Shear wall multifunctional positioning element

A multi-functional, positioning component technology, applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of increasing construction costs, insufficient bending strength, affecting construction accuracy, etc., to achieve easy construction and installation, self-lubricating Good, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

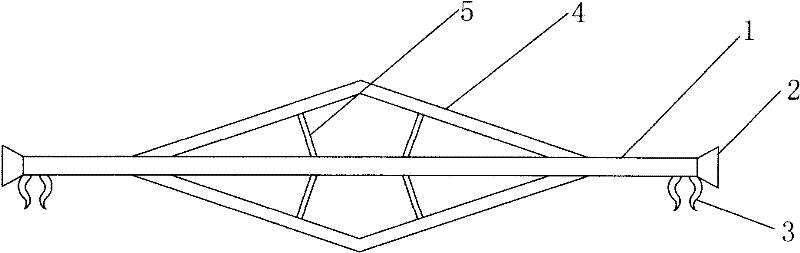

[0019] Such as figure 1 As shown, a multifunctional positioning member for a shear wall includes a positioning rod 1, pads 2 are provided at both ends of the positioning rod 1, and a hook 3 is provided on the positioning rod 1 inside the two pads 2, and the two hooks 3 Several herringbone ribs 4 uniformly distributed in the circumferential direction are arranged on the positioning rod 1 inside. The cross-sectional shape of positioning rod 1 is any one in circle, square, triangle, regular polygon, preferably with circle, and positioning rod 1 is a solid rod body; The cross-sectional shape of rib 4 is circular, square, triangular, Any one of regular polygons, circle and square are preferred. The positioning rod 1, the spacer 2, the hook 3 and the reinforcing rib 4 are of an integrated structure and are made of engineering plastics. The shape of the spacer 2 is a circular platform with a large outside and a small inside, and its interface shape is an isosceles trapezoid. The h...

Embodiment 2

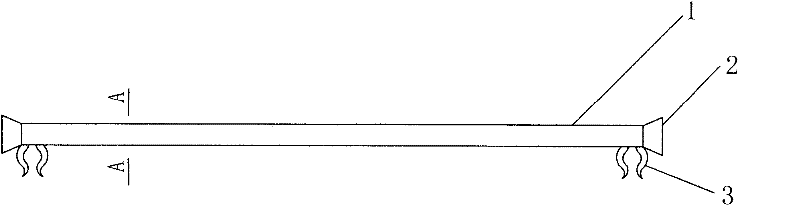

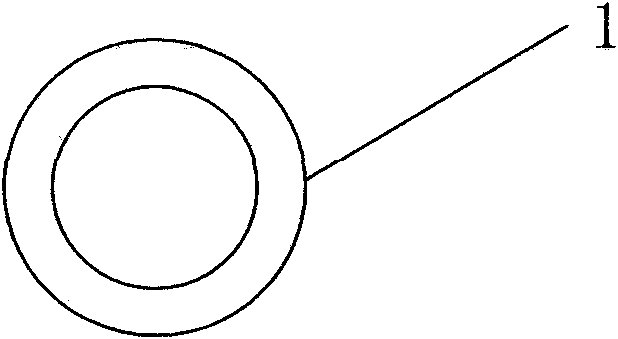

[0021] Such as figure 2 , image 3 As shown, a multifunctional positioning member for a shear wall, the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the positioning rod 1 is a hollow rod body, and no reinforcing ribs are added on the positioning rod 1, in order to ensure that the positioning member The strength of bending resistance, so when making, the outer diameter of the positioning rod 1 of this embodiment is relatively larger than the diameter of the positioning rod 1 in embodiment 1. The solution of this embodiment is: including positioning rod 1, positioning rod 1 Pads 2 are provided at both ends of the two pads 2, and a hook 3 is provided on the positioning rod 1 inside the two pads 2. The positioning rod 1 adopts a rod body with a hollow structure in the middle, and the external profile of the rod is still circular, square, triangular, positive Either of the polygons, image 3 It is the cross-sectional shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com