Press key modularized composite structure and blanking method thereof

A combined structure and modular technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of increasing equipment burden, time-consuming and labor-intensive, affecting assembly efficiency, and achieving the effect of efficient assembly operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

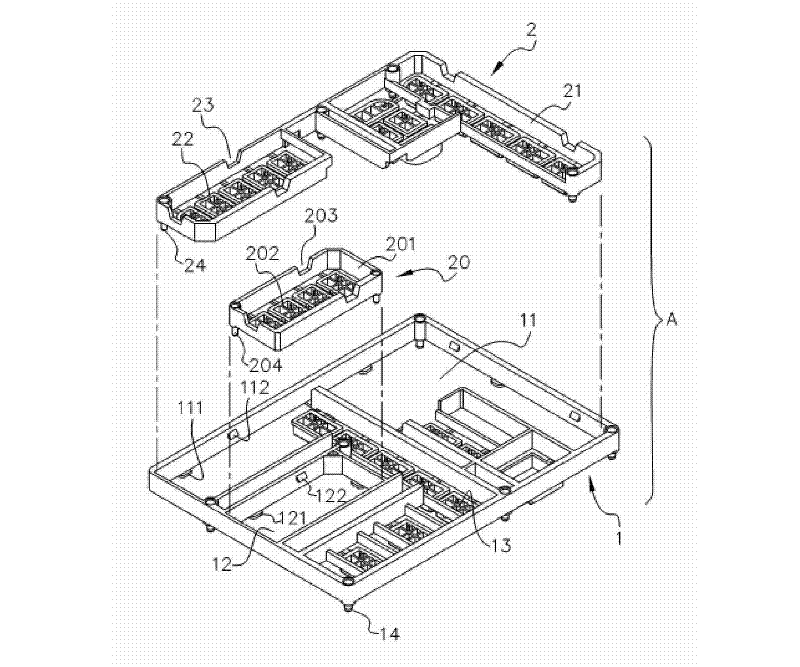

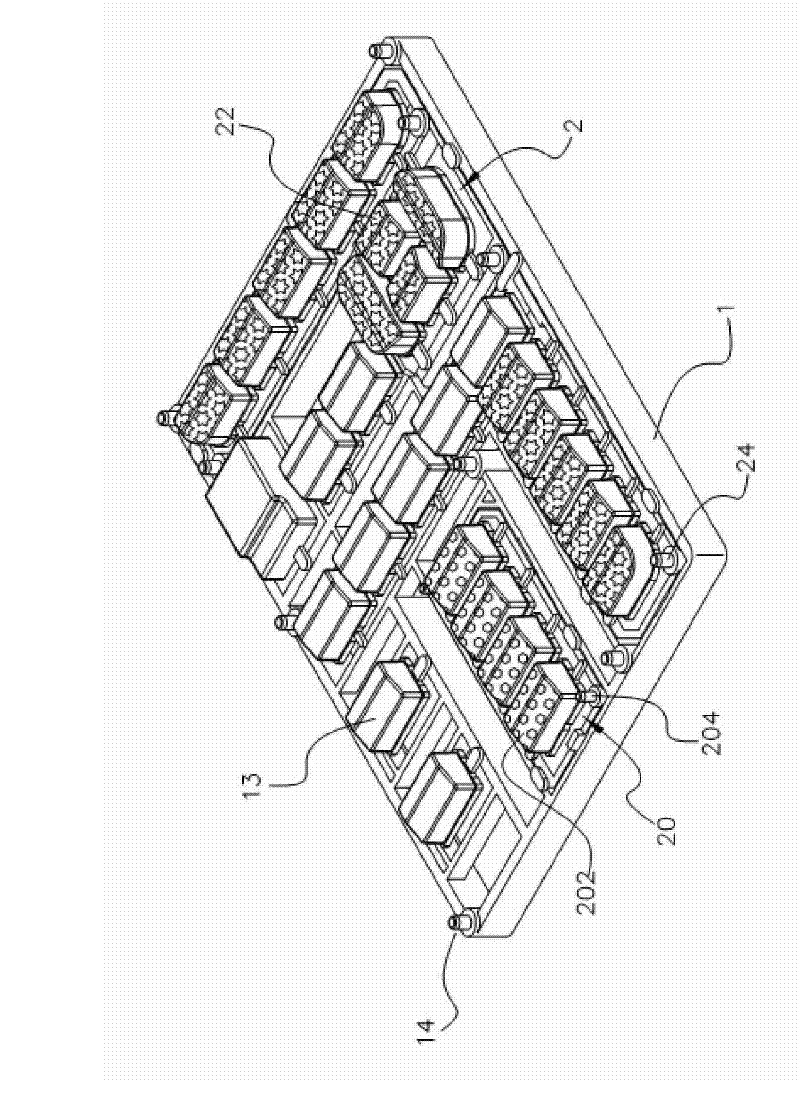

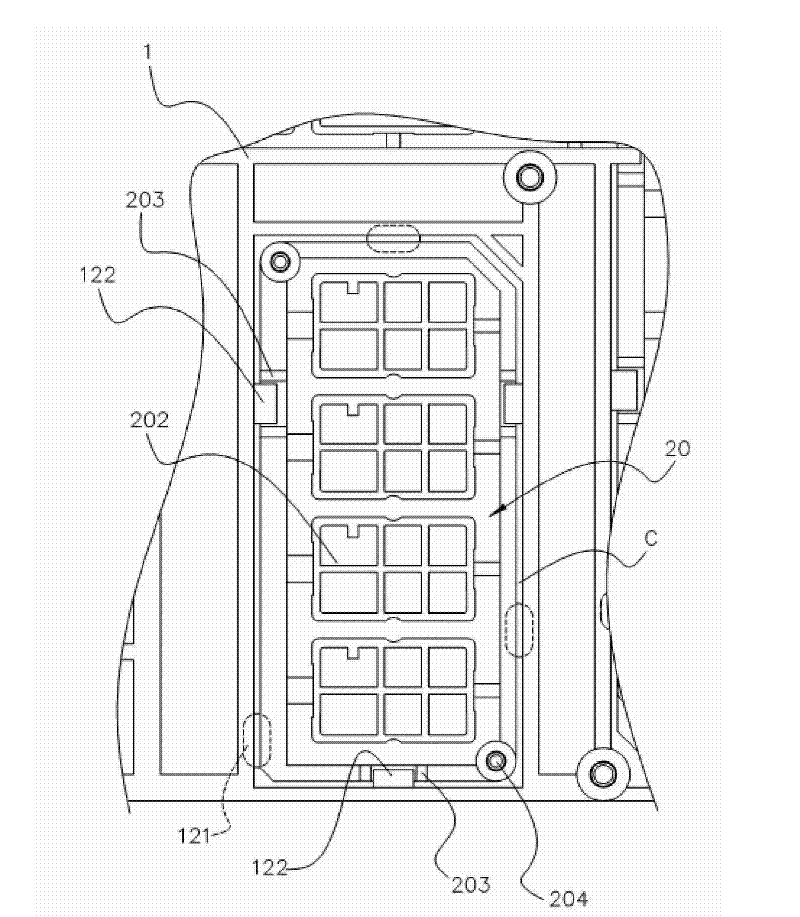

[0038] Please refer to Figure 1 to Figure 3 As shown, it can be clearly seen that the structure of the button module assembly A of the present invention mainly includes: a module frame 1 and at least one button module (the icon has two buttons such as the first button module 2 and the second button module 20) module), the inside of the module frame 1 can match the number of each key module and be provided with at least one accommodating area (the figure shows two accommodating areas such as the first accommodating area 11 and the second accommodating area 12) area), and a plurality of inwardly protruding stop portions 111, 121 are provided on the bottom side of the periphery of the first and second accommodating areas (11, 12). A plurality of guiding and positioning projections 112, 122 with beveled surfaces on the top side are respectively provided at the positions with appropriate spacing, and other positions of the module frame 1 other than the first and second accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com