Automatic tap

A faucet, automatic technology, applied in the direction of engine components, valve details, electrical components, etc., can solve problems such as production efficiency impact, wire breakage, installation obstruction, etc., to achieve stable electrical contact, reduce requirements, and avoid the interference of internal wires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

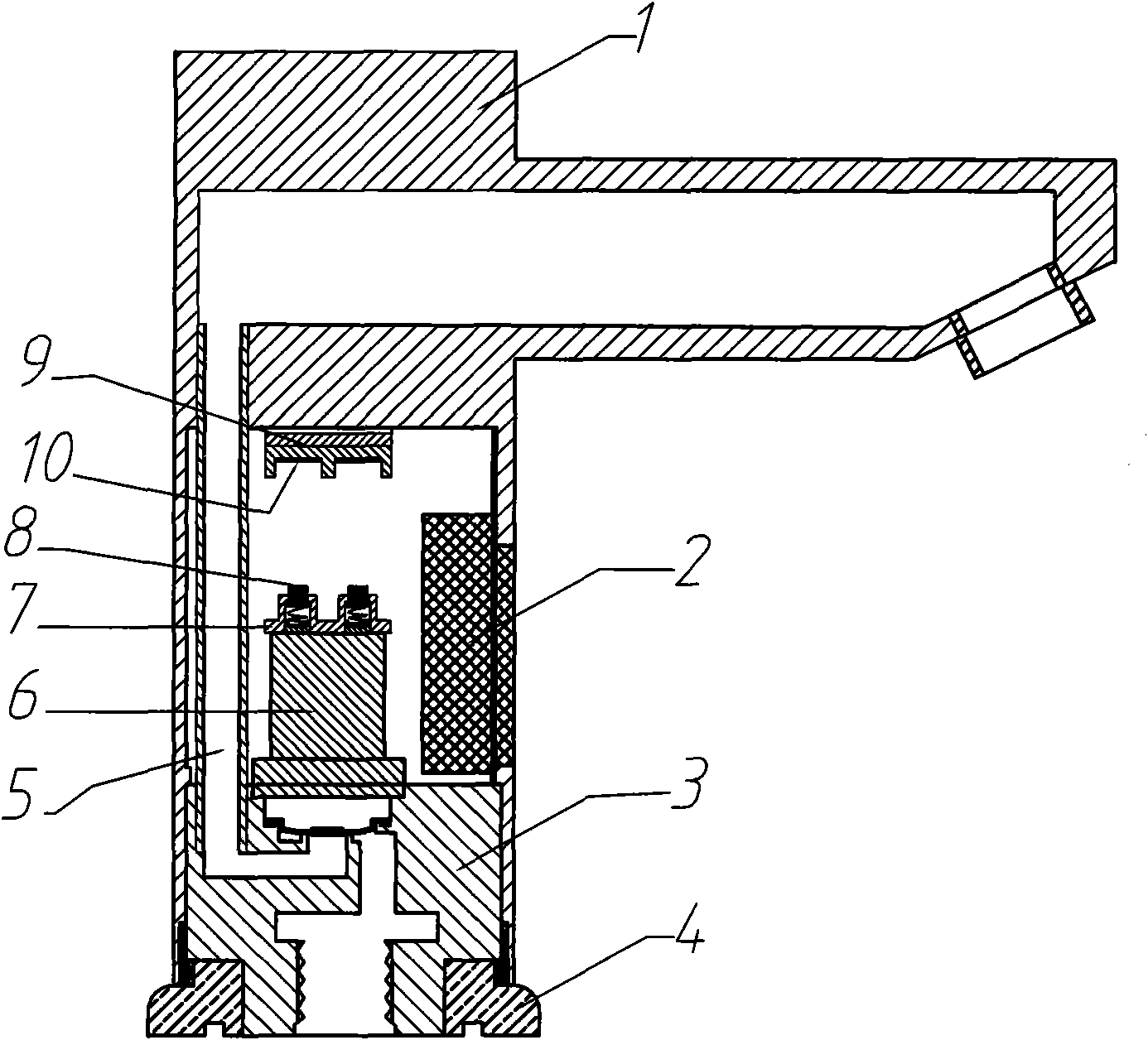

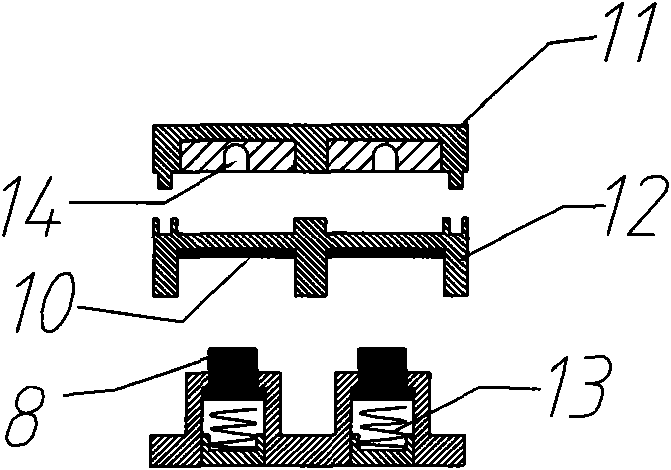

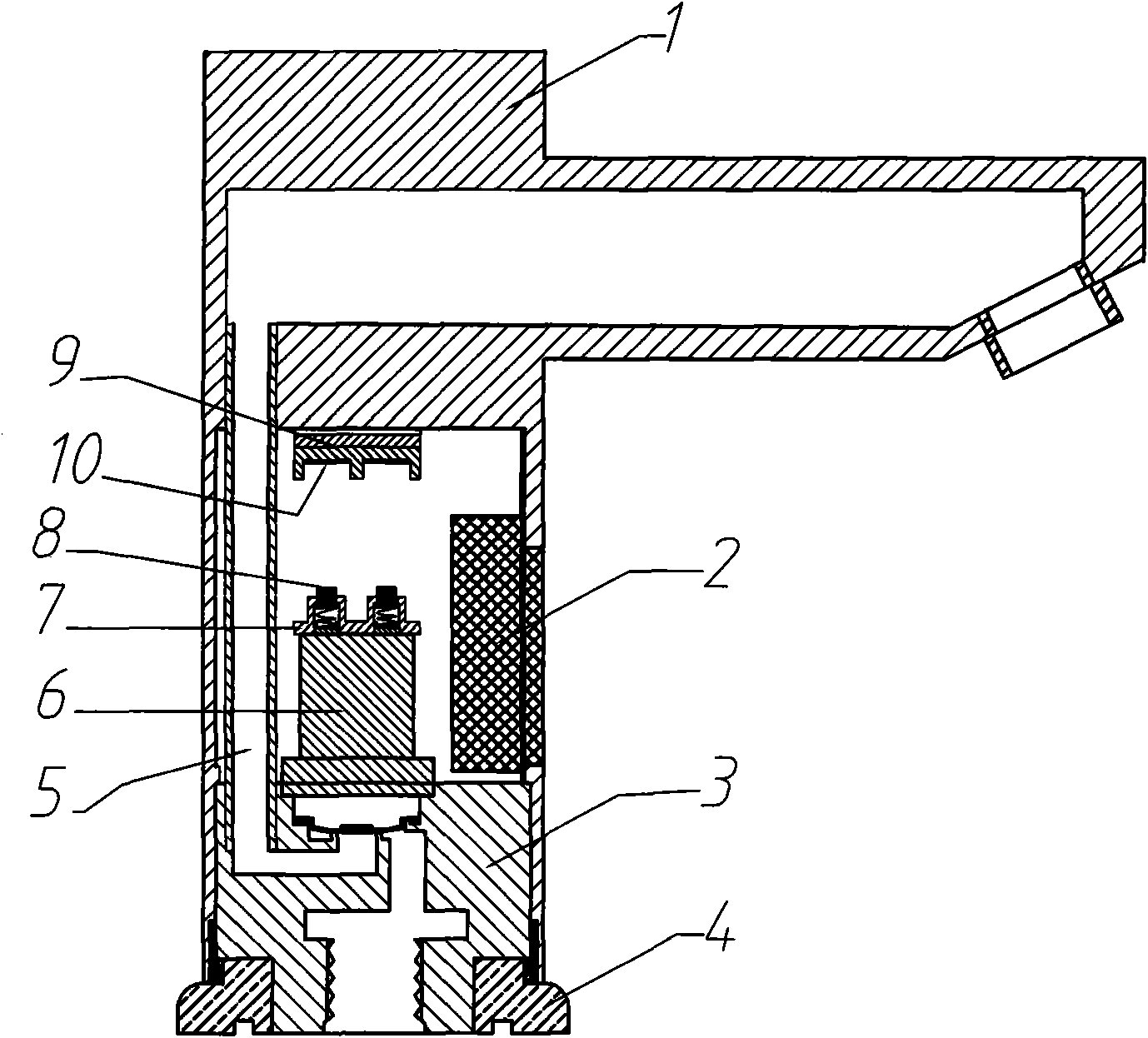

[0012] Referring to the accompanying drawings, this kind of automatic water faucet has a body (1), and the body (1) is equipped with an electronic induction device (2), a solenoid valve seat (3), a solenoid valve (6), and a water circuit of the solenoid valve seat (3). The pipeline (5) communicates with the waterway in the body (1), and the solenoid valve (6) is electrically connected to the electronic induction device (2), which is characterized in that the solenoid valve (6) is connected through the lower end electrical connection device (7) The upper end electrical connection device (9) is electrically connected to the electronic induction device (2), the lower end electrical connection device (7) is fixedly connected to the solenoid valve (6), and the upper end electrical connection device (9) is connected to the body (1) Fixed connection.

[0013] When the present invention is implemented, take the assembly of the automatic faucet electromagnetic valve as an example, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com