Rotary guiding composite material bumper

A composite material, rotation-oriented technology, used in shipping equipment, climate change adaptation, etc., can solve the problems of insufficient strength, anti-corrosion, and unreachable bumpers, and achieve good impact resistance and good corrosion resistance. , the effect of reducing the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

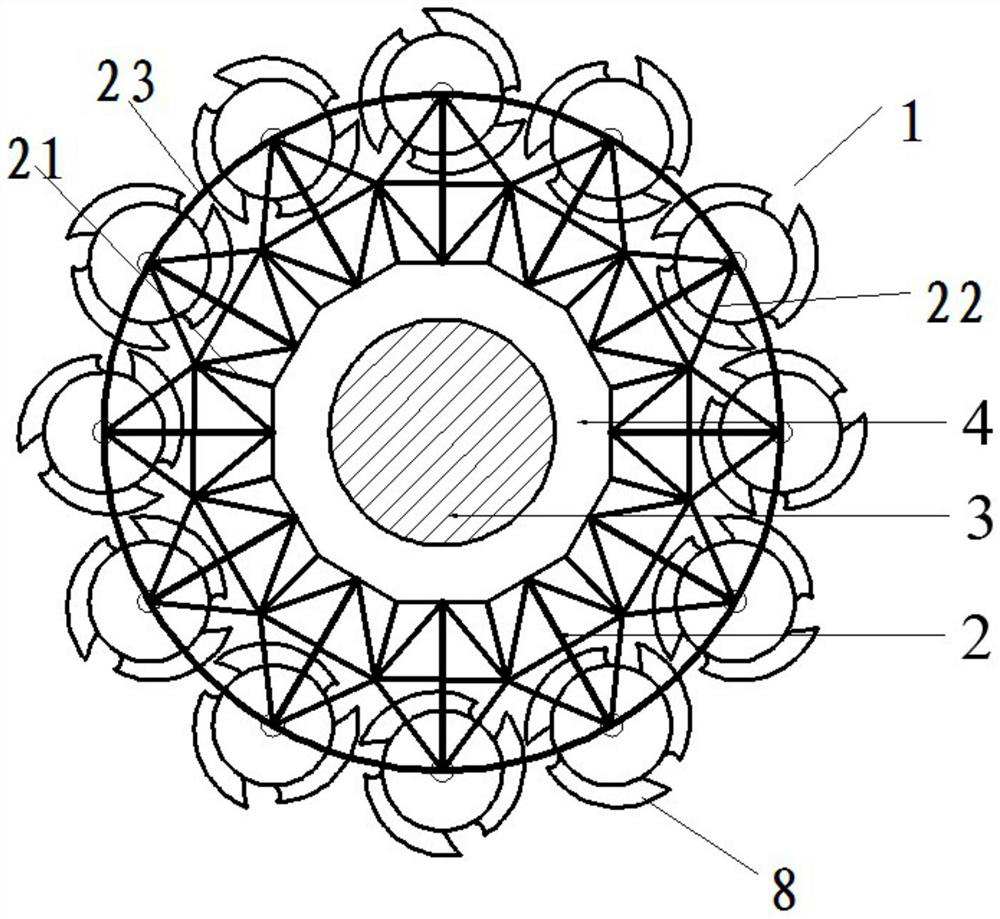

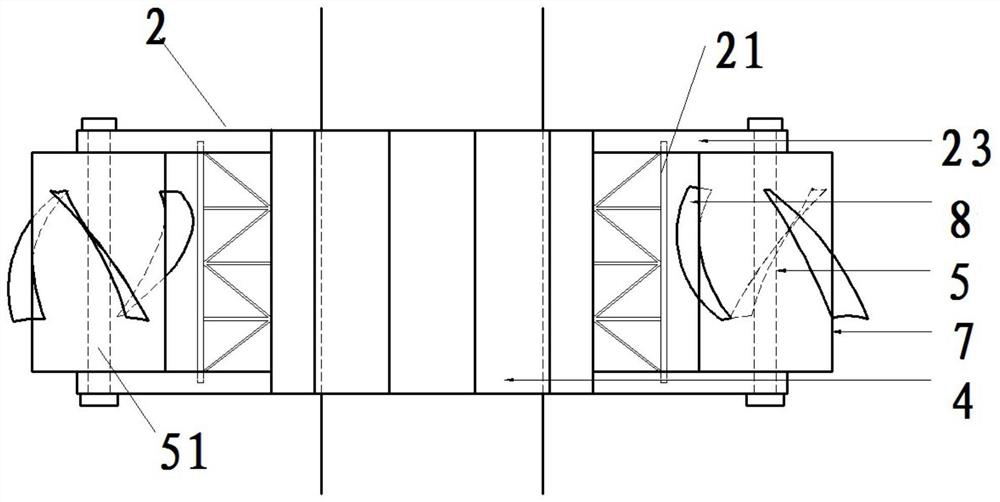

[0026] Lower binding Figure 1-5 The specific embodiments of the present invention will be described in detail.

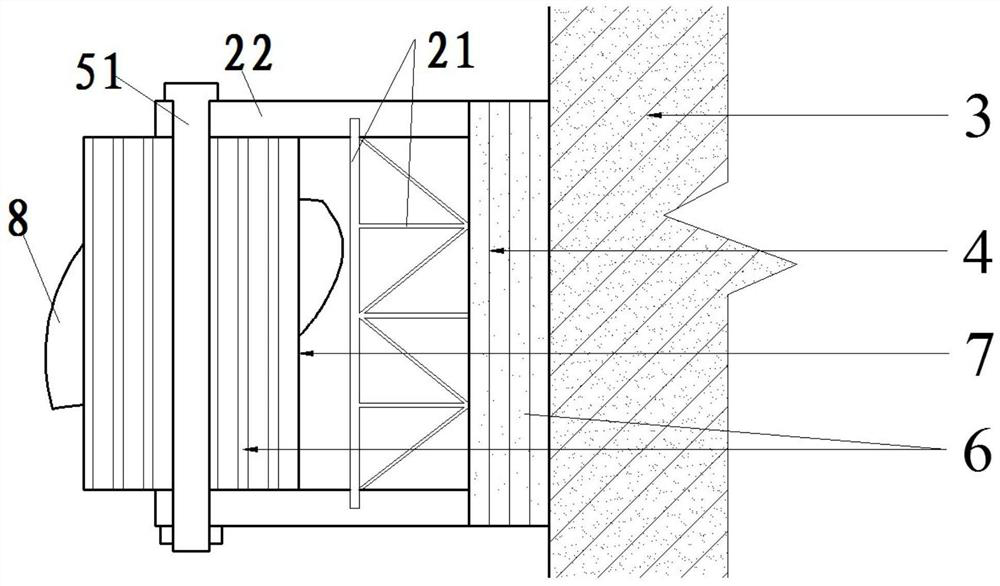

[0027] like figure 1 , shown in 5, a kind of rotation guide composite material bumper of the present invention, comprises bumper single structure 1, bracket 2 and platform 4, and circular platform 4 surrounds and connects pile body 3 periphery, and platform 4 periphery connects A bracket 2 is provided, and several single structures 1 of the bumper are connected through the bracket 2 and arranged on the outer periphery of the bracket 2 . The bracket 2 is assembled with nylon rods, and the nylon rods are connected together by pins.

[0028] like figure 2 As shown, the single structure 1 of the bumper is a winged bucket structure connected to the platform 4 through the bracket 2, which is composed of the inner shell 5, the outer shell 7, the extended wings 8 and the foam energy-absorbing filler 6. like image 3 As shown, the energy-absorbing filler 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com