Combination balanced type standard device

A standard device and balanced technology, applied in measuring devices, calibration/testing of force/torque/power measuring instruments, instruments, etc., can solve problems such as sensitivity and stability cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

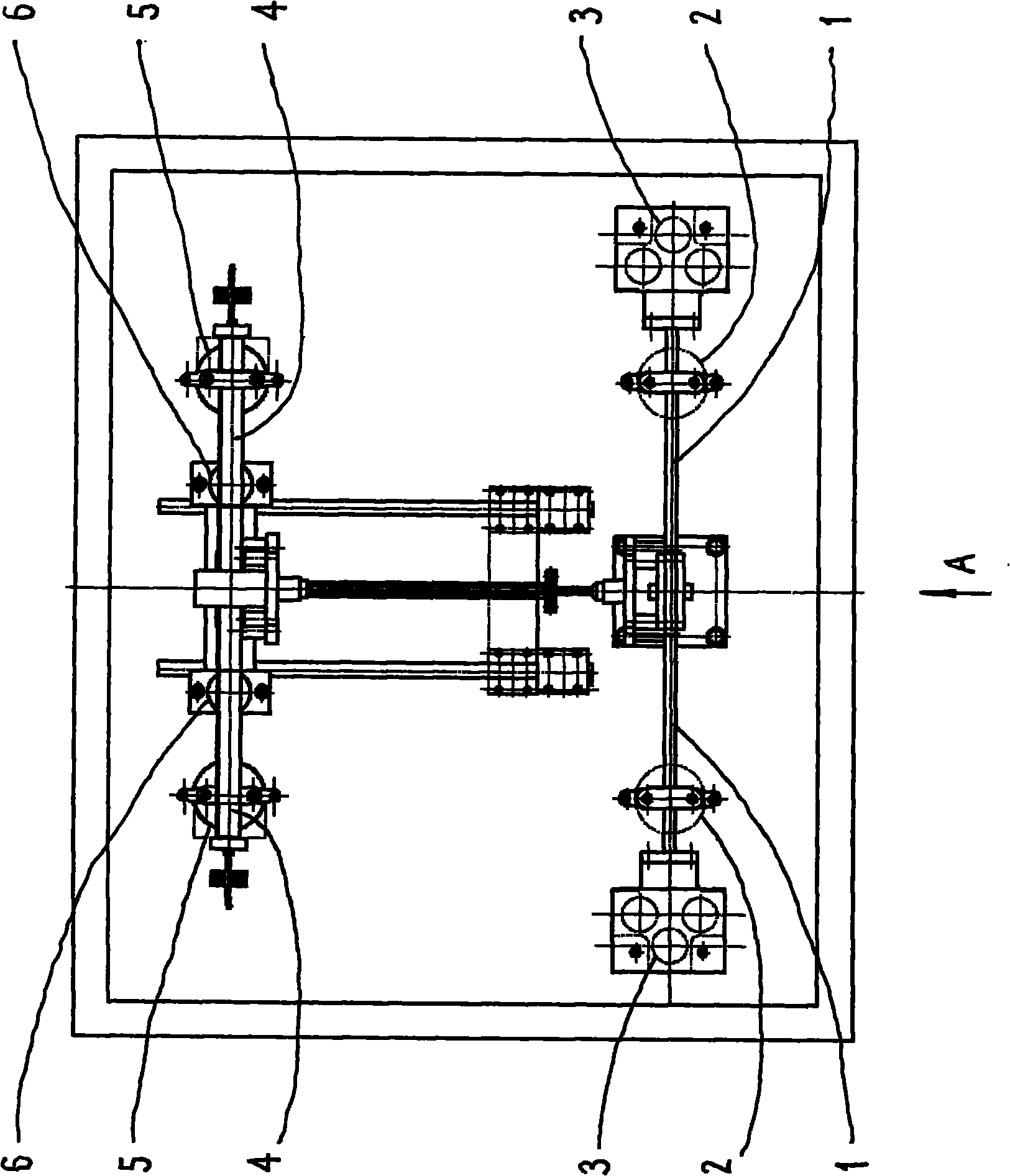

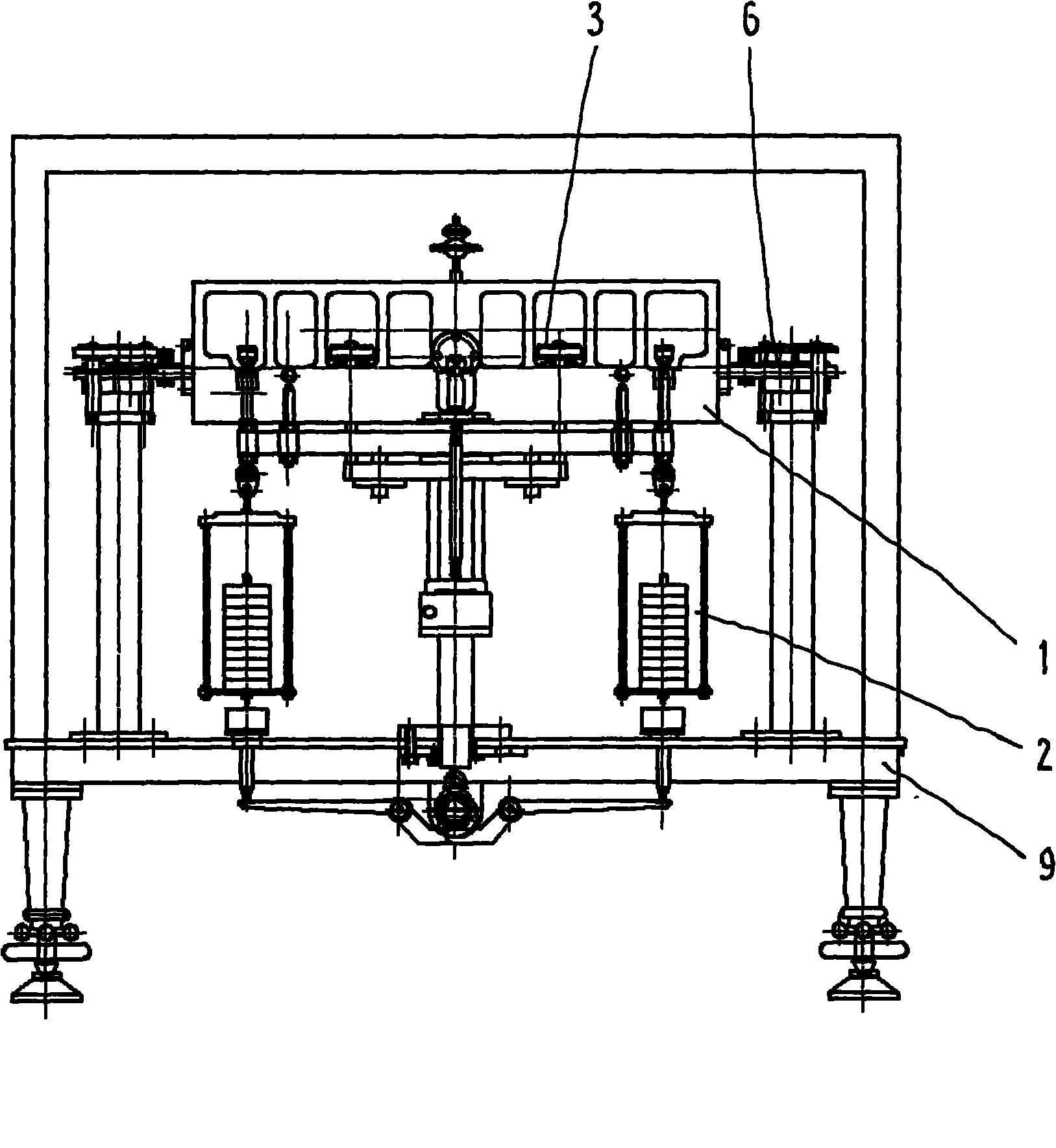

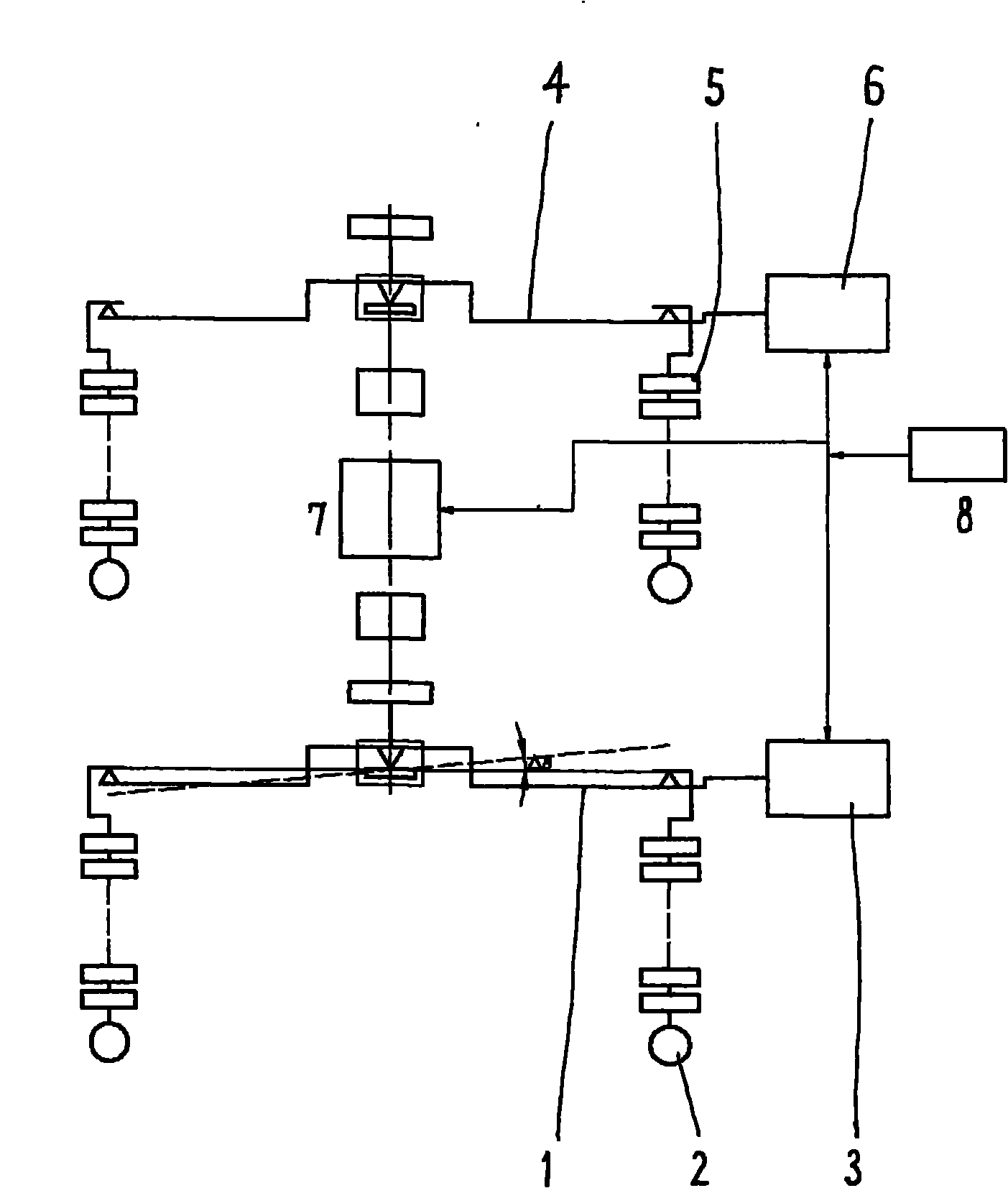

[0010] refer to figure 1 , 2 , 3. The combined balance standard device includes standard beam 1, front weight and weight loading 2, front electromagnetic force generator 3, balance beam 4, rear weight and weight loading 5, rear electromagnetic force generator 6, The measured sensor 7, the control solution system 8 and the pedestal 9.

[0011] The structure of the standard beam 1 is basically the same as that of the existing equipment, and can meet the high sensitivity requirements of the device.

[0012] The front weight and the weight loading 2 have basically the same structure as the existing equipment.

[0013] The front electromagnetic force generator 3 is one of the key components in the automatic balance system of the standard beam 1 with electromagnetic compensation torque, also known as the torque device, its structure is the same as the electromagnetic force generator of the precision electromagnetic balance, and its function is: when When the standard beam 1 is ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com