Multi-thread threading sealing sheath

A sealing sheath and threading technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as unstable circuit operation, access, and relatively high requirements for the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

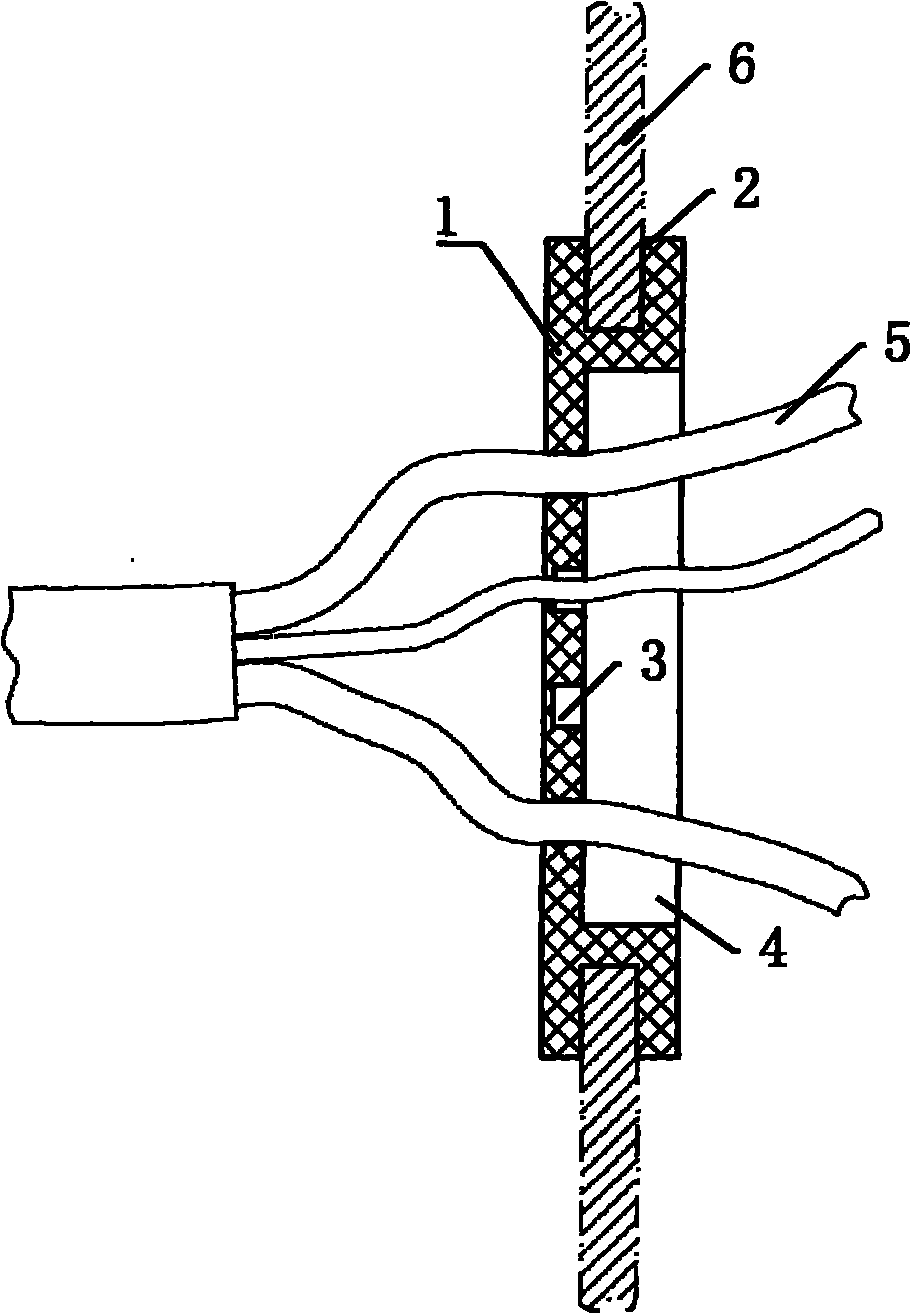

[0021] Such as figure 1 As shown, the multi-wire threading sealing sheath includes a rubber sheath body 1, the outer periphery of the sheath body 1 is provided with a sealing connection device connected to the electrical box housing 6, and the sealing connection device is located on the sheath body The clamping groove 2 on the outer periphery is provided with a groove 4 on the sheath body 1, and at least two threading holes are arranged at the bottom of the groove 4. The threading holes are blind holes 3, and the blind holes 3 are cylindrical blind holes , each blind hole 3 is equal in size, and all blind holes 3 are evenly arranged on the sheath body 1 .

