Checking system for data communication of electromagnetic oven and application method thereof

A technology of data communication and induction cooker, which is applied in the field of data communication of induction cooker, can solve the problems of adopting software verification method, affecting real-time control, occupying microcontroller interruption and a lot of time, etc., and achieving the goal of increasing fault tolerance and improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

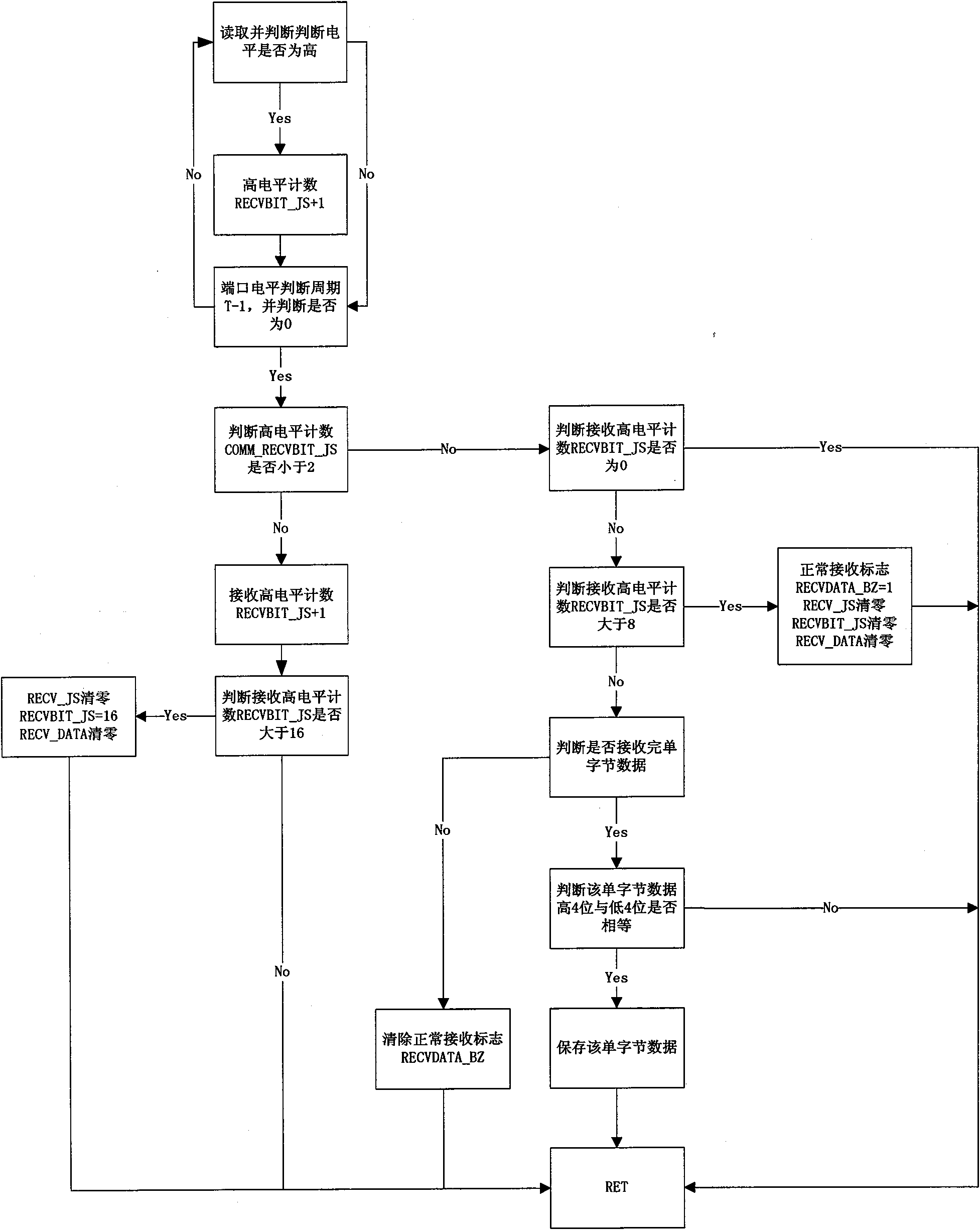

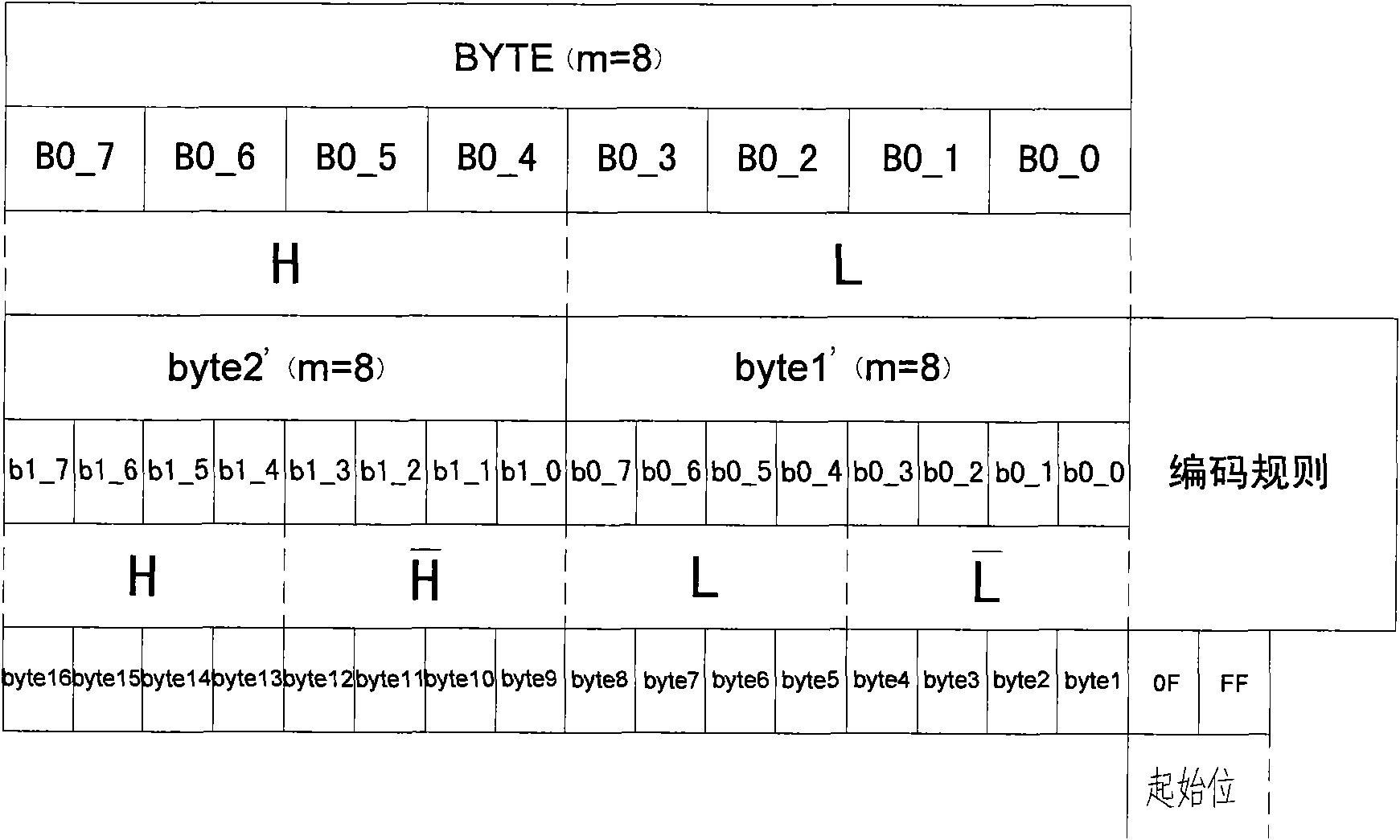

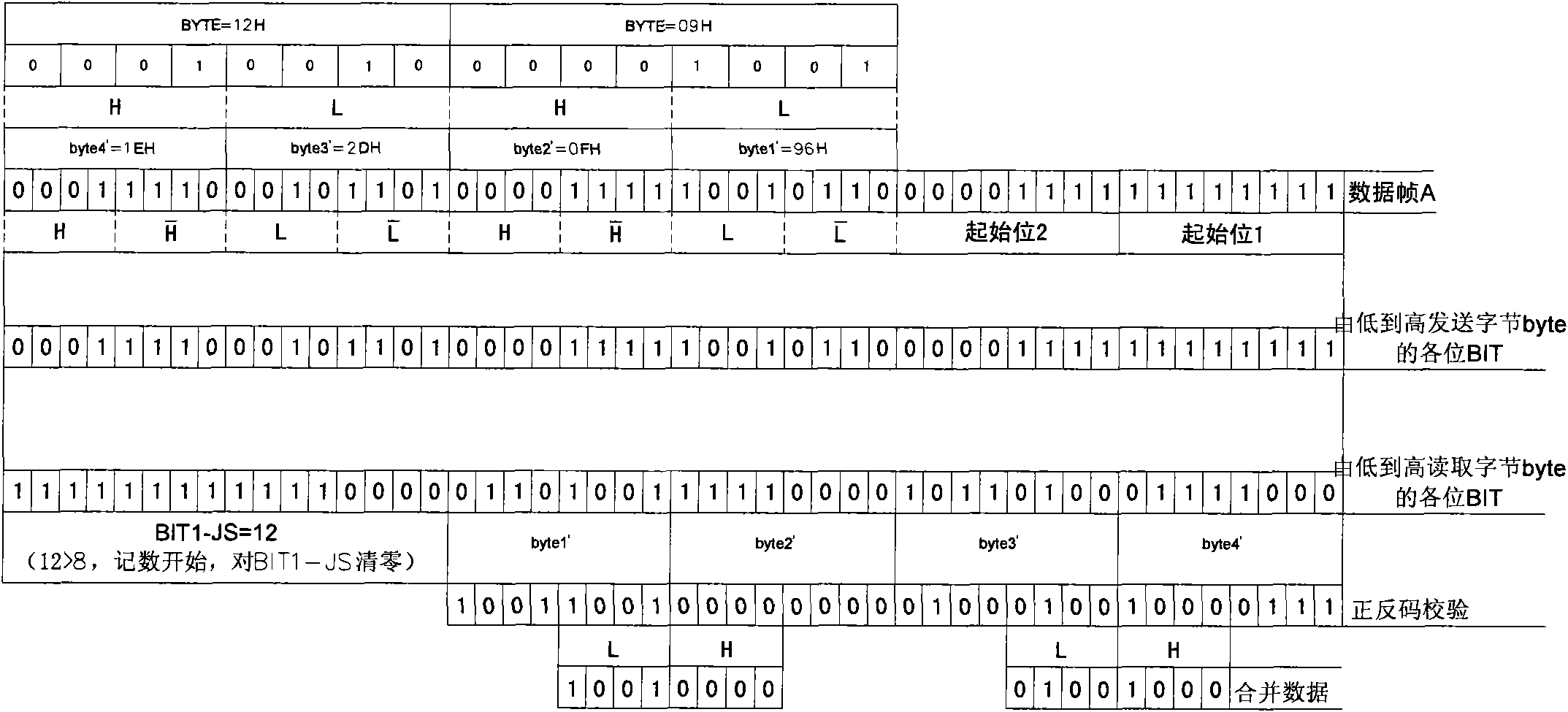

[0041] Such as figure 1 As shown, the present invention provides a verification system applied to electromagnetic cooker data communication, including an encoding end and a decoding end. The unencoded data is encoded with positive and negative codes to obtain a pair of encoded data, and the pair of encoded data is sent to the decoding end, and the decoding end performs positive and negative code decoding verification on each received data to obtain the verified data, and Restore the combination of two consecutive verified data into one decoded data. In this embodiment, the number of data bits to be encoded is 8 bits, that is, m=8.

[0042] Such as figure 1 As shown, the encoding method of the encoding end is as follows:

[0043] (21) Decomposing each uncoded data into a pair of coded data, which are respectively the first sent dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com