Built-in anchor head embedded-type anchoring pile

An embedded and anchor head technology, applied in the field of foundation piles, can solve the problems of increasing the difficulty of drilling, limiting the number of anchor cables, increasing the total length of anchor cables, etc., to save concrete materials, control horizontal deformation, and reduce embedded depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

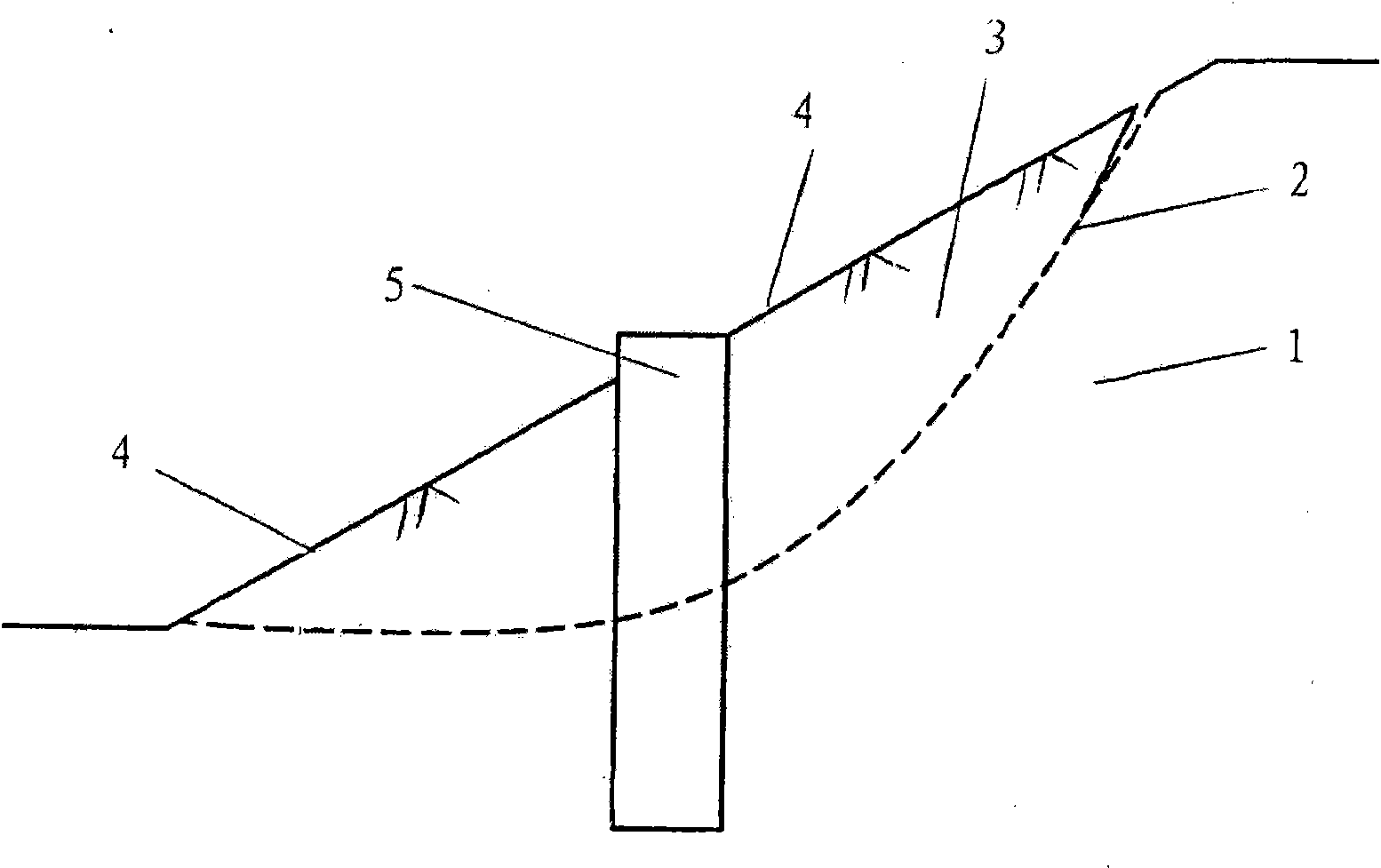

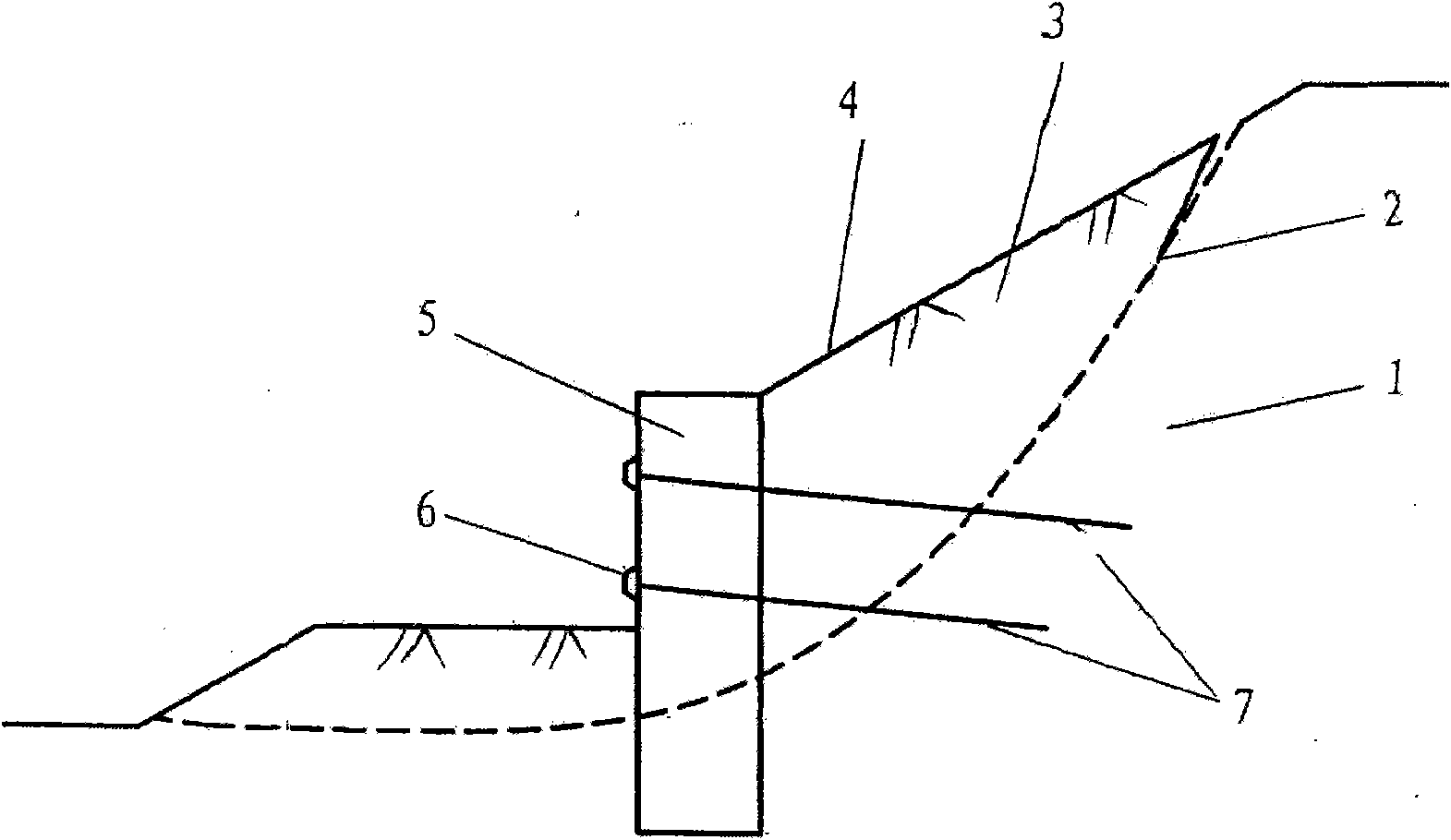

