Single wave beam guardrail plate and single wave beam steel guardrail

A technology for guardrails and guardrails, which is applied to bridges, bridge parts, bridge construction, etc., and can solve problems such as low protection level and large amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

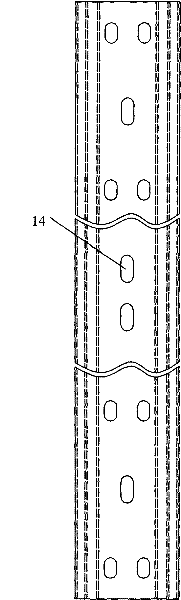

[0038] According to an embodiment of the present invention, a single-wave beam guardrail panel is provided. Such as figure 1 with figure 2 As shown, this embodiment includes a guardrail body 15 formed by integral rolling, and two energy gathering rings that are axially symmetrically distributed on the upper and lower edges of the guardrail body 15 and have the same structure. Among them, the cross section of the guardrail body 15 is arc-shaped; two energy gathering rings are spirally curled inward from the upper and lower edges of the guardrail body 15 toward the convex direction of the guardrail body 15 respectively.

[0039] Further, in the above two energy gathering rings, the cross section of each energy gathering ring is a pipe-in-pipe structure in which the first steel pipe 18 is sleeved on the inner wall of the second steel pipe 19, and the pipes of the first steel pipe 18 and the second steel pipe 19 The wall has a common section near the protrusion of the guardrail body...

Embodiment 2

[0047] The difference from the foregoing embodiment is that in this embodiment, in each tube-in-tube structure, the radius of the outer circle where the first steel tube is located is less than 55% of the radius of the outer circle where the second steel tube is located.

Embodiment 3

[0049] The difference from the foregoing embodiment is that in this embodiment, in each tube-in-tube structure, the outer radius of the first steel tube is less than 50% of the outer radius of the second steel tube.

[0050] Example of single wave beam steel guardrail

[0051] Example one

[0052] According to the embodiment of the present invention, a single-wave beam steel guardrail is provided based on the single-wave beam guardrail panel described above. Such as image 3 As shown, this embodiment includes multiple guardrail units arranged in a horizontal sequence, and the multiple guardrail units are assembled and connected; among the multiple guardrail units, the single-layer guardrail board subunit in each guardrail unit is connected to the adjacent guardrail unit The assembly connection between the corresponding guardrail board sub-units. Here, the number of guardrail units can be set according to the actual length of the road or bridge; in addition, the structure of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com