Homogenized silo circular arc net rack foundation structure

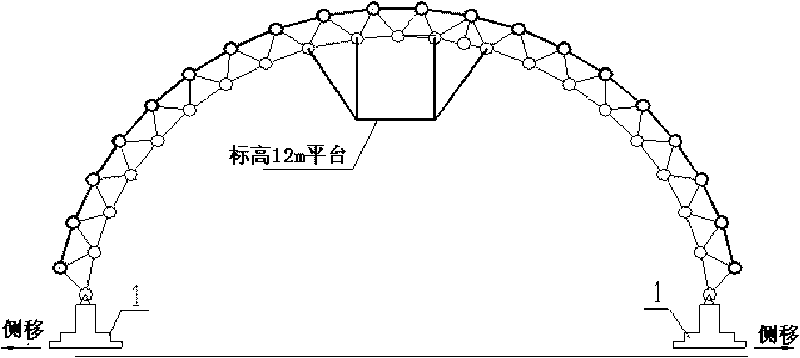

A basic structure and arc-shaped technology, which is applied in the field of the basic structure of the arc-shaped grid structure of the homogenization warehouse, can solve the problems of affecting normal production and poor safety, and achieve the effect of meeting the bearing capacity, improving safety, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

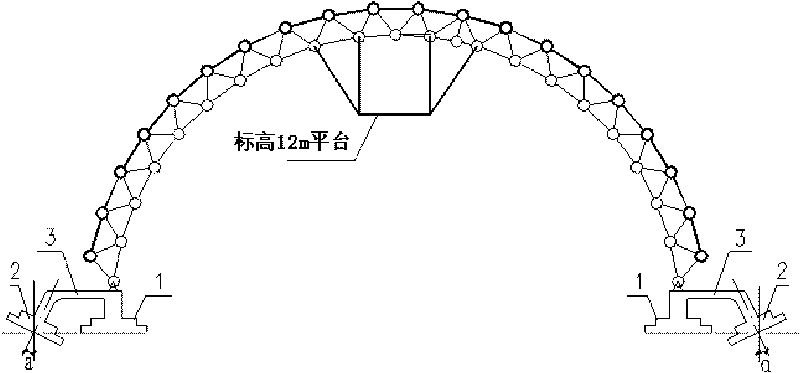

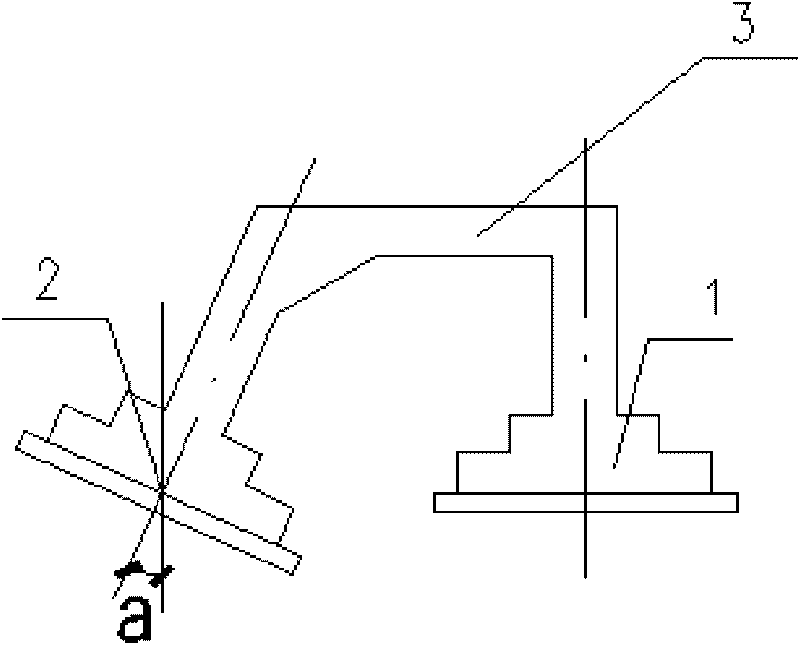

[0009] Embodiment of the present invention: make the foundation of the homogenization warehouse into an inner and outer double foundation, the inner foundation 1 and the outer foundation 2 are connected by the foundation beam 3, wherein the outer foundation 2 has an inclination angle α, and the value range of the inclination angle α is 15 °~60°. Here the inclination angle α is 25°. The horizontal force is transmitted through the foundation beam and the outer foundation, as attached image 3 Shown, resisting the horizontal force generated by the homogenized pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com