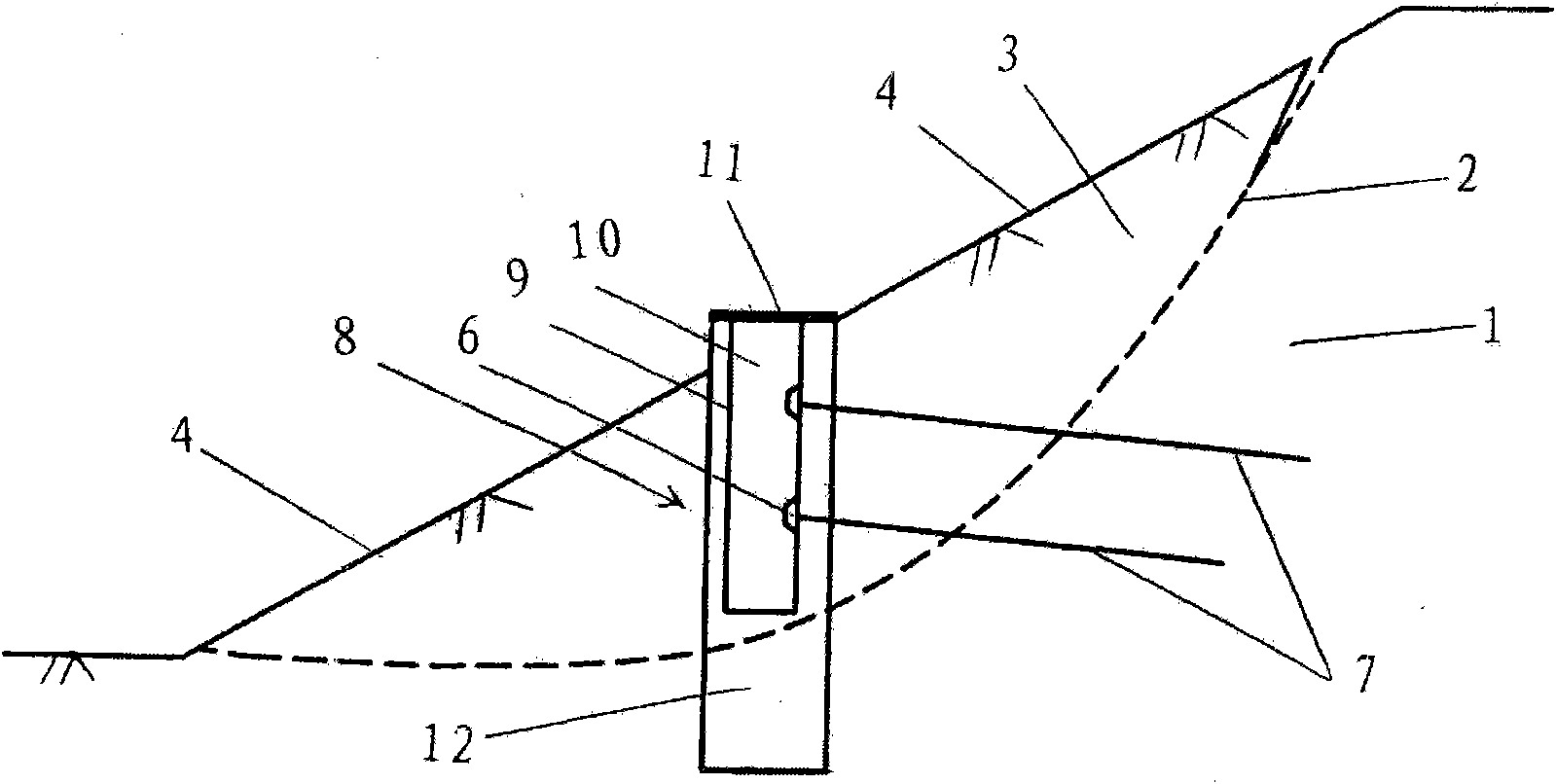

[0040] The specific structure and setting method of the embedded anchor pile with built-in anchor head involved in the present invention will be further described in conjunction with the accompanying drawings. image 3 Shows the state and basic structure of embedded anchor piles embedded in landslides with built-in anchor heads, Figure 4 Showing the cross-sectional structure of the hollow cavity of a buried anchor pile with a built-in anchor head.

[0041] As shown in the figure, the embedded anchor pile with built-in anchor head of the present invention includes a hollow anti-slide pile 8 , an anchor head 6 , an anchor cable 7 and a cover plate 11 . The hollow anti-slide pile 8 is a reinforced concrete pile with a rectangular pile section, and the two sides of the rectangular pile section are the pile section length L and the pile section width W respectively. The upper part of the hollow anti-slide pile 8 is a hollow body 9 forming a hollow cavity 10 inside, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com