Method for sinking bucket foundation with force bearing ring structure

A technology of cylindrical foundation and bearing ring, which can be used in basic structure engineering, construction, sheet pile wall, etc., can solve the problems of time-consuming cost and difficulty in sinking of cylindrical foundation, and achieve simple sinking process and automatic monitoring. The effect of operation, ensuring construction quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

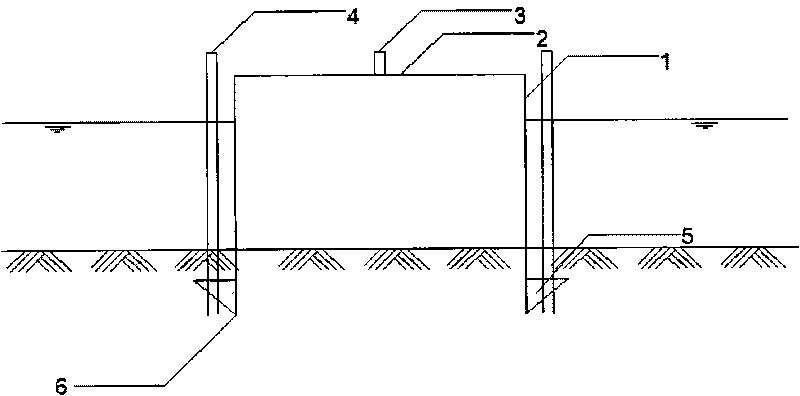

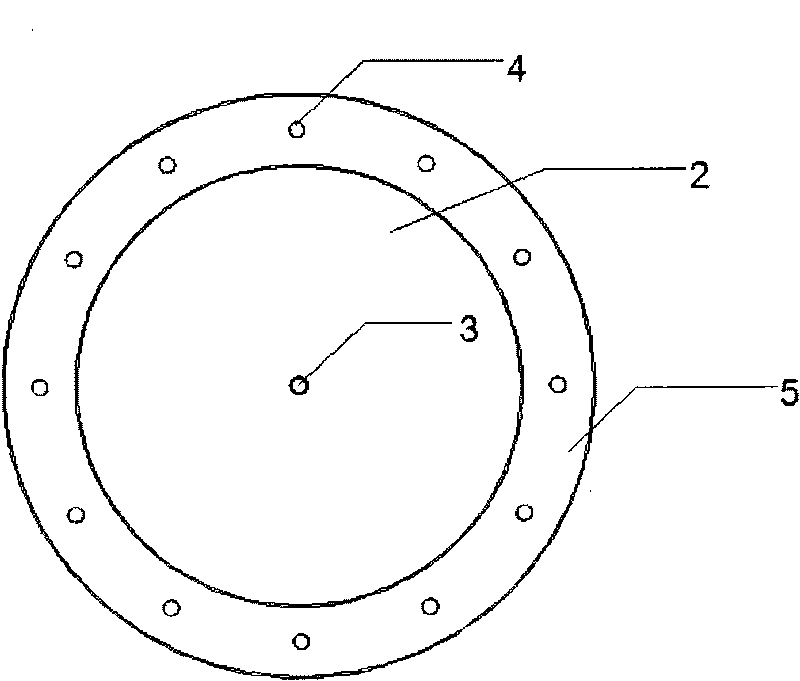

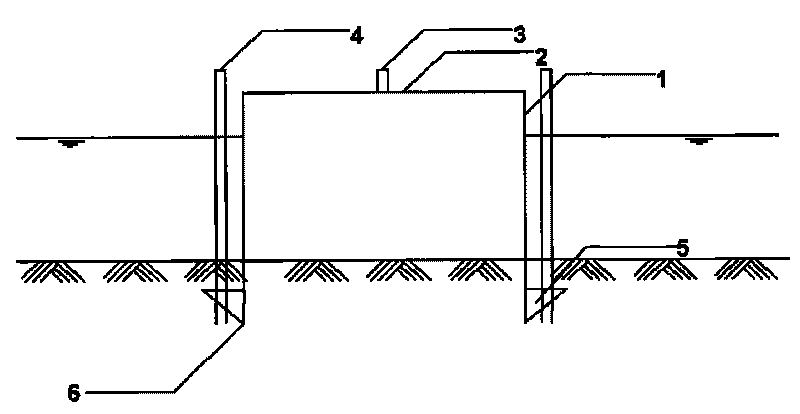

[0013] A sinking method for a cylindrical foundation with a load-bearing ring structure. The top of the cylindrical foundation 1 is provided with a sealed top cover 2, and the center of the sealed top cover 2 is provided with a reserved negative pressure hole 3 and is connected to a negative pressure system. A reserved gas injection pipe 4 is provided on the outside of the wall of the type foundation 1, and the outlet of the lower end of the reserved gas injection pipe 4 is located at the base layer 6 of the lower part of the bearing ring structure 5, and the upper end of the reserved gas injection pipe 4 is connected with the gas injection equipment on the water surface. The steps are as follows: 1) After the cylindrical foundation 1 sinks into place by its own weight, the reserved gas injection pipe 4 outside the wall of the cylindrical foundation 1 is activated, and the reserved gas injection pipe 4 is continuously provided to the foundation bottom layer 6 under the bearing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com