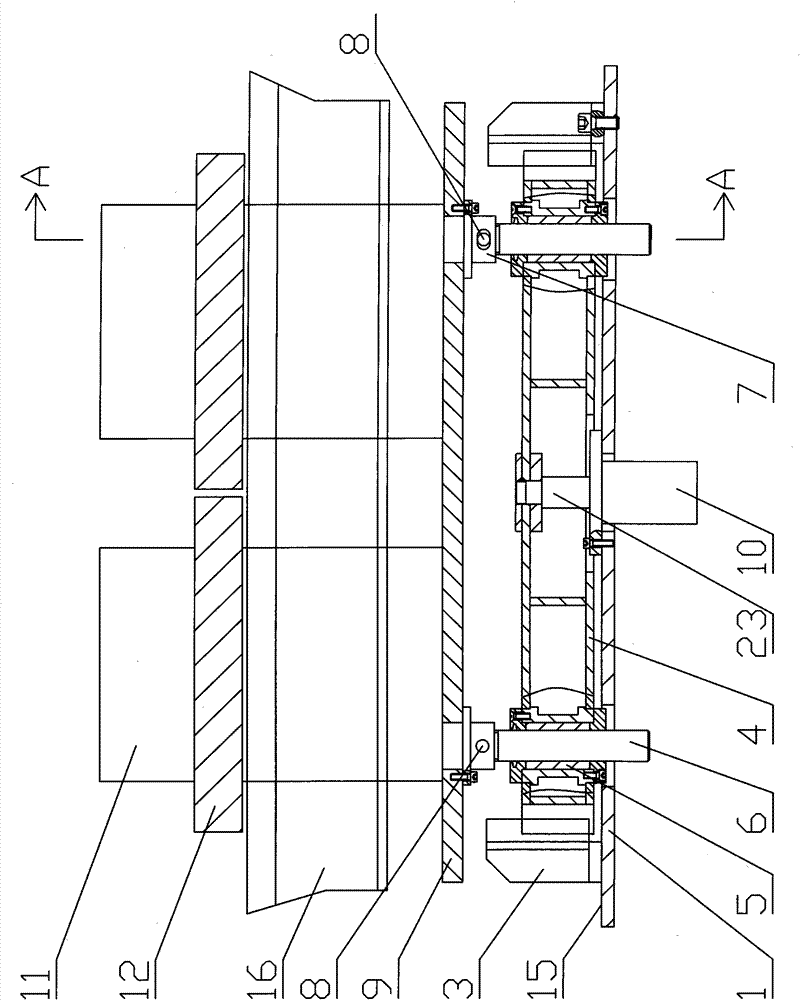

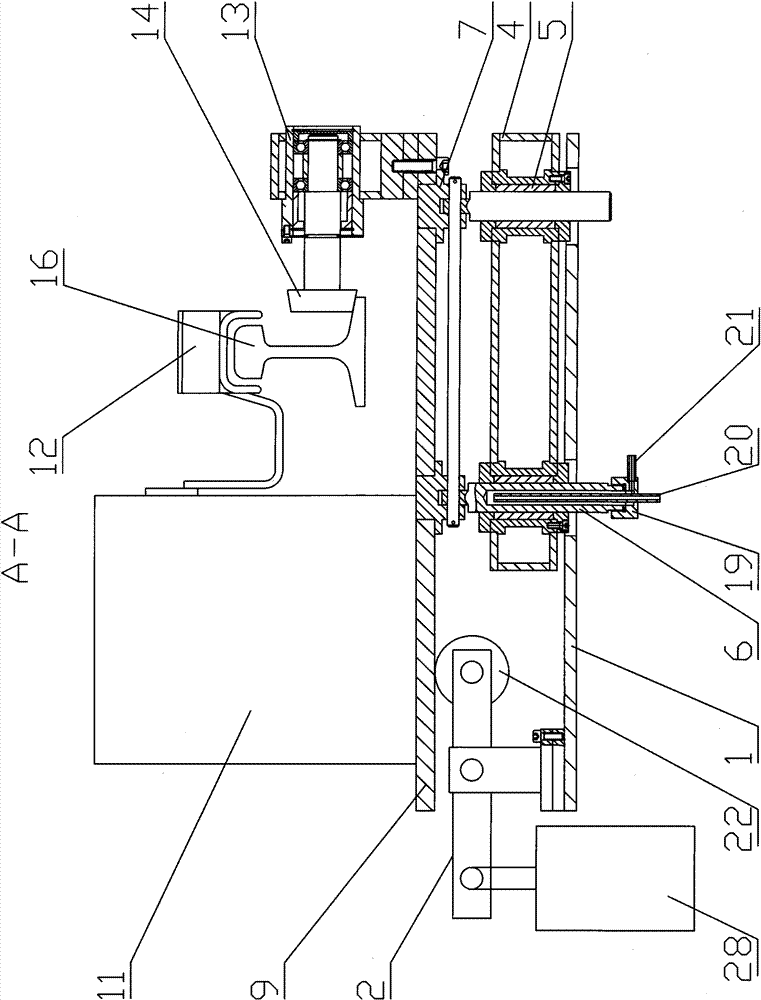

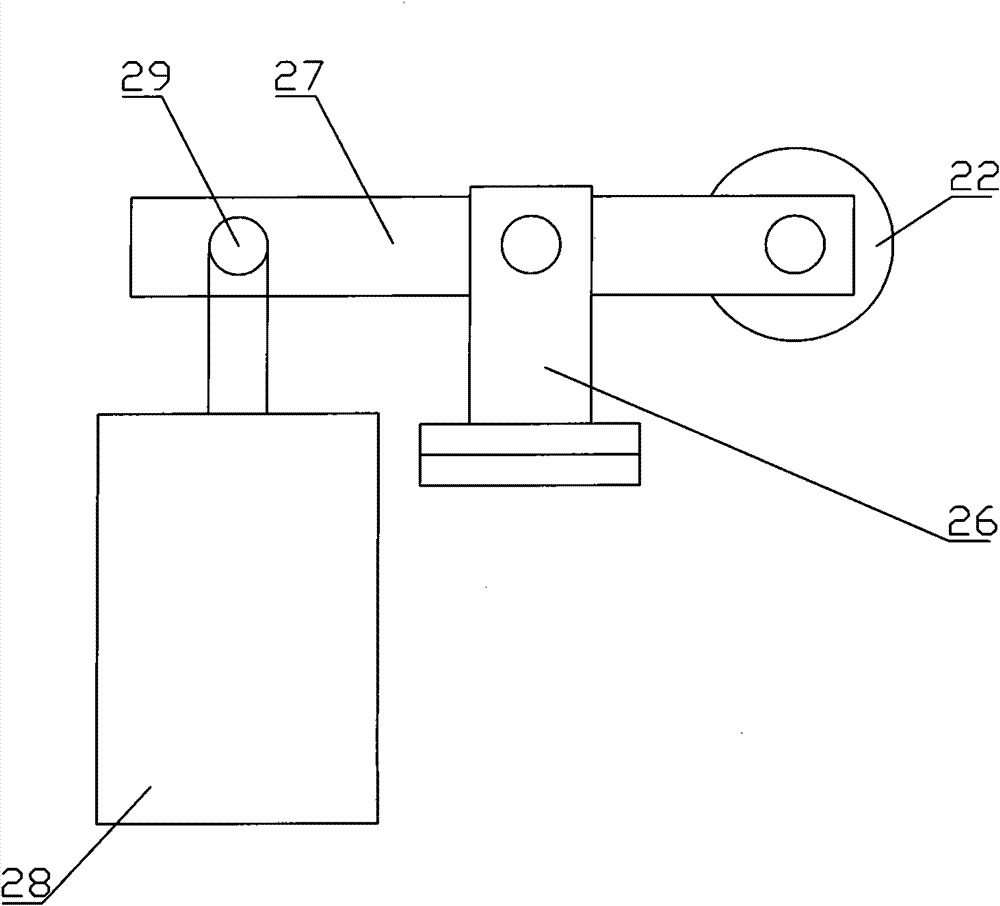

[0016] Specific implementation methods: such as figure 1 , figure 2 As shown, a rail quenching electric induction heating coil servo device includes a bed body 1, a counterweight support device 2, a guide rail 3, a linear bearing seat 4, a rolling linear bearing 5, a guide post 6, a rotating shaft seat 7, and a rotating shaft 8 , lifting connecting plate 9, oil cylinder 10, transformer 11, electric induction heating coil 12, tread wheel bearing seat 13 and tread wheel 14, wherein, the bed surface 15 side of bed body 1 is provided with counterweight supporting device 2, on the bed There are also at least four guide rails 3 on the surface 15, wherein at least two guide rails 3 are respectively placed on both sides of the symmetrical midline of the cross section of the heated steel rail 16, and the linear bearing housing 4 is placed on the four guide rails 3, and along the four guide rails 3 moves up and down, the linear bearing seat 4 is a hollow structure, such as Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com