[0022] When used, such as figure 1 As shown, the wire 5 is passed through the blind hole 3 from the bottom of the blind hole 3. Since the sheath body 1 is made of rubber material, the bottom of the blind hole 3 has a good sealing and fixing protection effect on the passing wire 5 . The diameter of blind hole 3 is slightl...

Embodiment 2

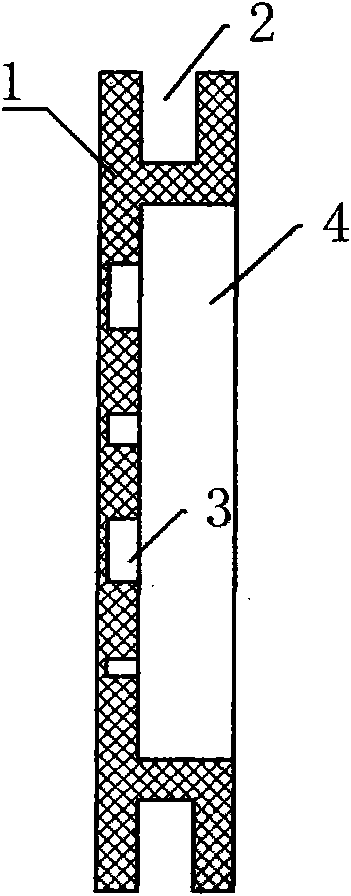

[0024] Such as figure 2 As shown, the multi-wire threading sealing sheath includes a rubber sheath body 1, the outer periphery of the sheath body 1 is provided with a sealing connection device connected to the electrical box housing 6, and the sealing connection device is located on the sheath body The clamping groove 2 on the outer periphery is provided with a groove 4 on the sheath body 1, and at least two threading holes are arranged at the bottom of the groove 4. The threading holes are blind holes 3, and the blind holes 3 are cylindrical blind holes , each blind hole 3 has a different size, and all the blind holes 3 are evenly arranged on the sheath body 1 .

[0025] In practical applications, the wires 5 of the instrument panel may have different thicknesses. If the diameters of the blind holes 3 are equal, the diameters of these blind holes 3 will be too small for the thicker wires 5, and the diameters for the thinner wires will be too small. 5, the diameter is too la...

Embodiment 3

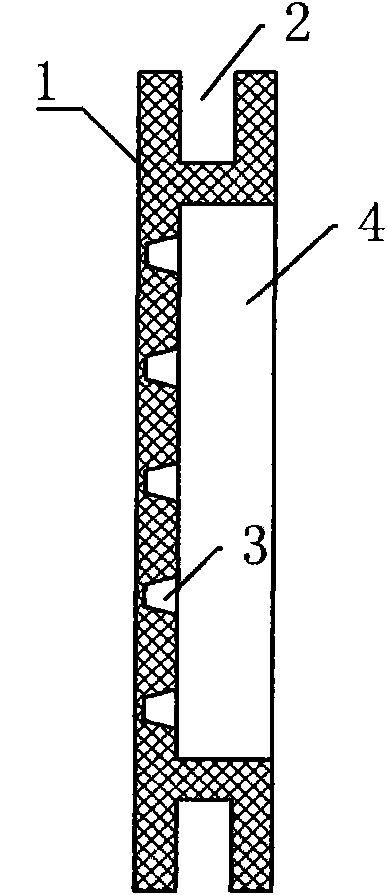

[0027] Such as image 3 As shown, the multi-wire threading sealing sheath includes a rubber sheath body 1, the outer periphery of the sheath body 1 is provided with a sealing connection device connected to the electrical box housing 6, and the sealing connection device is located on the sheath body The clamping groove 2 on the outer periphery is provided with a groove 4 on the sheath body 1, and at least two threading holes are arranged at the bottom of the groove 4, and the threading holes are blind holes 3, and the blind holes 3 are conical blind holes , each blind hole 3 is equal in size, and all blind holes 3 are evenly arranged on the sheath body 1 .

[0028] When the blind hole 3 is set in a conical shape, the conical blind hole has better sealing adaptability to the passing electric wires.

[0029] Of course, like the second embodiment, the sizes of the conical blind holes 3 in the third embodiment may also be different, and this technical solution will not be repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com