Automatic coating device for solar glass

A technology of solar glass and coating equipment, applied in the field of automatic solar glass coating equipment, can solve the problems of weakened anti-reflection effect, limited effect, easy entry of dust, etc., and achieve the effect of increased transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with specific embodiment, further set forth the present invention:

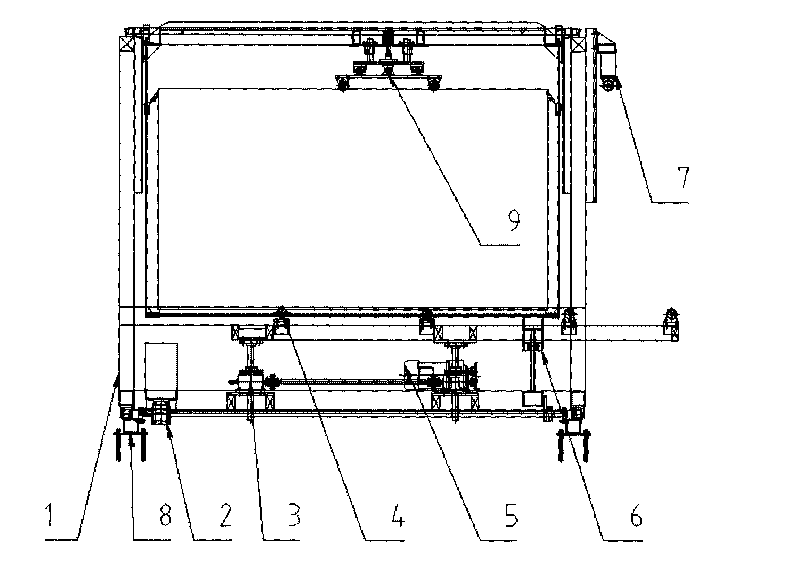

[0032] The automatic solar glass coating equipment of the present invention includes a glass feeding device running on a track, which can put solar glass into a glass hanger, and move the glass feeding device to an upper Material level: a manipulator transmission device, which can hang the glass hanger at the upper material level, and transport it to a coating tank for solar glass coating, and transport the coated solar glass to a drying device for drying ; A glass blanking device, through which the dried solar glass can be removed from the glass hanger, and the glass hanger that takes off the solar glass is moved to the glass feeding device by the moving device for solar glass Clamping.

[0033] Such as figure 1 As shown, it is a schematic structural diagram of the glass feeding and moving device in the present invention, which includes a mobile frame 1 that can run on a track 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com