Underground cable protective sleeve

A technology for protective sleeves and cables, which can be used in ground cable installation, cable installation in underground pipelines, cable installation, etc., and can solve problems such as labor-intensive, labor-intensive, and rough cutting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

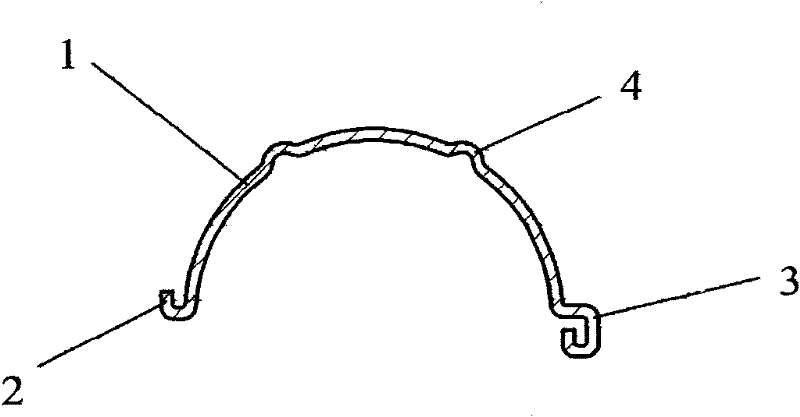

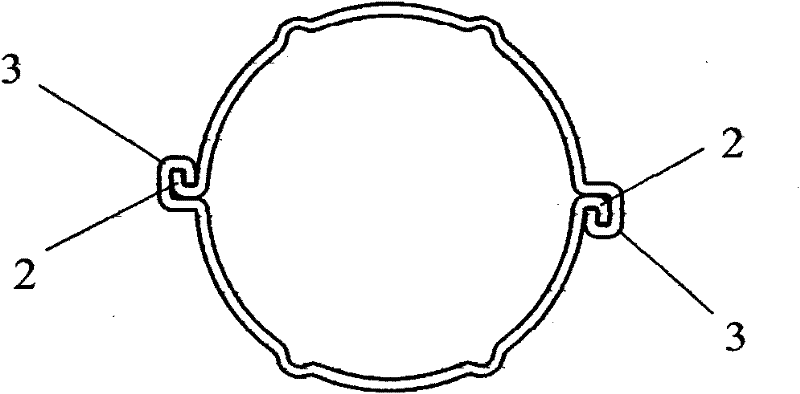

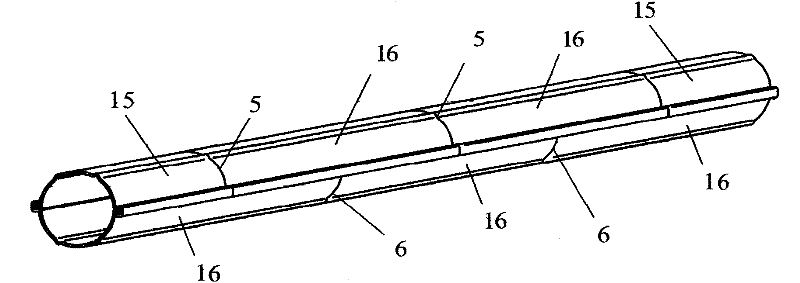

[0024] Such as image 3 As shown, the buried cable protective sleeve includes two sets of upper and lower semicircular tubes, and each set of semicircular tubes includes several sections of independent semicircular tubes. Such as figure 1 As shown, there is a flanging on both sides of each section of semicircular pipe 1, and these two flangings are respectively two types of flanging whose cross-sectional shape can be inserted into each other, wherein the cross-sectional shape of the first type of flanging 2 is outward Folded and then turned backwards, the cross-sectional shape of the second type of flanging 3 is to turn outwards, then forwards, then inwards and backwards. Such as figure 2 As shown, the upper group of semicircular tubes and the lower group of semicircular tubes are inserted together, the first type of flange 2 of the upper group of semicircular tubes is inserted into the second type of flange 3 of the lower group of semicircular tubes, and the first type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com