Method of determining graphic outer contour for optical proximity correction

A technology of optical proximity correction and outer contour, which is applied in photomechanical processing of originals, optics, and pattern surfaces for opto-mechanical processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The inventors of the present invention found that when performing optical proximity correction to determine the outline of the figure, there is redundancy in the test points used to determine the outline of the figure, such redundancy greatly increases the amount of calculation when performing optical proximity correction, and cannot adapt to Optical proximity correction for increasingly dense circuit layouts.

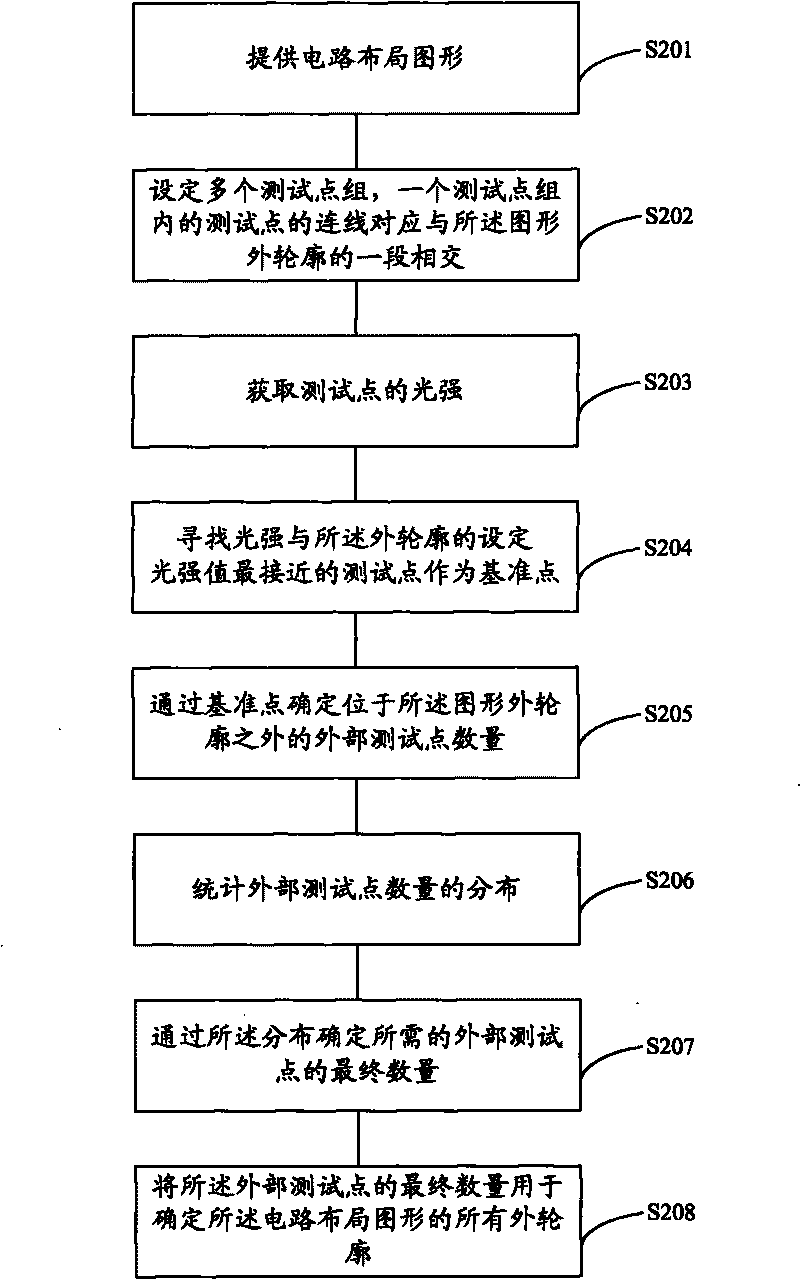

[0026] In order to reduce the redundancy of test points, according to an embodiment of the present invention, a method for determining the outer contour of a graph for optical proximity correction is provided, such as figure 2 shown, including steps:

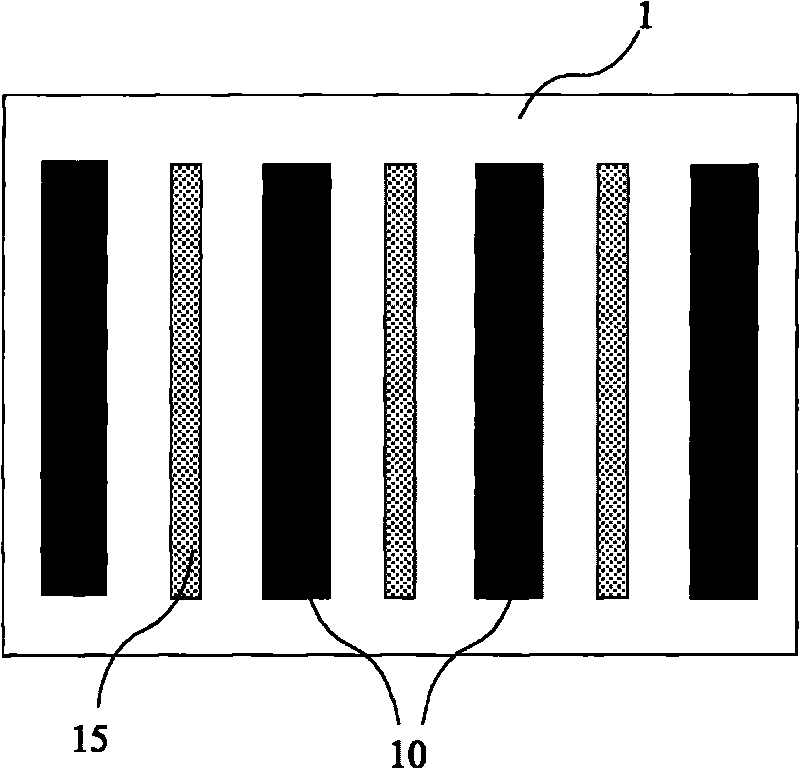

[0027] S201, providing circuit layout graphics;

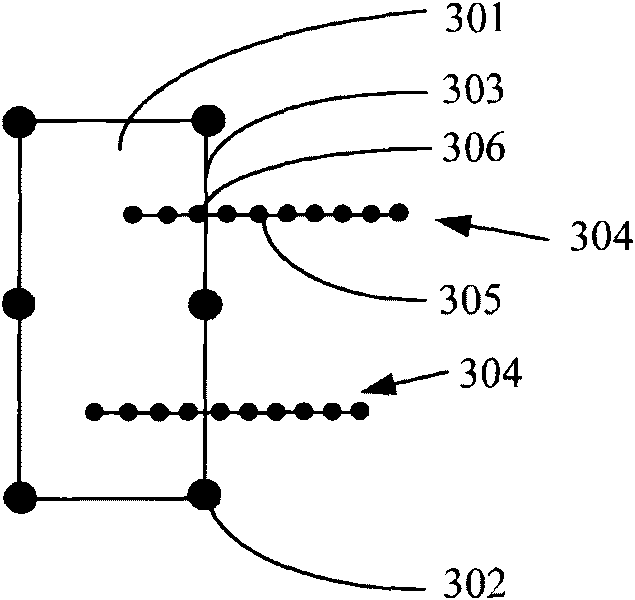

[0028] S202, setting a plurality of test point groups, the connection line of the test points in each test point group correspondingly intersects with a section of the outer contour of the graph;

[0029] S203, acquiring the light intensity of the test point;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap